Intervertebral disc implant

a technology of intervertebral discs and implants, which is applied in the field of intervertebral disc implants, can solve the problems of compromising the normal interaction between the disc and adjacent vertebrae, affecting the patient's life, and affecting the patient's quality of life,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

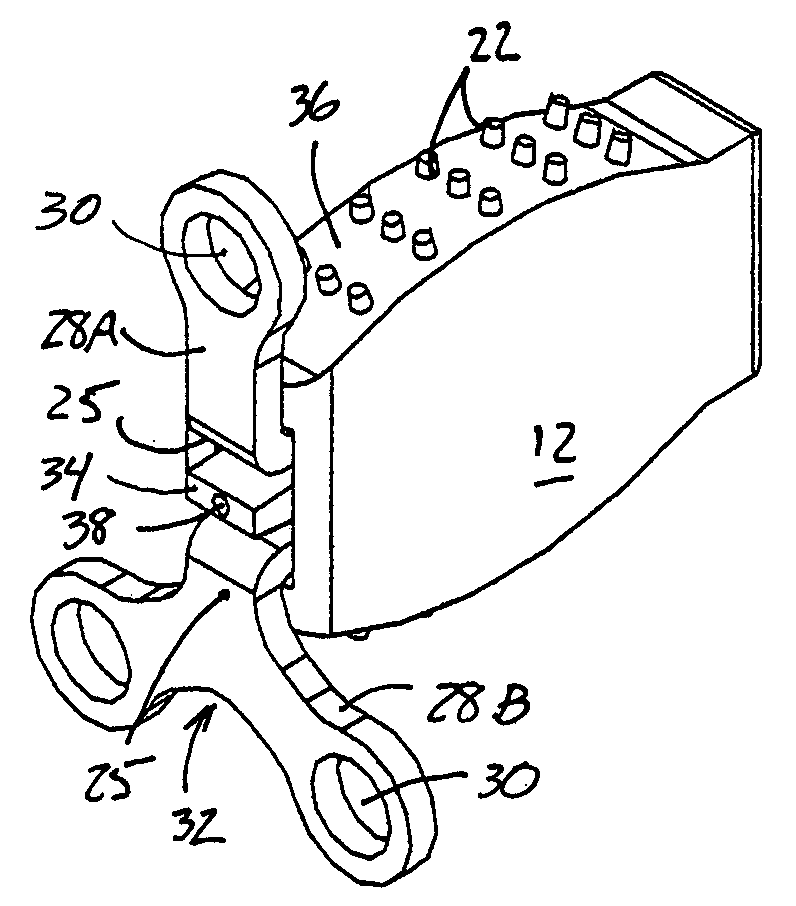

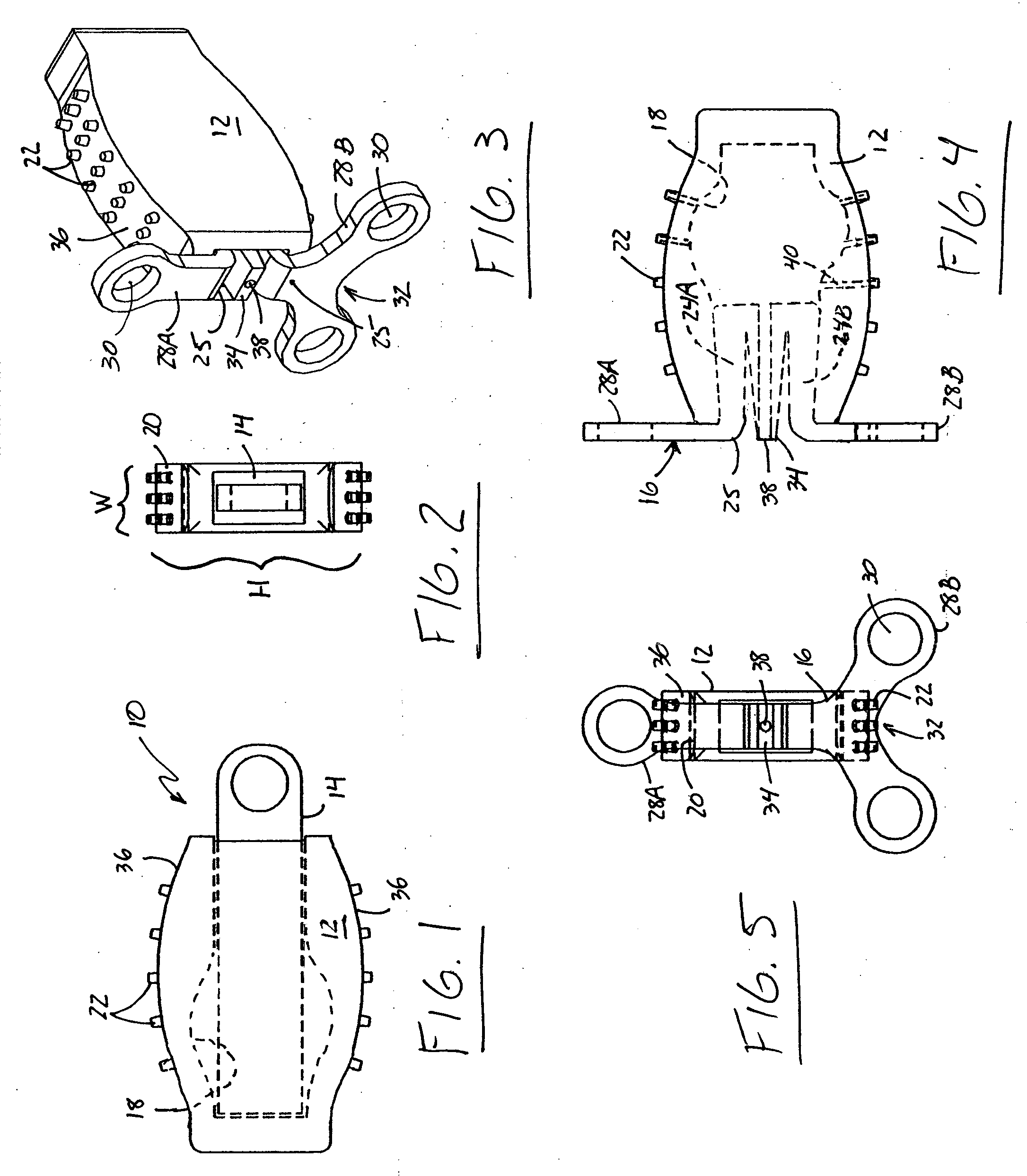

[0023] In more detail, FIG. 1 shows a presently preferred embodiment of an intervertebral disc implant constructed in accordance with the teachings of the present invention at reference numeral 10. Disc implant 10 is comprised of three components, each described in more detail below, implant body 12, key 14, and frame 16. Body 12 is preferably molded from a resilient, polymeric material. Although not limited to these materials, in the preferred embodiment, body 12 is molded from a biocompatible, viscoelastic polymer such as silicone, a urethane such as a polycarbonate urethane, or a polyurethane. As shown in FIGS. 1, 2, and 3, the body 12 is molded with a profile that approximates the shape of the normal intervertebral disc space with a height H greater than the width W (see FIG. 2); the top and bottom surfaces 36 of body 12 are arched so that the height of body 12 is greater in the center than at its ends. This shape of body 12 is referred to as being biconvex, e.g., both the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com