Impact of copper and carbon on mechanical properties of iron-carbon-copper alloys for powder metal forging applications

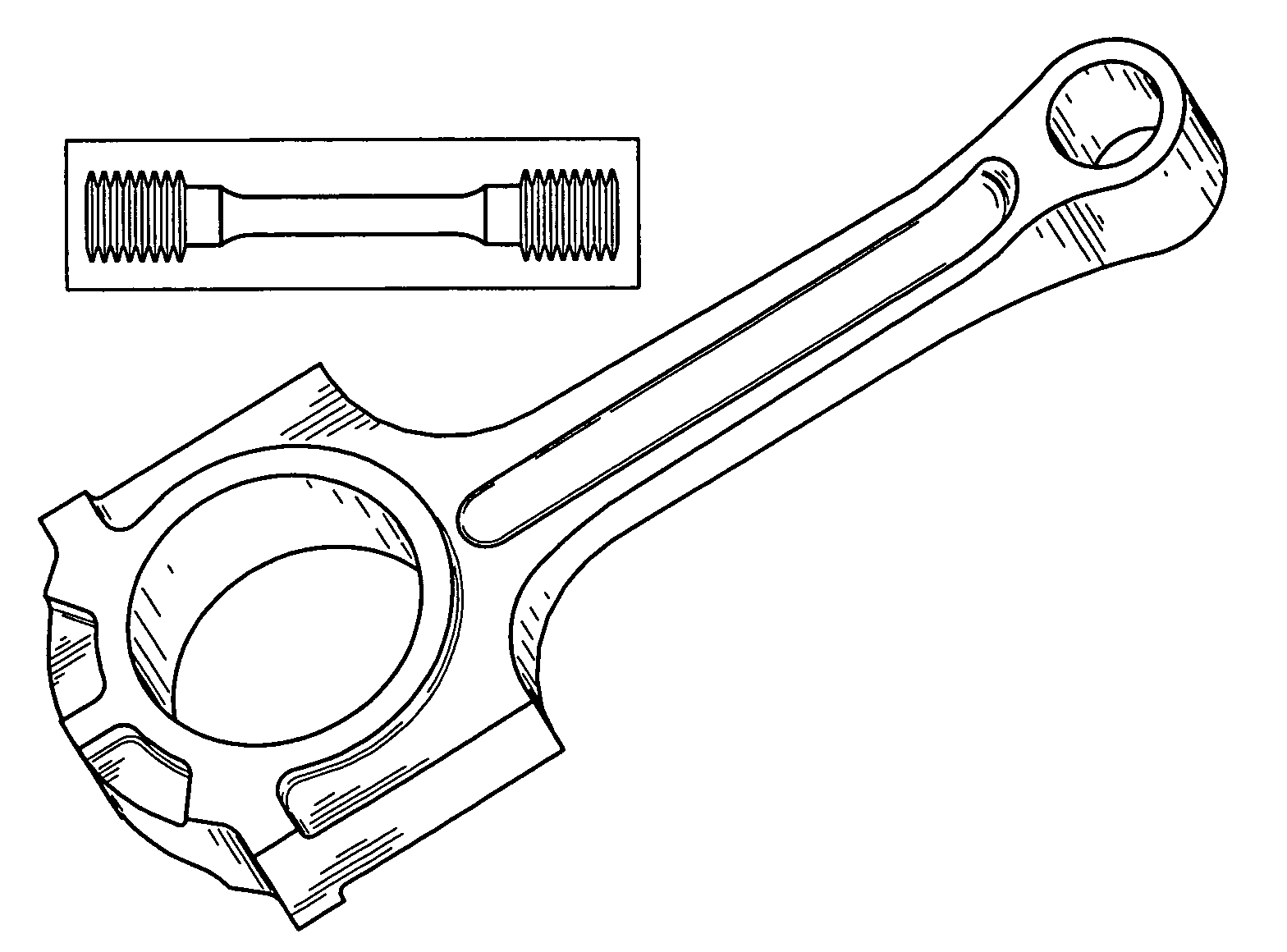

a technology of iron-carbon-copper alloys and mechanical properties, applied in the direction of mechanical equipment, shafts and bearings, connecting rods, etc., can solve the problems of contradictory and incomplete findings of these reports, and the use of higher copper content in wrought materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] While the present invention is described with reference to the preferred embodiment, it should be clear that the present invention should not be limited to this embodiment. Therefore, the description of the preferred embodiment herein is illustrative of the present invention and should not limit the scope of the invention as claimed.

