Device and method for preparing spherical titanium powder and titanium alloy powder through gas atomization

A spherical titanium powder and gas atomization technology, applied in the powder metallurgy industry, can solve the problems of coarse particle size, low efficiency and poor continuity, and achieve the effects of controllable particle size, low impurity content and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

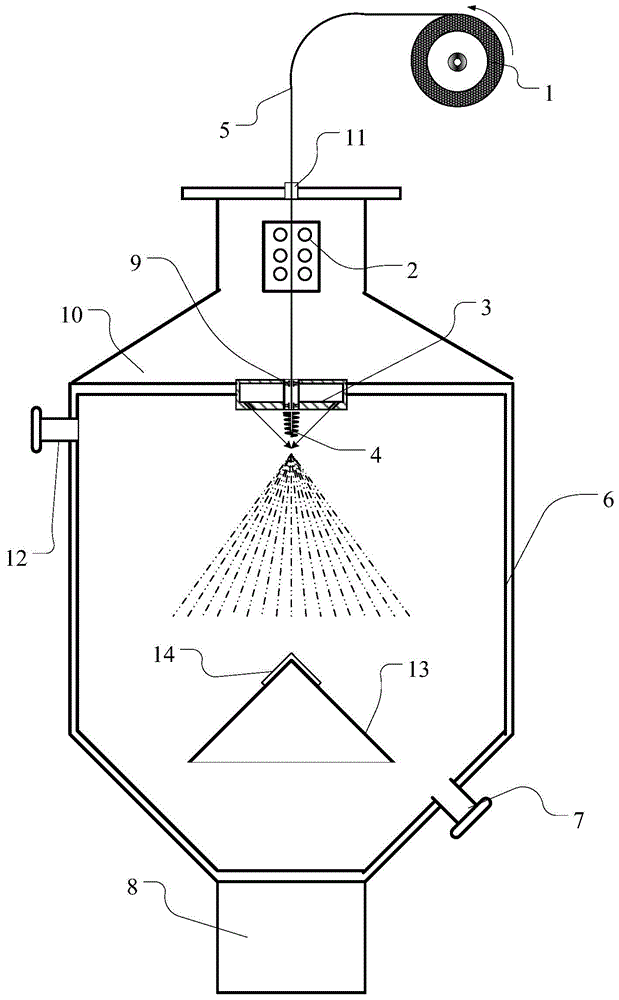

[0040] The preparation method for preparing spherical titanium powder and titanium alloy powder by gas atomization of the present invention includes preparation processes such as wire feeding, high-frequency melting induction, atomization, droplet spheroidization, and cooling and solidification. The method includes the following specific steps:

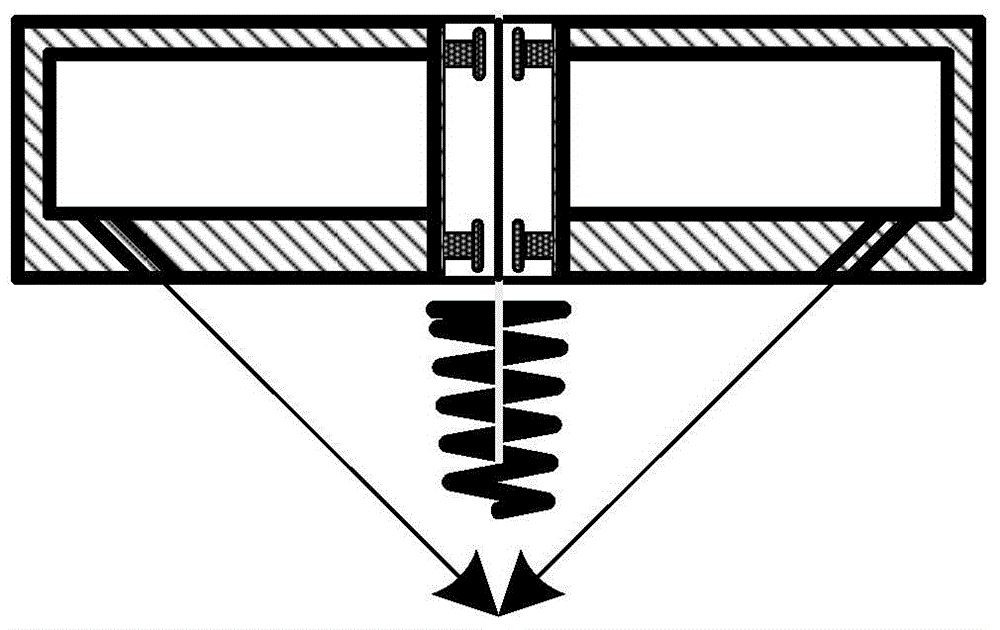

[0041] (1) The titanium or titanium alloy wire / rod 5 is sent to the vacuum chamber 10 by the continuous feeder 1 through the dynamic sealing device 11, and after being straightened by the metal straightening mechanism 2 in the vacuum chamber 10, it is passed through the gas atomization nozzle 3 The guide device 9 in the central hole reaches the inside of the high-frequency melting coil 4, and the wire / rod material used can be pure titanium, Ti6Al4V and other traditional titanium materials for powder metallurgy, or new functional materials such as TiNiCuZr;

[0042] (2) Vacuumize the whole set of powder making device, including atomizat...

Embodiment 1

[0048] Firstly, pure titanium wire with a diameter of Ф2mm of the national standard TA1 grade is selected, and the titanium wire is straightened by a continuous feeding mechanism and then sent to the inside of the melting coil. Then vacuumize the whole set of equipment, and the vacuum degree reaches 1×10 -5 After Pa, use high-purity argon as the protective gas to recoil into the equipment, and the internal gas pressure of the equipment is 0.10MPa. Use a high-frequency power supply to heat and melt the titanium wire. The melting power is 20KW and the frequency is 500KHz. After the titanium wire is melted, the melt temperature exceeds the melting point of 200°C. After the titanium wire melts to form a stable liquid melt flow, it passes through the gas mist The atomizing nozzle atomizes the metal liquid flow to make powder. The atomization medium is high-purity argon, the atomization pressure is 4.0MPa, and the atomization gas flow rate is 90L / S. The melt droplets are broken, s...

Embodiment 2

[0050] Firstly, select Ti-6Al-4V titanium alloy wire with a diameter of Ф8mm, straighten the wire through a continuous feeding mechanism, and then send it to the inside of the melting coil. Then vacuumize the whole set of equipment, and the vacuum degree reaches 1×10 -4 After Pa, use high-purity argon as the protective gas to recoil into the equipment, and the internal gas pressure of the equipment is 0.1MPa. Use a high-frequency power supply to heat and melt the titanium wire. The melting power is 20KW and the frequency is 700KHz. After the titanium wire is melted, the melt temperature exceeds the melting point of 150°C. After the titanium wire melts to form a stable liquid melt flow, it passes through the gas mist The atomizing nozzle atomizes the metal liquid flow to make powder. The atomization medium is high-purity argon, the atomization pressure is 6.0MPa, and the atomization gas flow rate is 120L / S. The melt droplets are broken, spheroidized, cooled and solidified by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com