Built-in water curtain wall in dust collection apparatus

A technology for dust recovery and water curtain wall, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc. It can solve the problems of large loss of absorption liquid, low discharge dust compliance rate, environmental pollution, etc., and achieve delayed residence time. , Improve the absorption effect, reduce the effect of particle temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

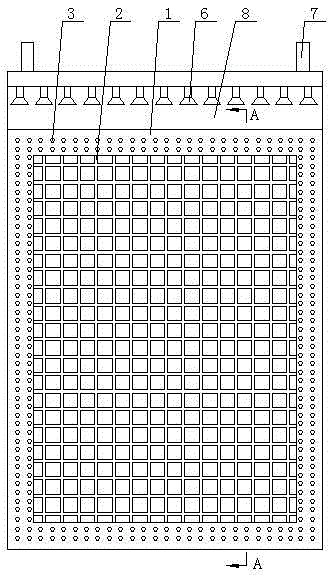

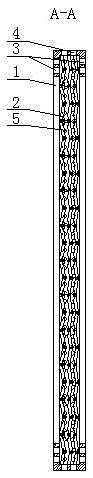

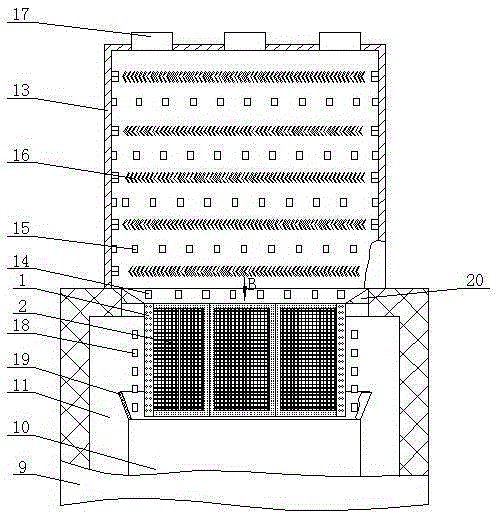

[0007] figure 1 The shown embodiment is one of the structures used in connection with the water curtain wall and the liquid spraying structure of the present invention, image 3 The illustrated embodiment is the second structure in which the water curtain wall of the present invention is used in connection with structures such as spray liquid.

[0008] The water curtain wall installed in the dust recovery device according to the present invention includes a metal frame 1, the metal frame 1 is rectangular, and a wavy metal mesh 2 is installed in the metal frame 1, and the wavy metal mesh 2 is formed by overlapping 7-16 layers Certain thickness, on the upper, lower, left and right frames and upper, lower, left and right end faces of the metal frame 1 are all provided with some water inlet holes, and each water inlet holes are evenly distributed. The water curtain wall of the present invention can be installed in dust recovery devices of various structures. It can make the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com