A method for purifying polysilicon by using a liquid filter

A technology of polysilicon and filter screens, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth. It can solve the problems of not being able to meet solar energy, achieve stable grain size, and improve the effect of uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

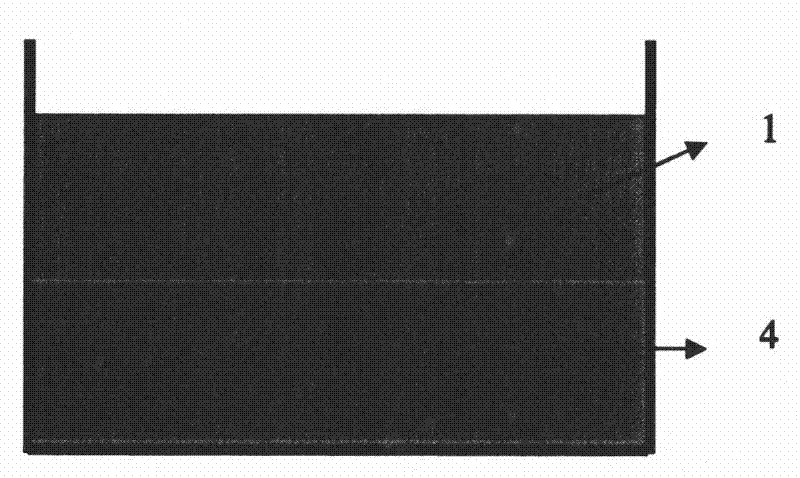

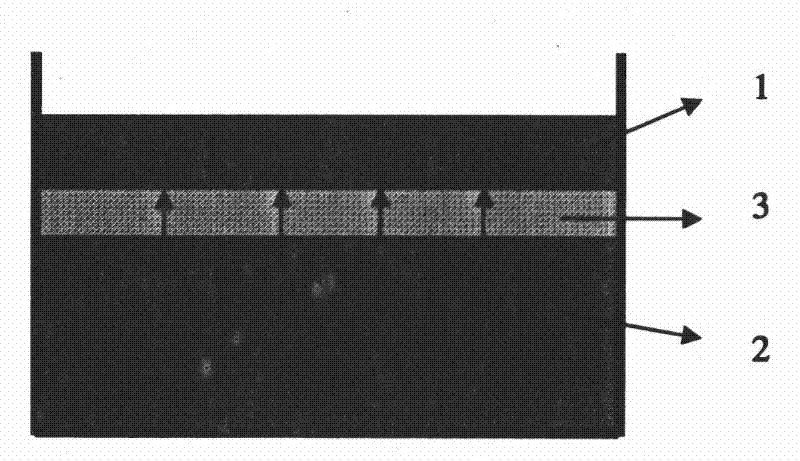

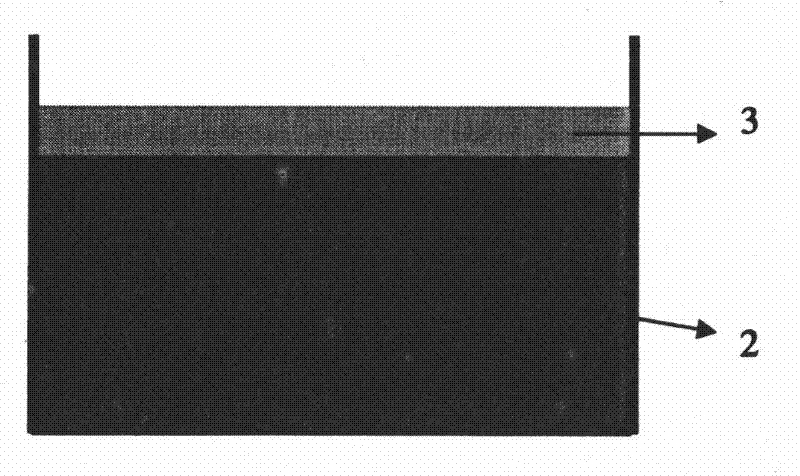

Embodiment 1

[0030] Put 140kg of 4-5N polycrystalline silicon into a quartz crucible, and put 60kg of Sn and Ga as the filter material at the same time, of which Sn is 55kg, Ga is 5kg, and vacuum pumped to 10 -3 After Pa, fill with argon, stop the diffusion pump to maintain a slight positive pressure in the furnace, turn on the control power supply, and the heater starts to heat until the mixture of silicon and filter material is completely melted at 1380 ° C, and the temperature is kept for 2 hours. Then turn on the temperature control to gradually cool the material in the crucible at a cooling rate of 0.2°C / h. During this process, silicon begins to crystallize, and the filter material slowly moves up. This process needs to maintain the temperature balance in the crucible. The temperature difference between the same horizontal plane in the crucible is kept at 0.2°C-0.5°C. The stability of the thermal field is the balance of the liquid filter. Guaranteed to move up slowly. After the tempe...

Embodiment 2

[0032] Put 160kg of 4-5N polysilicon into a quartz crucible, and put in a total of 40kg of Sn and Ga as the filter material at the same time, of which Sn is 39kg, Ga is 1kg, and vacuum pumped to 10 -3After Pa, fill with argon, stop the diffusion pump to maintain a slight positive pressure in the furnace, turn on the control power supply, and the heater starts to heat until the mixture of silicon and filter material is completely melted at 1400 ° C, and the temperature is kept for 3 hours. Then turn on the temperature control to gradually cool the material in the crucible at a cooling rate of 1°C / h. During this process, silicon begins to crystallize at this time, and the filter material slowly moves up. This process needs to maintain the temperature balance in the crucible. Guarantee that the net balance moves up slowly. After the temperature is cooled to 900°C, the temperature can be rapidly lowered, and the cooling rate is 15°C / h. After the crystallization process is over, ...

Embodiment 3

[0034] Put 170kg of 4-5N polysilicon into a quartz crucible, and put 30kg of filter material at the same time, including 28kg of Sn, 2kg of In, and vacuum to 10 -3 After Pa, fill it with helium, stop the diffusion pump to maintain a slight positive pressure in the furnace, turn on the control power supply, and the heater starts to heat until the mixture of silicon and filter material is completely melted at 1400 ° C, and the temperature is kept for 2.5 hours. Then turn on the temperature control to gradually cool the material in the crucible at a cooling rate of 5 °C / h. During this process, silicon begins to crystallize at this time, and the filter material slowly moves up. This process needs to maintain the temperature balance in the crucible. Guarantee that the net balance moves up slowly. After the temperature is cooled to 900°C, the temperature can be rapidly lowered, and the cooling rate is 20°C / h. After the crystallization process is over, cool down, take out the ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com