Fe-based composite particle temperature-resisting absorbent and preparing method thereof

A technology of composite particles and absorbents, applied in metal processing equipment, electrical components, transportation and packaging, etc., can solve the problem of affecting the electromagnetic parameters and absorbing performance of nanocrystalline carbonyl iron powder, and cannot realize the grain structure of nanocrystalline carbonyl iron powder Stability, grain growth and other issues, to achieve stable grain size, good temperature resistance, and improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

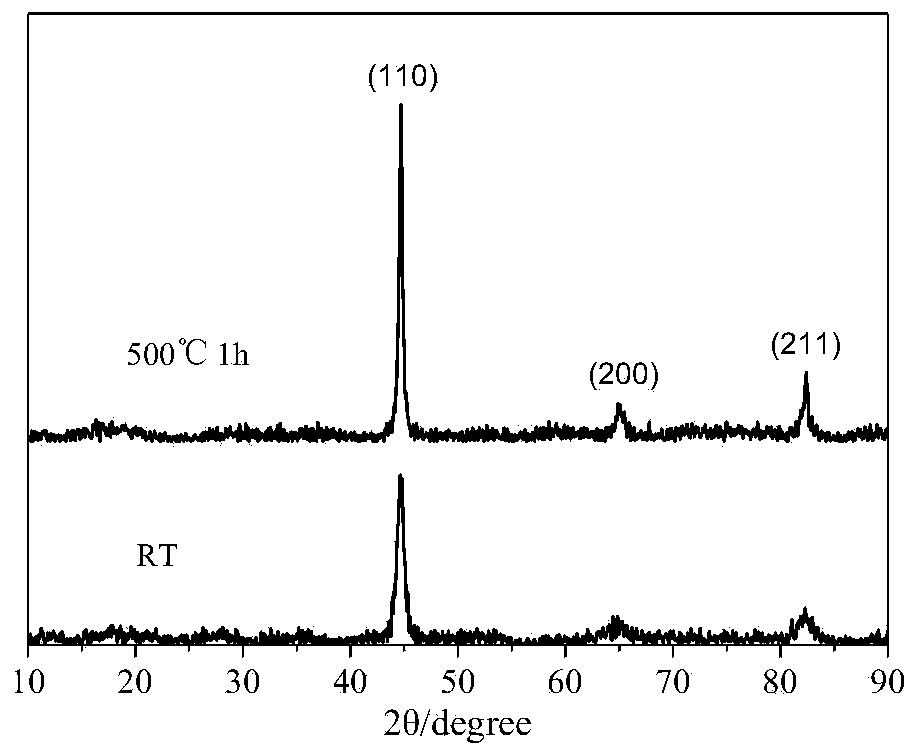

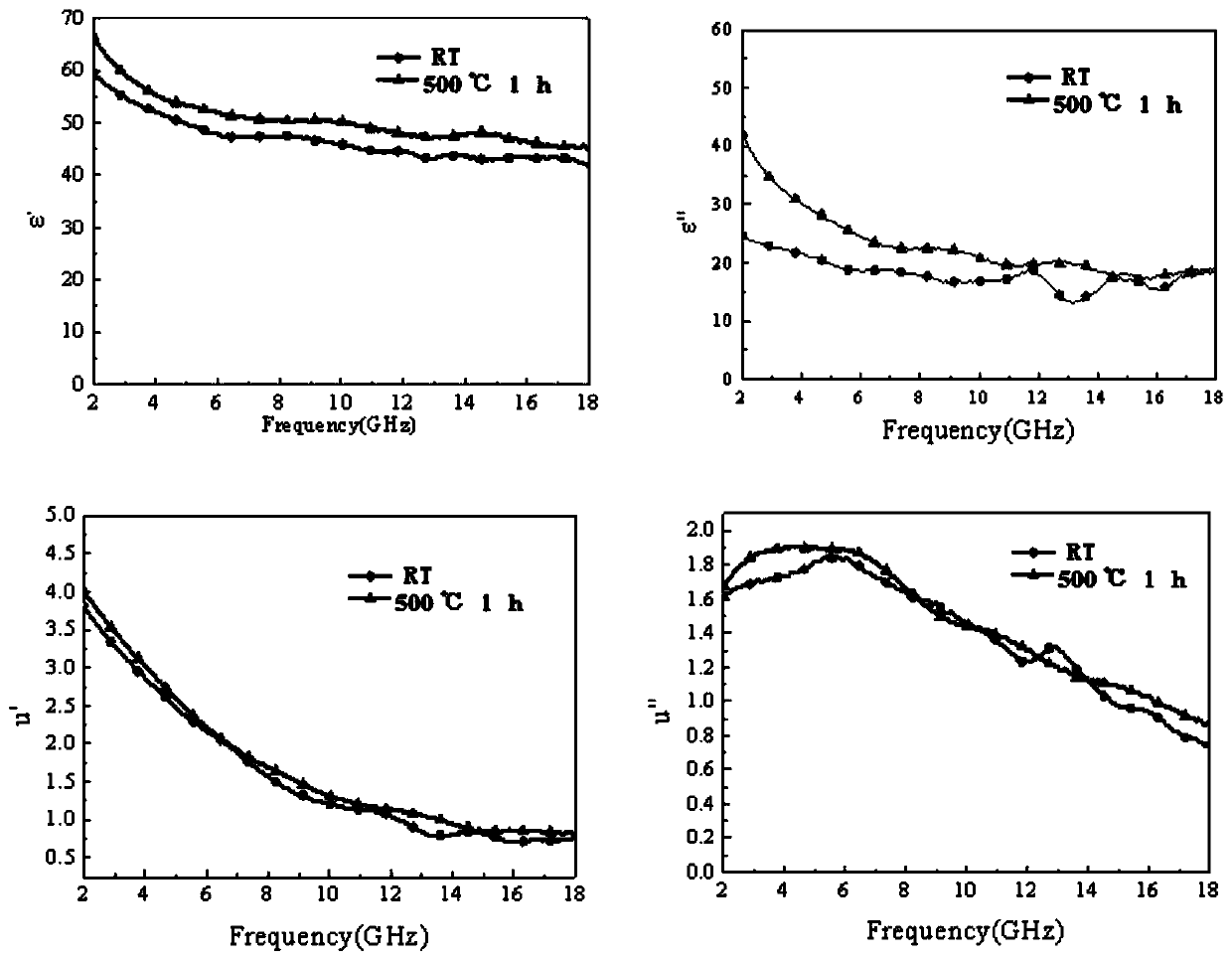

[0037] The Fe-based composite particle temperature-resistant absorbent of this embodiment is composed of 0.9 kg of carbonyl iron powder and 0.1 kg of Si powder; wherein: the carbonyl iron powder is a spherical particle with a smooth appearance and a particle size of 2-5 μm; The phase composition of the carbonyl iron powder is that the α iron phase is uniformly distributed; the particle size of the Si powder is 50-1000 mesh.

[0038] The above-mentioned Fe-based composite particle temperature-resistant absorbent in this embodiment is prepared by the following method, which specifically includes the following steps:

