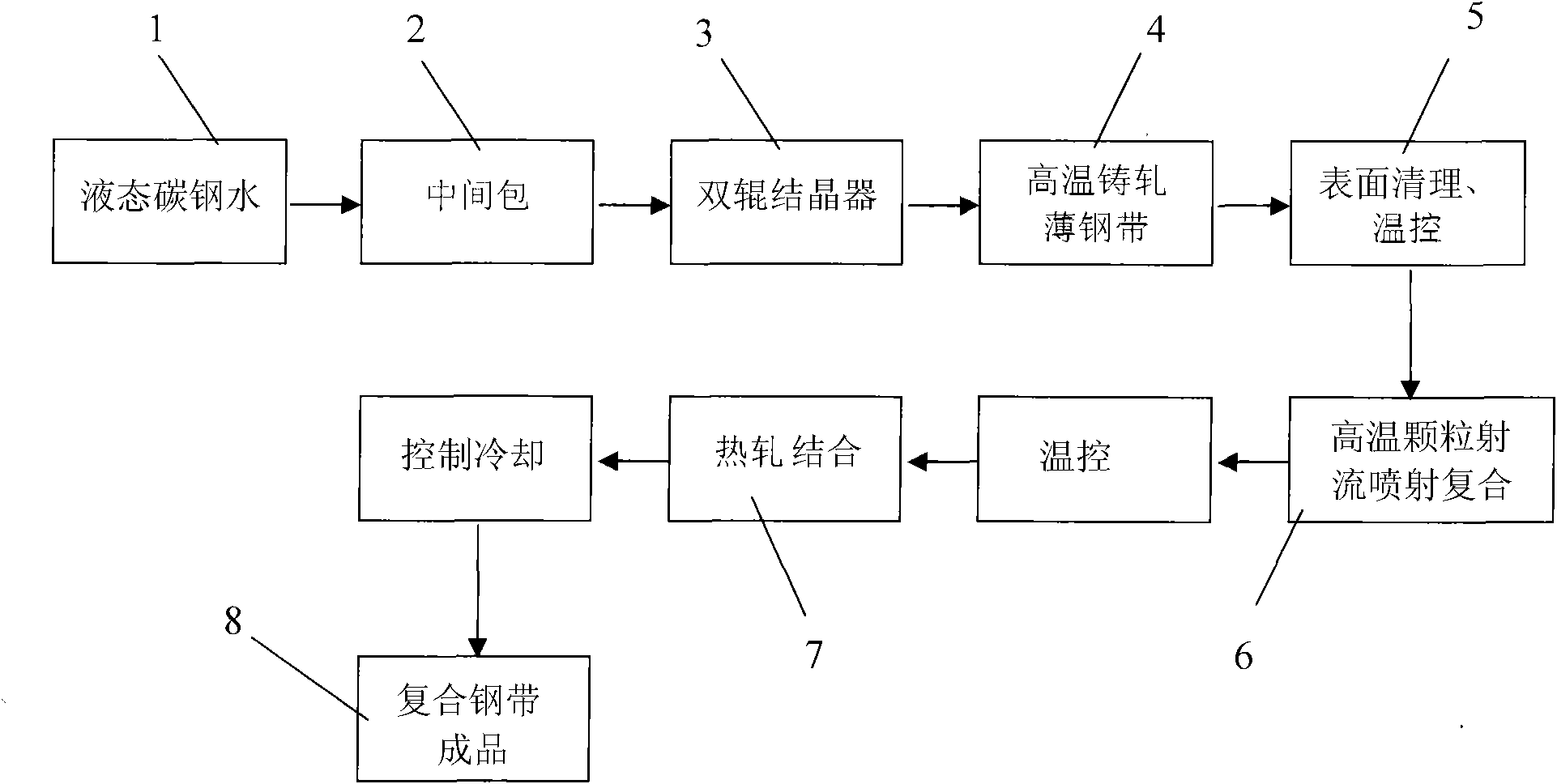

Method for producing composite steel plate by strip continuous casting and tandem rolling

A technology of continuous casting, continuous rolling, and clad steel plates, which is applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of immature technology, difficult to flexibly control stainless steel and carbon steel, etc., and achieve high production efficiency. , good deformation ability, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Heat a 2mm thick carbon steel plate to 1400°C in an inert gas shielded furnace and keep it warm for 5 minutes. The 304 stainless steel particle jet is introduced, the particle jet velocity is 650m / s, the average particle size is 65 microns, the maximum particle size is 100 microns, and the temperature is 550°C. A 200 micron stainless steel layer was formed on both surfaces. The carrying protective gas temperature is nitrogen at 650°C. Cool down to 950°C with the furnace, and roll down 20% in a single pass. 200°C insulation. The actual thickness of the obtained composite steel plate is 1.9mm, and the surface composition is 304 stainless steel.

Embodiment 2

[0045] Heat the 5mm thick IF steel plate in an inert gas shielded furnace to 1100°C and keep it warm for 15min. The 410 stainless steel particle jet is introduced, the particle jet velocity is 710m / s, the average particle size is 55 microns, the maximum particle size is 75 microns, and the temperature is 650°C. A stainless steel layer with a thickness of about 500 microns on each of the double surfaces is formed. The carrying protective gas temperature is nitrogen at 800°C. Cool down to 1000°C with the furnace, and roll down 30% in a single pass. 450°C heat preservation. The actual thickness of the obtained composite steel plate is 4.5 mm, the surface composition is 410 stainless steel, and the nickel content is reduced to a certain extent.

Embodiment 3

[0047] Heat a 3mm thick carbon steel plate to 1250°C in an inert gas shielded furnace and keep it warm for 10 minutes. The 2507 duplex stainless steel particle jet is introduced, the particle jet velocity is 680m / s, the average particle size is 45 microns, the maximum particle size is 80 microns, and the temperature is 600°C. A stainless steel layer with a thickness of about 400 microns on each of the double surfaces is formed. The carrying protective gas temperature is nitrogen at 800°C. Cool down to 890°C with the furnace, and roll down 15% in a single pass. Direct water quenching. The actual thickness of the obtained composite steel plate is 3.5mm, and the surface composition is 2507 stainless steel, which contains a certain amount of martensite structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com