General Hopkinson bar device for compression load and stretching load

A Hopkinson rod and rod technology, used in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc., can solve problems that have not yet been found, and achieve the effect of convenient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

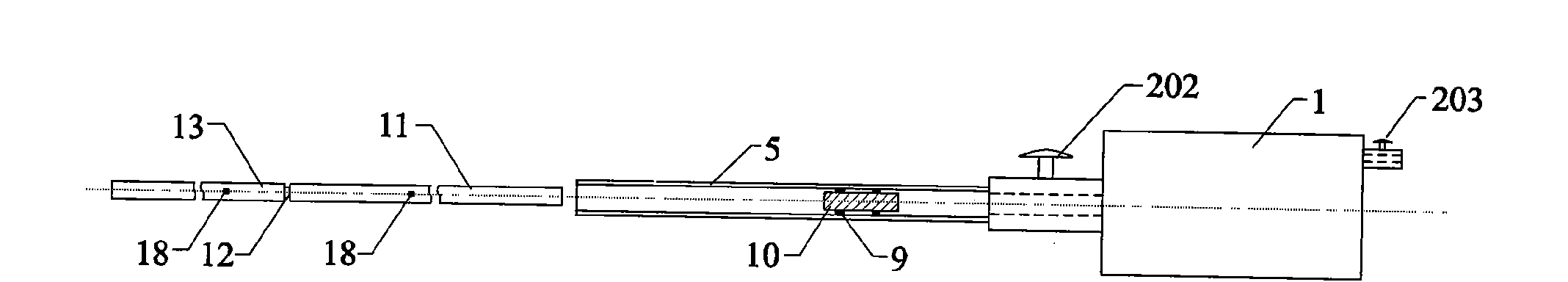

[0019] figure 1 The usual Hopkinson strut setup is given. Common Hopkinson pressure bar device is made up of high-pressure gas tank 1, the second air outlet control valve 202, air intake control valve 203, gun barrel 5, bullet rest 9, cylindrical bullet 10, compression incident rod 11, compression transmission rod 13 and The strain gauge 18 is composed. Intake control valve 203 is installed on the top of the right side end face of the high-pressure gas tank, and the second outlet control valve 202 is installed on the left side end face center of the high-pressure gas tank. Cylindrical bullet 10 is placed in gun barrel 5 by the cooperation of bullet holder 9. A strain gauge 18 is glued to the center of the rod wall of the compression incident rod 11 and the compression transmission rod 13 . Compression sample 12 is sandwiched between compression incidence rod 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com