Novel diamond grinding wheel with small section and multiple tool bits

A multi-cutter, diamond technology, applied in the direction of abrasives, bonded grinding wheels, metal processing equipment, etc., can solve the problem of low strength of the cutter head, and achieve the effect of good heat dissipation, fast speed and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

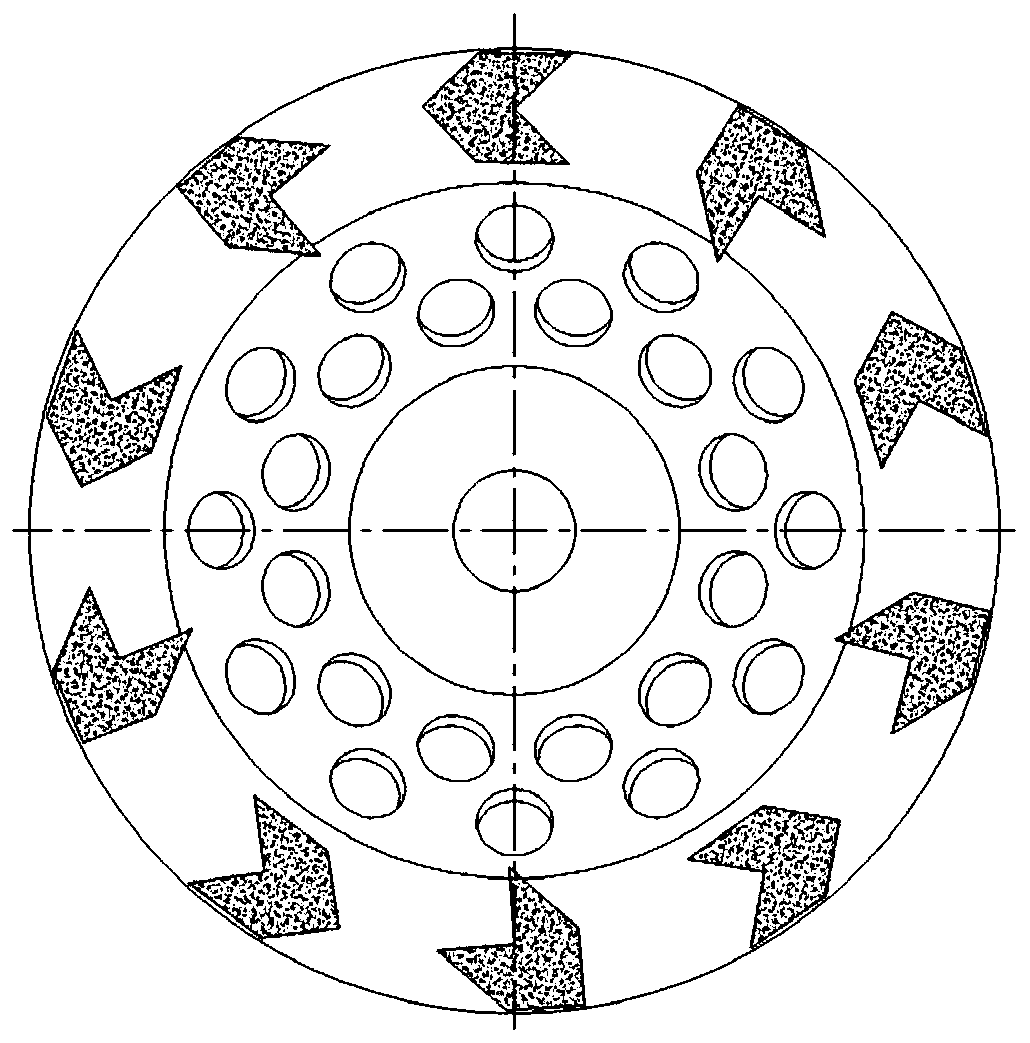

[0024] This embodiment proposes a new type of diamond grinding wheel with a small cross-section and multiple cutter heads, such as Figure 5 As shown, it includes a base body 1, and a plurality of cutter heads 2 are arranged at intervals around the periphery of the base body, and the cross-sectional area of the cutter head is 4-65mm 2 , The distance between two adjacent cutter heads is 5mm-20mm.

[0025] The cutter head is provided with three groups, and each group of cutter heads is arranged at intervals along the circumference of the substrate by several cutter heads, and the diameters of the circles formed by adjacent two groups of cutter heads are different, and the cross-section of each group of cutter heads is the same, and the three groups of cutter heads 2-1, 2-2, 2-3, from the inner side of the base body to the outer side, the cross-sectional area of the cutter head increases successively. The cross-sectional area of the cutter head is triangular.

