Floor cleaning machine using micro-fiber pad

a floor cleaning machine and microfiber technology, applied in the field of floor cleaning machines, can solve the problems of requiring the use of separate vacuum and scrubbers, consuming considerable time for vacuuming and scrubbing in tandem, and high cost of automatic scrubbers, so as to reduce the size of the machine and achieve the effect of reducing the design application area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

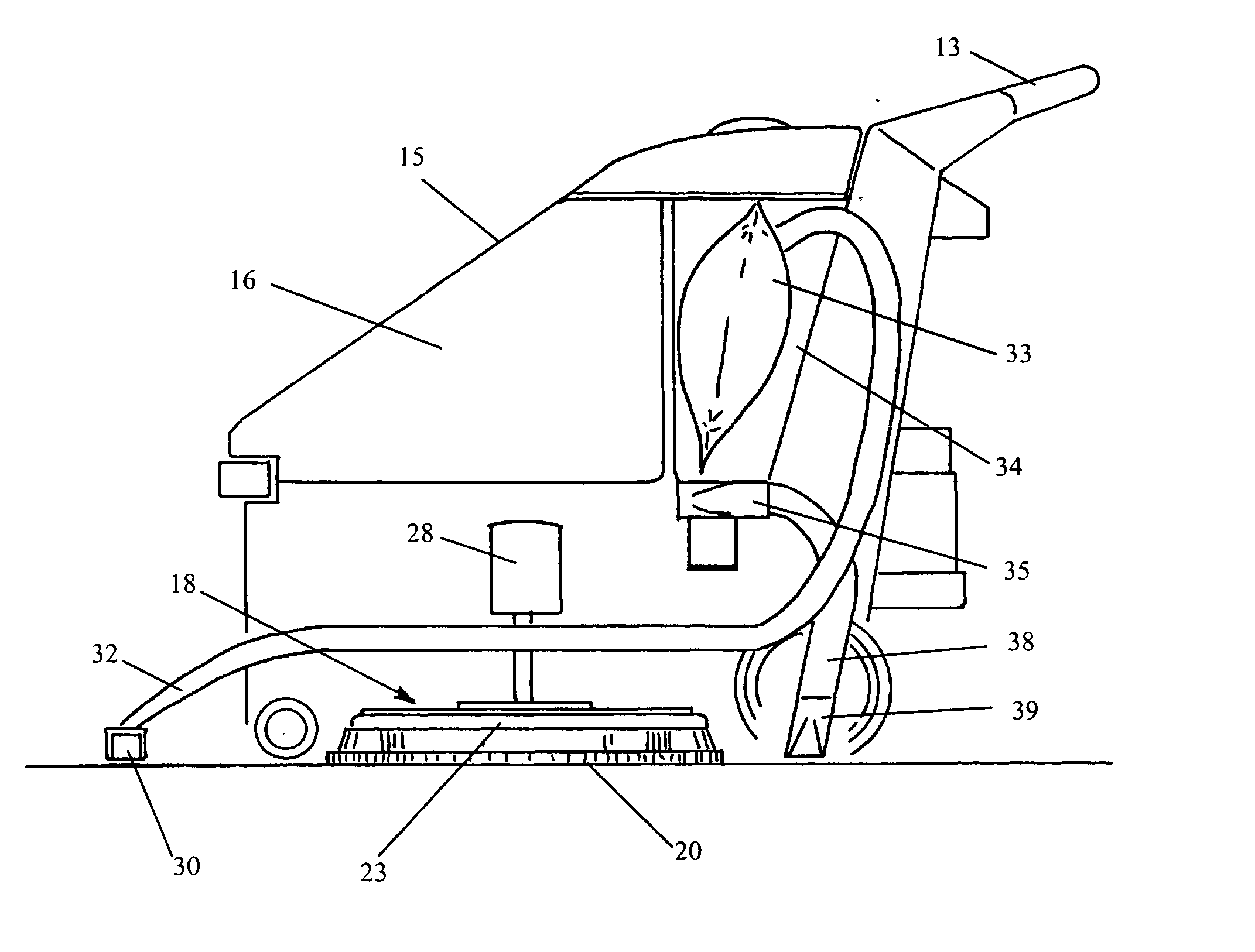

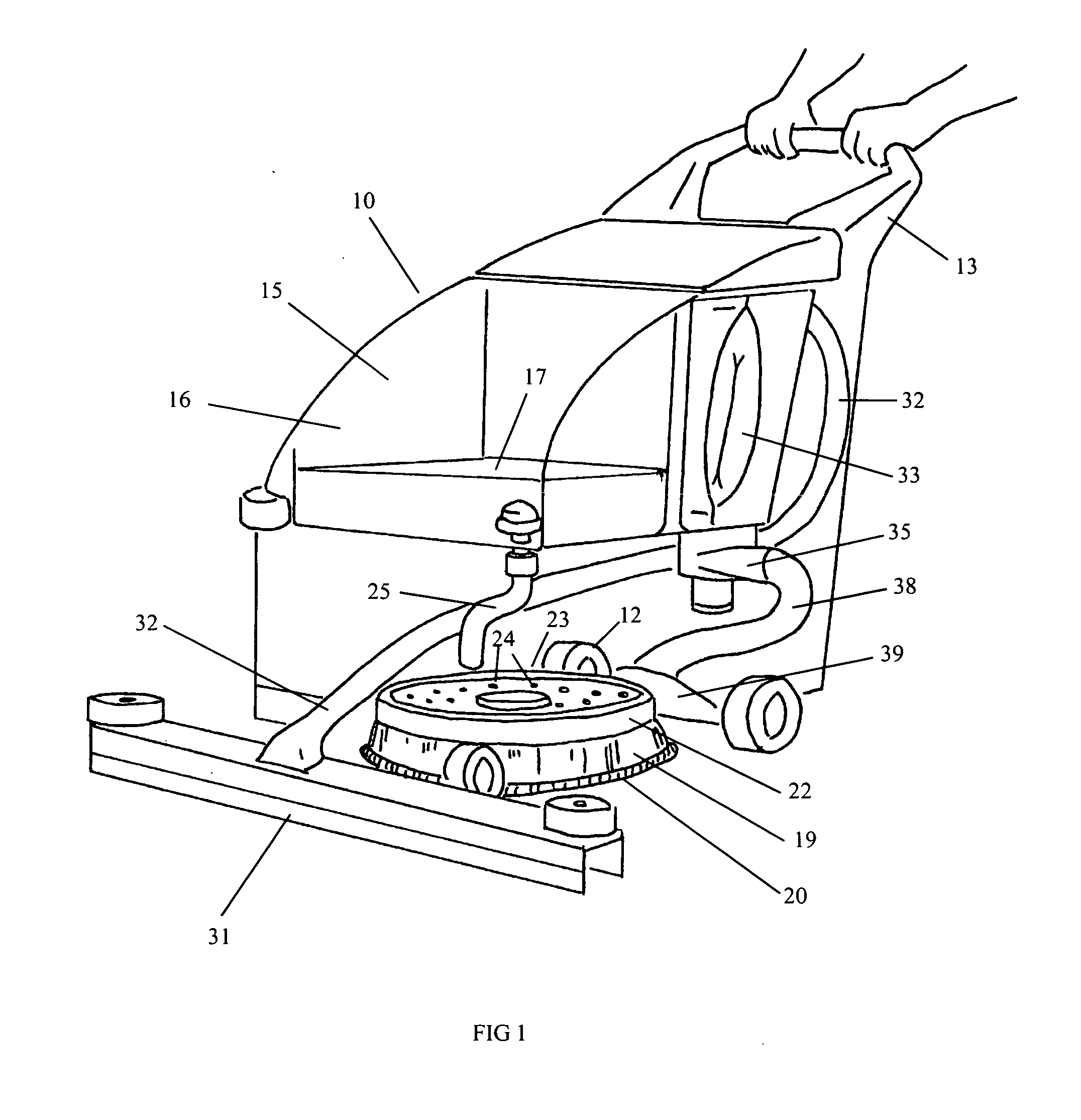

