Gas delivery pipeline drag reducer and preparation thereof

A technology for conveying pipelines and drag reducers, which is applied in the field of polymer compound compositions and pipeline systems, can solve problems such as limited drag reduction effects, and achieve the effects of convenient operation, mild reaction conditions, and reduced turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 10 parts of pyridine and 8 parts of diisopropylamine into a three-necked flask, stir for 15 minutes, and add 10 parts of formaldehyde solution to the mixed solution at a reaction temperature of 35°C for 1 hour to react, and add 12 parts of benzene to the above solution. Add formic acid, dropwise add 60-75ml of deionized water at the same time, stir and react for 3-4 hours, remove water and purify to obtain the product.

Embodiment 2

[0024] Add 10 parts of pyridine and 10 parts of diisopropylamine into a three-necked flask, stir for 15 minutes, and add 15 parts of formaldehyde solution to the mixed solution at a reaction temperature of 40°C for 1 hour to react, and add 15 parts of benzene to the above solution. Add formic acid, dropwise add 60-75ml of deionized water at the same time, stir and react for 3-4 hours, remove water and purify to obtain the product.

Embodiment 3

[0026] Add 10 parts of pyridine and 15 parts of diisopropylamine into a three-necked flask, stir for 15 minutes, and add 15 parts of formaldehyde solution to the mixed solution at a reaction temperature of 36°C for 1 hour to react, and add 15 parts of benzene to the above solution. Add formic acid, dropwise add 60-75ml of deionized water at the same time, stir and react for 3-4 hours, remove water and purify to obtain the product.

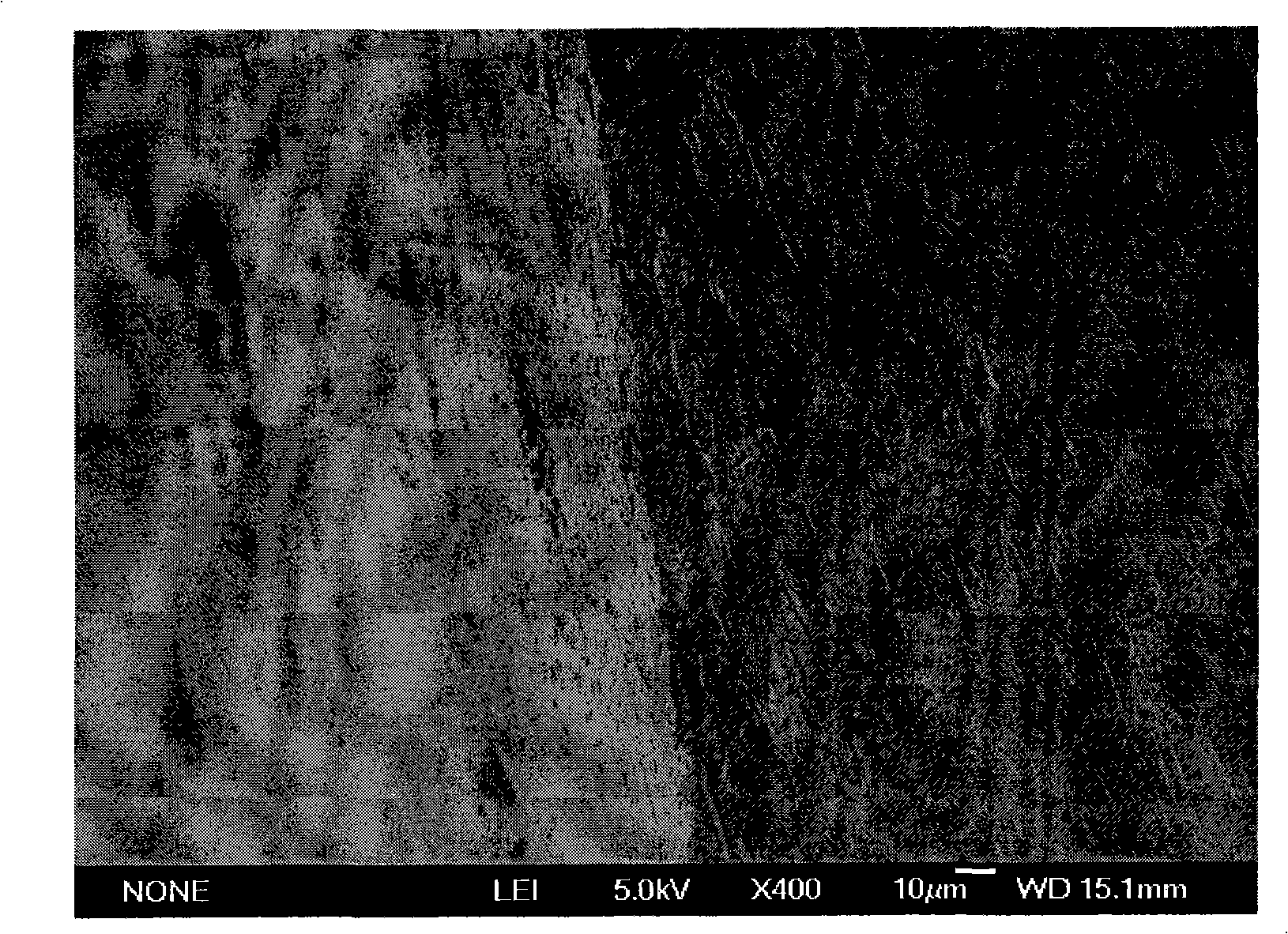

[0027] The product of above-mentioned embodiment is carried out film-forming process and electron microscope analysis, and the result is as follows: Figure 1 ~ Figure 4 shown.

[0028] A certain amount of this product is dissolved in an appropriate amount of absolute ethanol, the steel sheet is processed (oil removal, rust removal, and polished with metallographic paper), and the above solution is sprayed on the processed steel sheet with a spray device. Microscopic analysis was performed on a JEDL JSM-6700F scanning electron microscope.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com