[0026] exi...

Embodiment 2

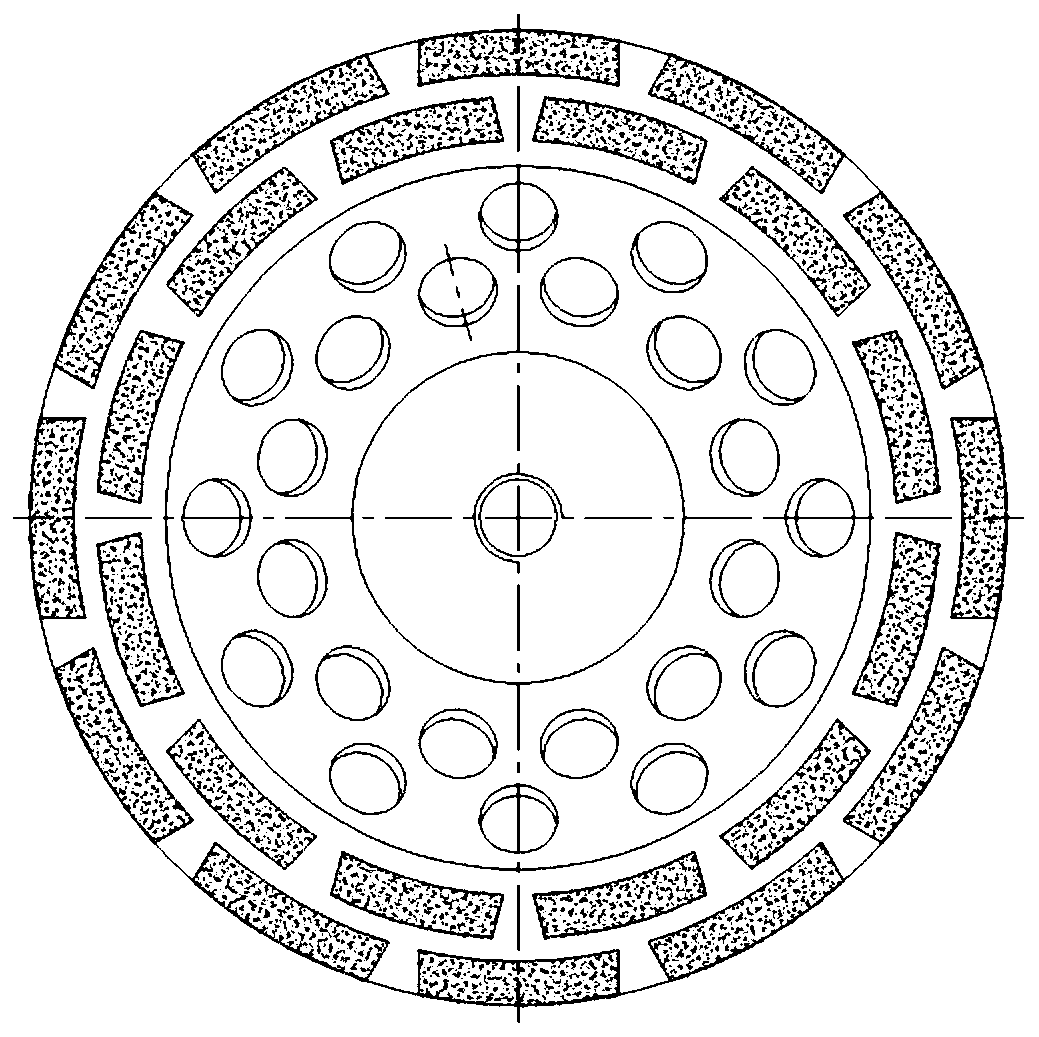

[0030] This embodiment proposes a new type of diamond grinding wheel with a small cross-section and multiple cutter heads, such as Figure 6 As shown, including a base body, a plurality of cutter heads are arranged at intervals around the periphery of the base body, and the cross-sectional area of the cutter head is 4-65mm 2 , The distance between two adjacent cutter heads is 5mm-20mm.

[0031] There are three groups of cutter heads, and each group of cutter heads consists of several cutter heads arranged at intervals along the circumference of the substrate, and the diameters of the circles formed by two adjacent groups of cutter heads are different. The cross-sectional area of the cutting head of two adjacent groups of cutting heads is different, and the cross-sectional area of the cutting head of each group of cutting heads is the same, and the cross-sectional area of the cutting head of the three groups of cutting heads increases from the inner side to the outer si...