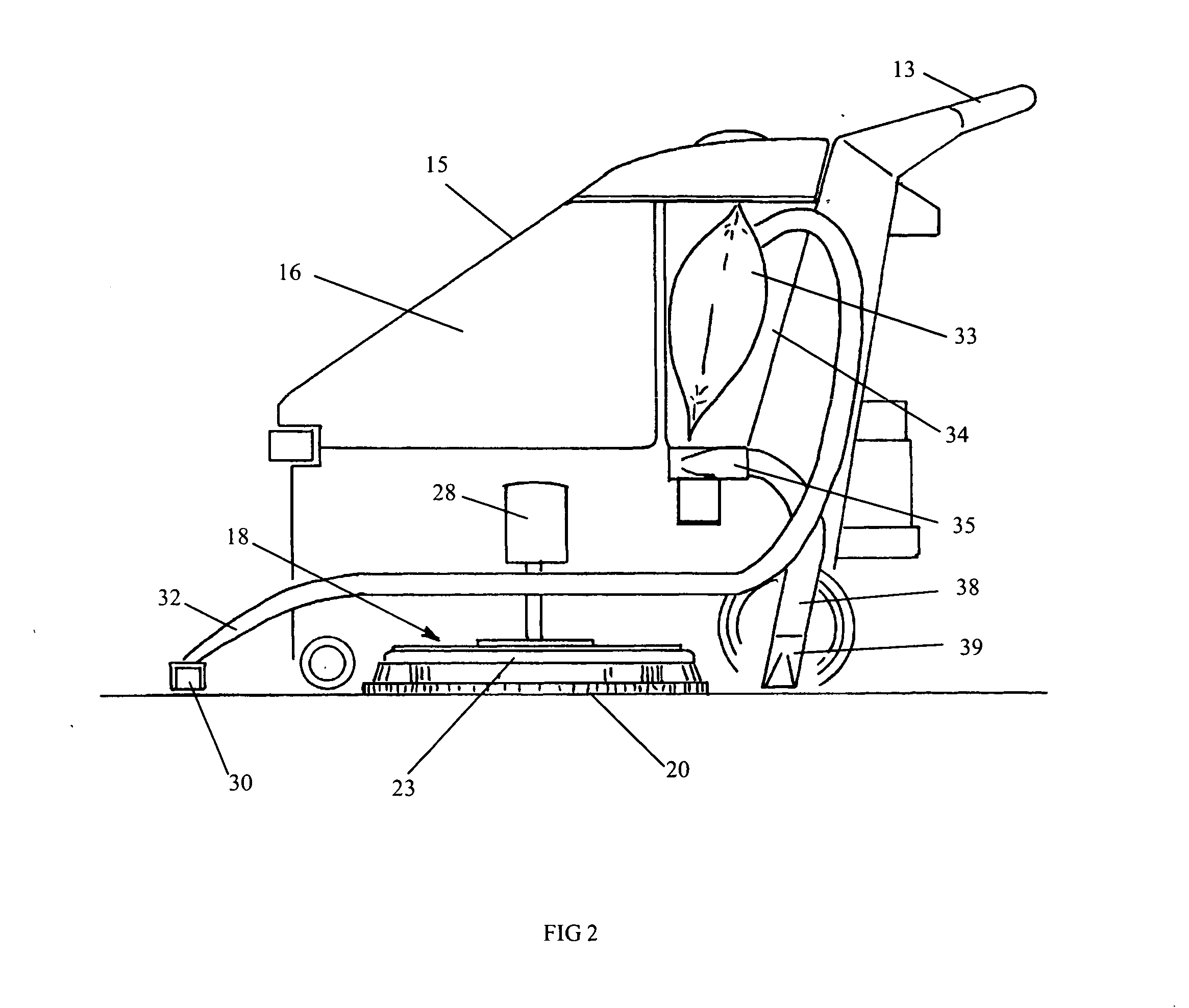

[0019] Referring first to FIG. 1, reference numeral 10 generally designates a floor scrubbing machine having a frame for supporting the various elements. The machine 10 includes forward and rear support wheels 12; and in the illustrated embodiment, the wheels are not driven by a motor. Rather, the machine is pushed by an operator standing behind the machine and grasping the handle 13, urging the machine in a leftward direction in FIG. 2 and a generally leftward and slightly toward the viewer in FIG. 1.

[0020] The machine 11 also includes an outer casing 15 in which there is formed a solution tank generally designated 16 for receiving a quantity of liquid cleaning solution or clean water 17. Beneath the machine 10 and carried by the frame is a pad assembly generally designated 18, in FIG. 2, and including a pad driver 19 and a micro fiber pad 20 attached to, or otherwise secured beneath, the pad driver 19.

[0021] The micro fiber pad 20 includes a lower layer of micro fiber sheet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com