Molten slag dry granulation and waste heat recovery system

A waste heat recovery system and dry granulation technology, applied in the field of metallurgical energy saving, can solve the problems of high temperature resistance requirements of slag particle conveying equipment, high temperature of slag particles, hardening and agglomeration, etc., to reduce the temperature of slag particles, reduce The effect of high temperature resistance and lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

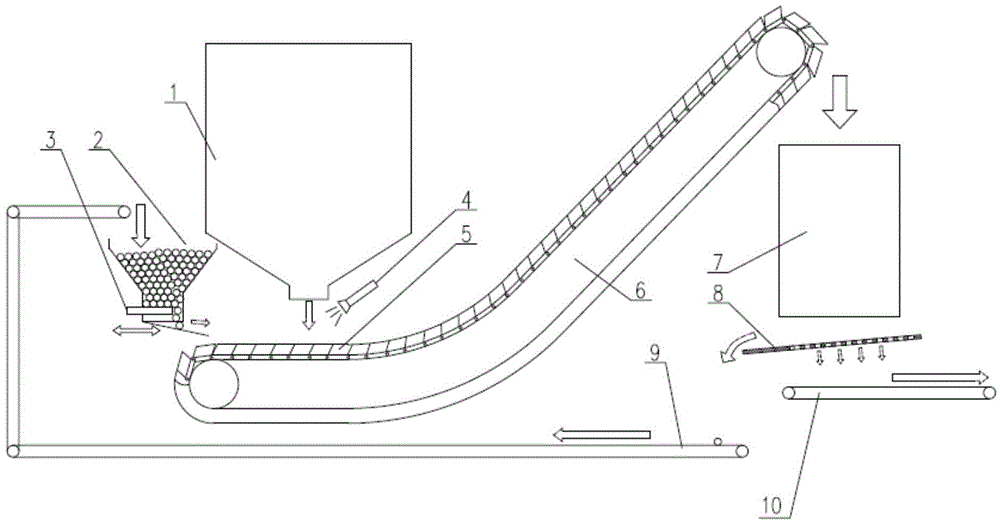

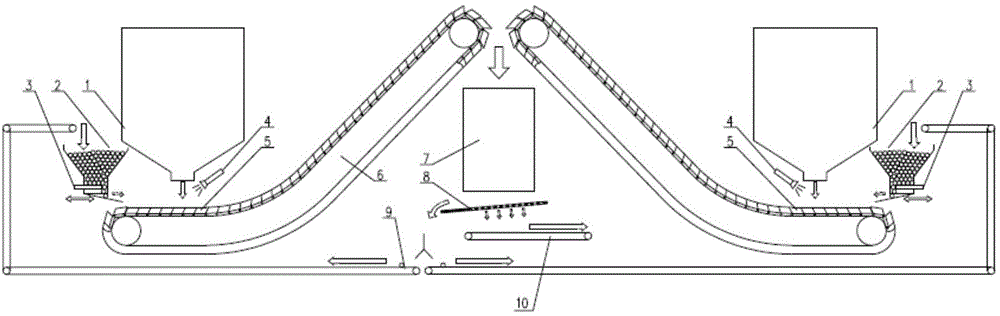

[0022] Such as figure 2 As shown, the two dry granulation units 1 transport slag particles to the same waste heat recovery unit 7 through the chain bucket conveyor 6 respectively. The dry granulation unit 1 and the waste heat recovery unit 7 are located at the same level, and the chain bucket conveyor 6. Convey horizontally and then upwardly, with an inclination angle of 20 to 30 degrees; the cold material bin 2 is equipped with low-temperature slag particles with a large particle size, and the high-temperature slag is mixed with the high-temperature slag at the outlet of the granulation unit 1 through the flow adjustment device 3 at a suitable flow rate. The slag particles impact and mix with each other, and fall into the hopper 5 of the chain bucket conveyor 6; after the waste heat recovery unit 7, a screening device 8 is used to separate the slag particles with a diameter of 3 to 5 mm, and the slag particles with a diameter of 3 to 5 mm are separated through the cold materi...

Embodiment 2

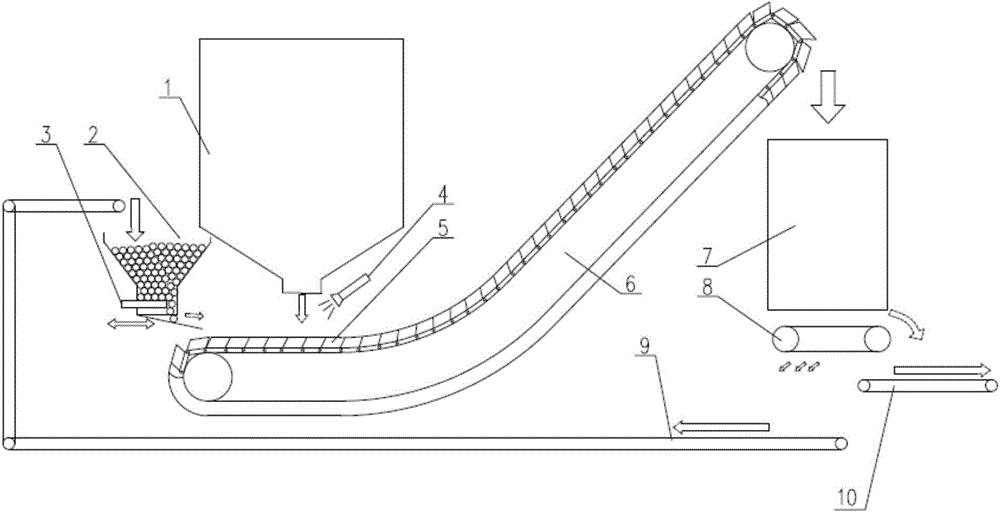

[0024] Such as image 3 As shown, the dry granulation unit 1 and the waste heat recovery unit 7 are located on the same horizontal plane, connected by the chain bucket conveyor 6, and the chain bucket conveyor 6 is first conveyed horizontally and then inclined upward, with an inclination angle of 20-30 degrees; cold material The bin 2 is equipped with steel balls, which fall into the hopper 5 of the chain bucket conveyor 6 at a suitable flow rate through the flow regulating device 3, and spread on the bottom of the hopper 5; when the temperature measuring device 4 measures the temperature of the slag particles 11 higher than the set When the value is fixed, each hopper is filled with multi-layer steel balls 12, and when the measured temperature is lower than the set value, the amount of steel balls loaded in the hopper is reduced; the mixture of steel balls and slag particles recovers heat through the waste heat recovery unit 7 Finally, when the temperature drops below 150°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com