Embodiment 3

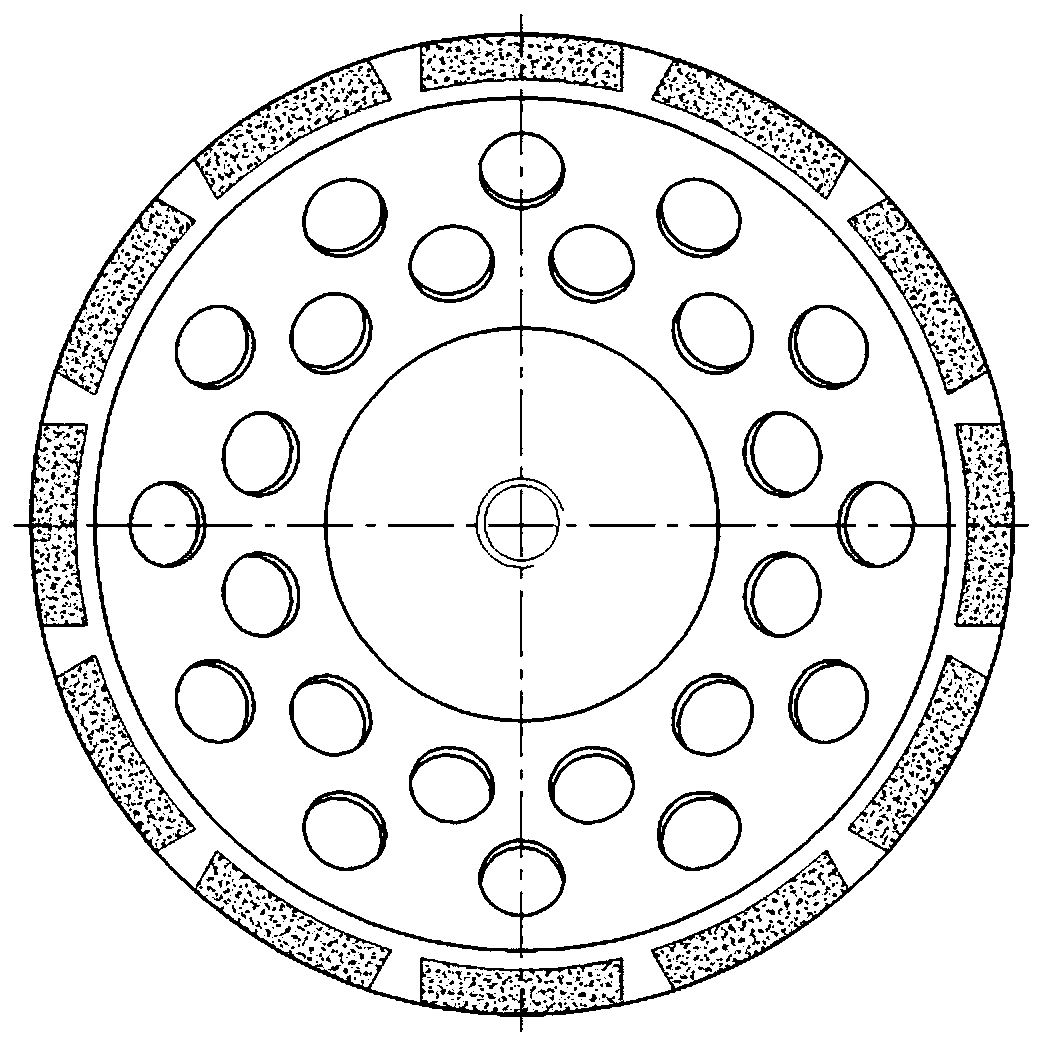

[0036] This embodiment proposes a new type of diamond grinding wheel with a small cross-section and multiple cutter heads, such as Figure 7 As shown, including a base body, a plurality of cutter heads are arranged at intervals around the periphery of the base body, and the cross-sectional area of the cutter head is 4-65mm 2 , The distance between two adjacent cutter heads is 5mm-20mm.

[0037] There are two groups of cutter heads, and each group of cutter heads consists of several cutter heads arranged at intervals along the circumference of the substrate, and the diameters of the circles formed by adjacent two groups of cutter heads are different. The cross-sectional area of the cutting head of two adjacent groups of cutting heads is the same, and the cross-sectional area of the cutting head of each group of cutting heads is the same, and the cross-sectional area of the cutting head is circular.

[0038] Example 3 Figure 7 The shown grinding wheel goes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com