Spraying and granulating separation column with jacket cooling system on taper section

A technology of spray granulation and jacket cooling, which is applied in the direction of liquid droplet granulation, solidification/crushing processing of tar asphalt/petroleum asphalt/natural asphalt, etc., which can solve the problems of asphalt particle separation and output difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

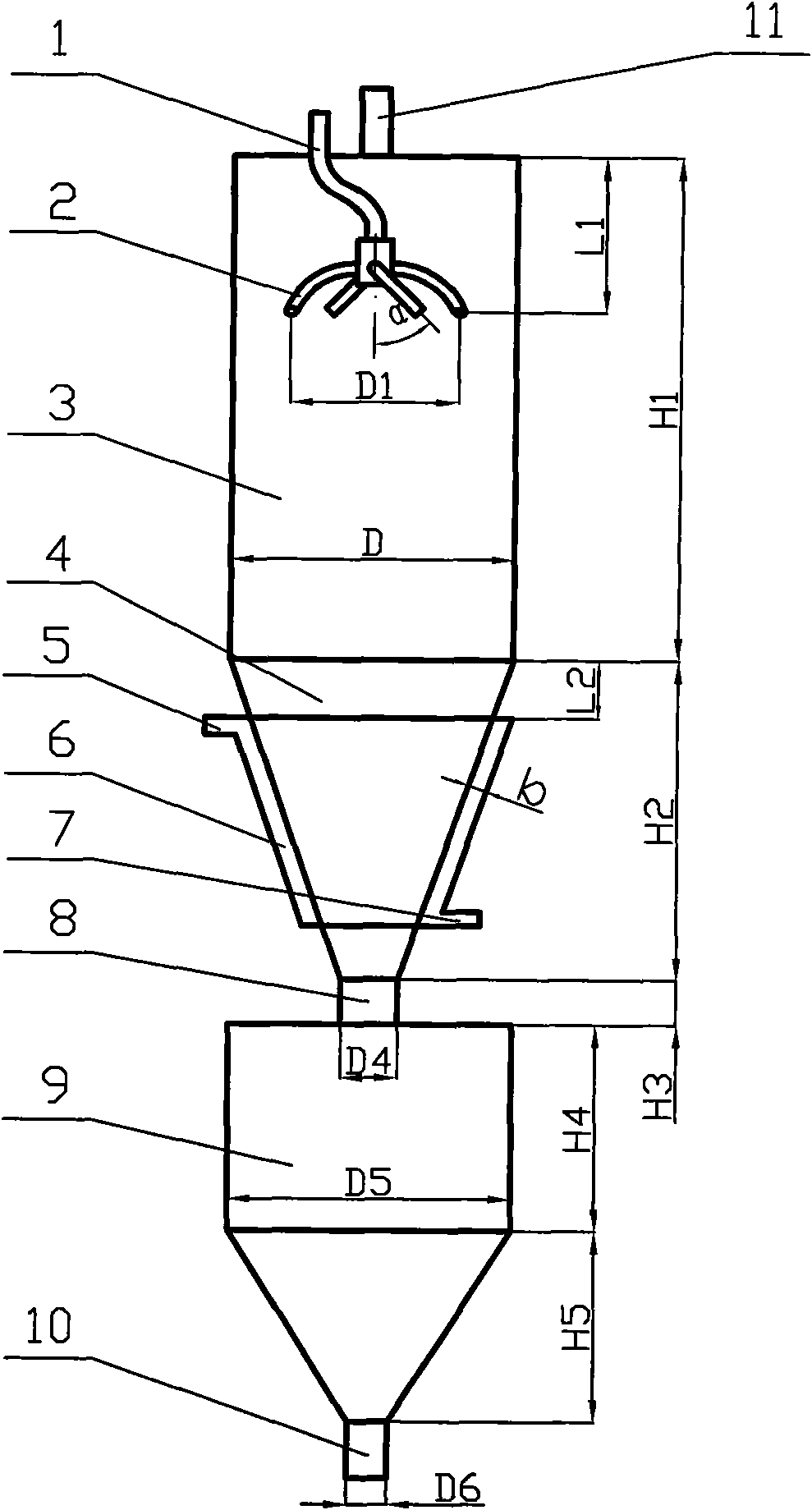

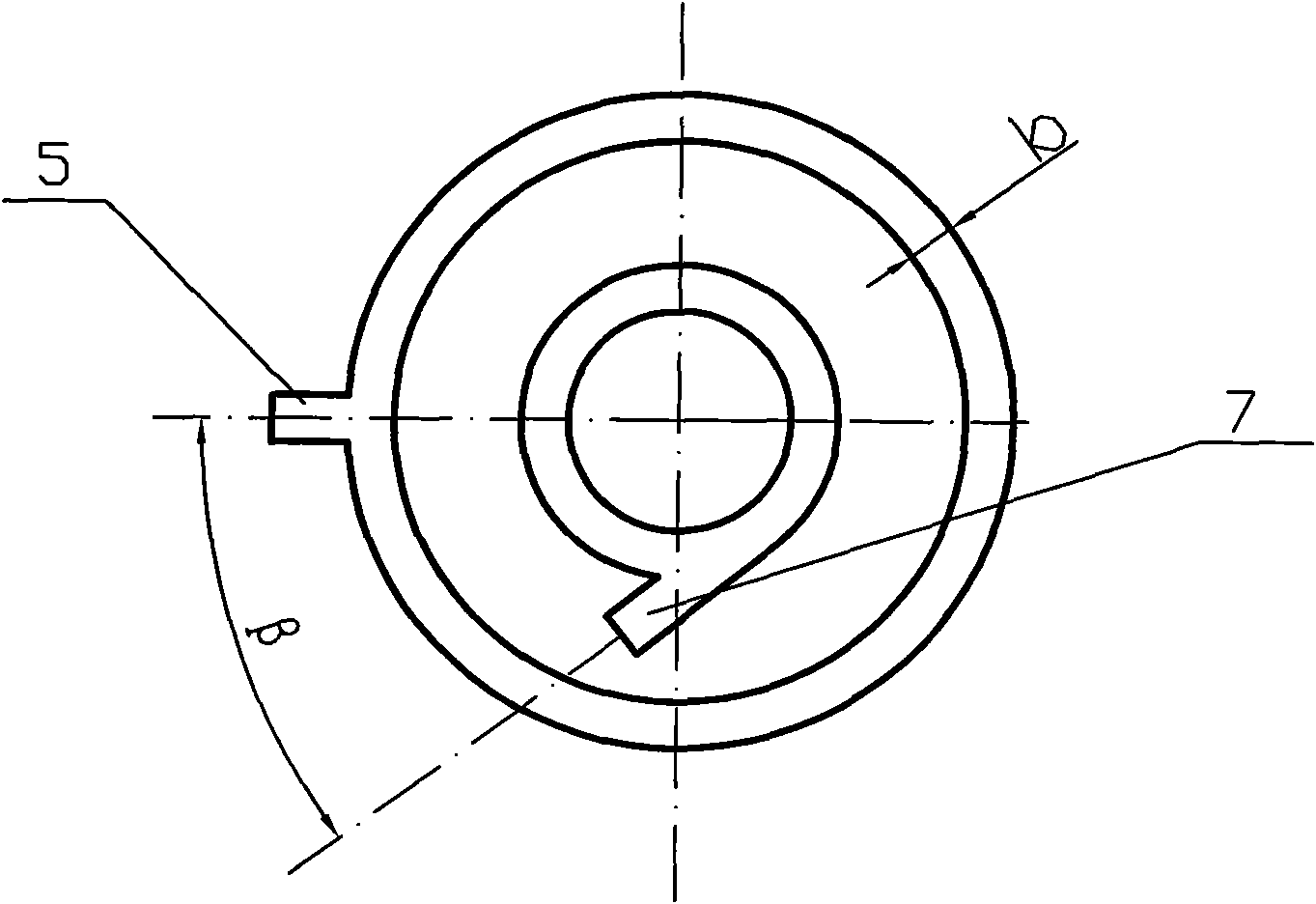

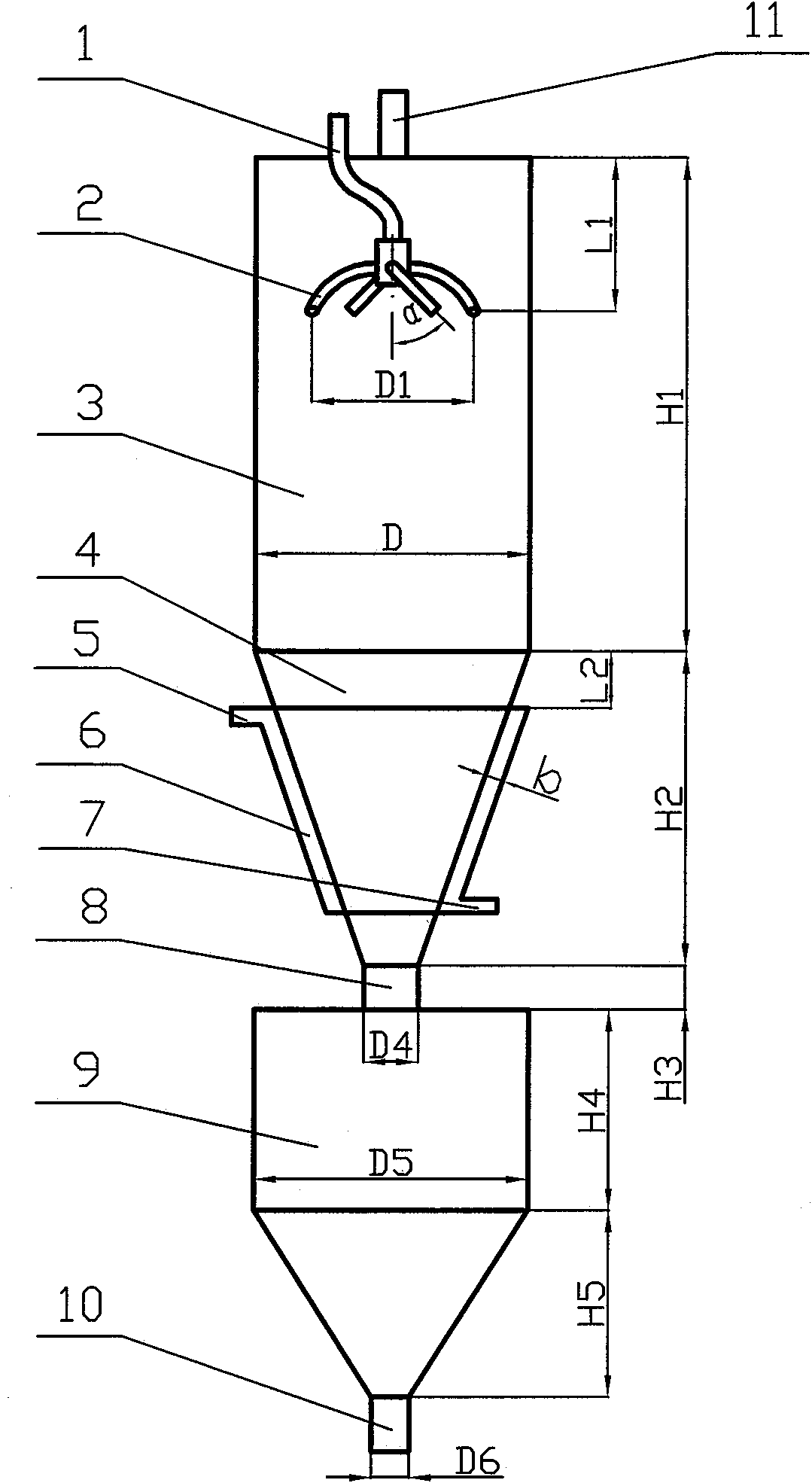

[0014] The working process of the spray granulation separation tower of the present invention will be described below in conjunction with the accompanying drawings.

[0015] The use process of the spray granulation separation tower of the present invention, for example, can be that the mixture of the high temperature and high pressure liquid phase solvent and the asphalt residue enters the spray granulation nozzle system (2) through the mixture feed pipe (1), and the mixture material is sprayed by each nozzle. Into the prilling tower, due to the pressure drop, the liquid phase solvent flash vaporizes, and the bitumen becomes solid particles. While completing the granulation process, through the arrangement of nozzles, a downward rotary motion is formed in the separation and settling section (3) of the granulation tower. Under the action of centrifugal force, the gas phase solvent is separated from the solid particles, and the solid particles are separated to the wall, slide do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com