[0039] Accurately weigh 0.9kg of carbonyl iron powder and 0.1kg of Si powder, totaling 1kg; weigh 15kg of 10mm and 6mm stainless steel balls, the mass ratio of the two is 3:2. Put the above-mentioned raw materials into the ball mill tank, and after it is sealed, pass in high-purity Ar gas at a rate of 1.5L / min for 35min. After the ventilation is completed, tighten the ...

Embodiment 2

[0046] The Fe-based composite particle temperature-resistant absorbent of this embodiment is composed of 0.8 kg of carbonyl iron powder and 0.2 kg of Si powder; wherein: the carbonyl iron powder is a spherical particle with a smooth appearance and a particle size of 2-5 μm; The phase composition of the carbonyl iron powder is that the α iron phase is uniformly distributed; the particle size of the Si powder is 50-1000 mesh.

[0047] The above-mentioned Fe-based composite particle temperature-resistant absorbent in this embodiment is prepared by the following method, which specifically includes the following steps:

[0048] Accurately weigh 0.8kg of carbonyl iron powder and 0.2kg of Si powder totaling 1kg; weigh 20kg of 10mm and 6mm stainless steel balls, the mass ratio of the two is 3:2. Put the above-mentioned raw materials into the ball mill tank, and after it is sealed, pass in high-purity Ar gas at a rate of 1.5L / min for 35min. After the ventilation is completed, tighten the s...

Embodiment 3

[0055] The difference between this embodiment and embodiment 1 is that the Fe-based composite particle temperature-resistant absorbent of this embodiment is composed of 0.95 kg of carbonyl iron powder and 0.05 kg of Si powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com