Rolling method for controlling grain size of heat-resistant 347H stainless steel medium plate

A technology of stainless steel and grain size, which is applied in metal rolling and other directions, can solve the problem that the heat-resistant 347H stainless steel plate grain size is difficult to control stably, and achieve the goal of extending the application range, reducing production costs, and solving technical bottlenecks Effect

Pending Publication Date: 2022-06-21

SHANXI TAIGANG STAINLESS STEEL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the shortcomings of the prior art, solve the technical problem that the grain size grade of the heat-resistant 347H stainless steel plate is difficult to stably control, and provide a rolling method for controlling the grain size of the heat-resistant 347H stainless steel plate method, heat-resistant stainless steel 347H obtains a uniform and stable structure and grain size grade by heating and controlling the rolling process parameters to meet the user's requirements for performance consistency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

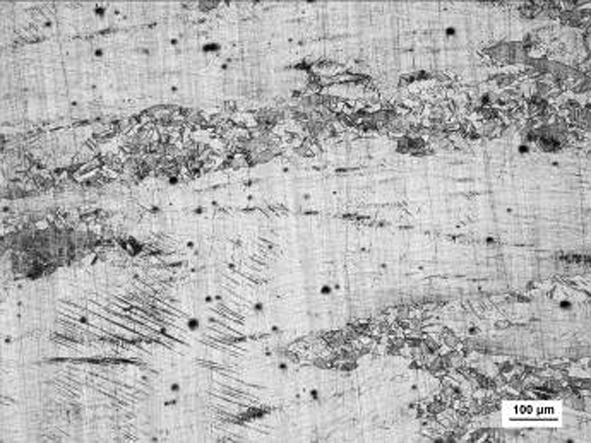

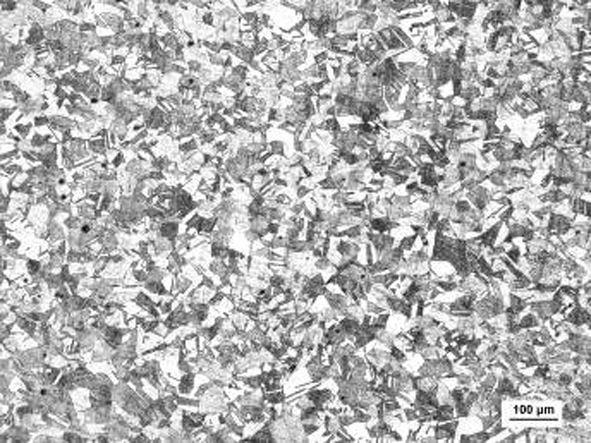

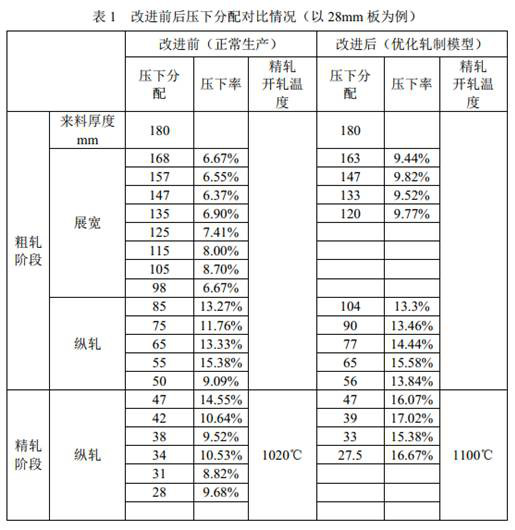

A rolling method for controlling the grain size of a heat-resistant 347H stainless steel medium plate belongs to the technical field of rolling, solves the technical problem that the grain size grade of the heat-resistant 347H stainless steel medium plate is difficult to stably control, and comprises the following steps: S1, blank heating: uniformly heating a blank at a heating speed of 11min / 10mm under the conditions that the hearth pressure is 20-30Pa and the exhaust gas opening degree is 20%; s2, rough rolling is conducted through a reversible rolling mill, wherein the reduction rate in the broadening process is 9%-10%; the reduction rate in the longitudinal rolling process is controlled to be 13-15%; and S3, finish rolling is conducted through a reversible rolling mill, wherein the reduction rate is 15-18%, and the heat-resistant 347H stainless steel medium plate is prepared. On the premise that the blank is uniformly heated, the initial grain size of 347H is stabilized in a certain level interval range by adopting a rolling mode of high pressure under a high temperature condition in the rolling procedure, so that consistent and uniform grains are formed on the core part and the surface of the middle plate.

Description

technical field [0001] The invention belongs to the technical field of rolling, and in particular relates to a rolling method for controlling the grain size of heat-resistant 347H stainless steel plates. Background technique [0002] The heat-resistant 347H stainless steel plate has been ordered without guaranteeing the grain size, but in order to obtain better performance indicators and meet the individual needs of users, it is applied to more high-end fields and stabilizes the grain size of 347H Gradually become market demand. In order to continue to lead the market and meet the needs of high-end fields and users, it is imminent to stably control the grain size grade of 347H. Contents of the invention [0003] The purpose of the present invention is to overcome the shortcomings of the prior art, solve the technical problem that the grain size grade of the heat-resistant 347H stainless steel plate is difficult to stably control, and provide a rolling method for controlli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21B3/02C21D8/02

CPCB21B3/02C21D8/0221C21D8/0205

Inventor 陶华丁晨晖杨明永谈津贾超君郭保兵宋志飞

Owner SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com