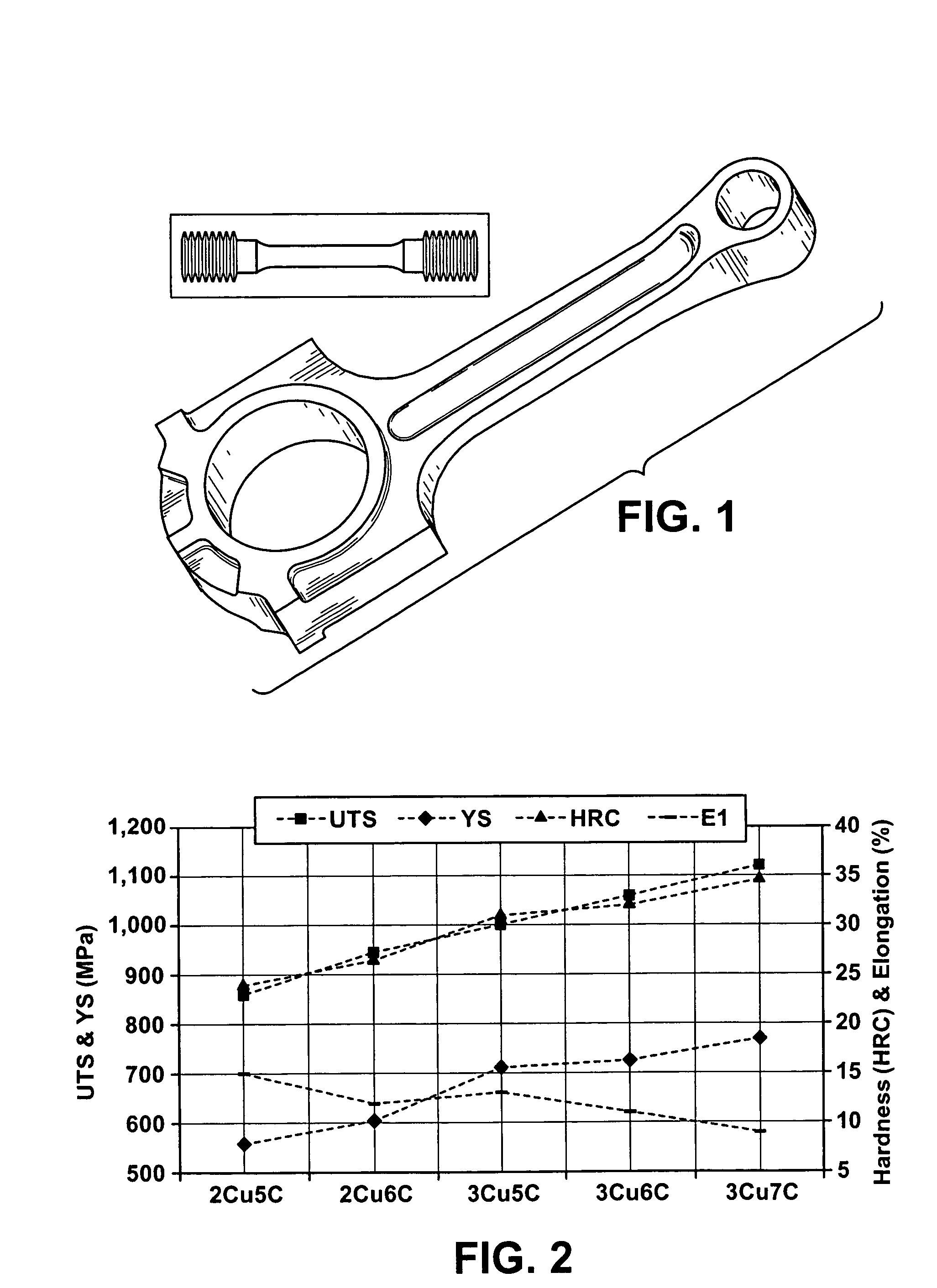

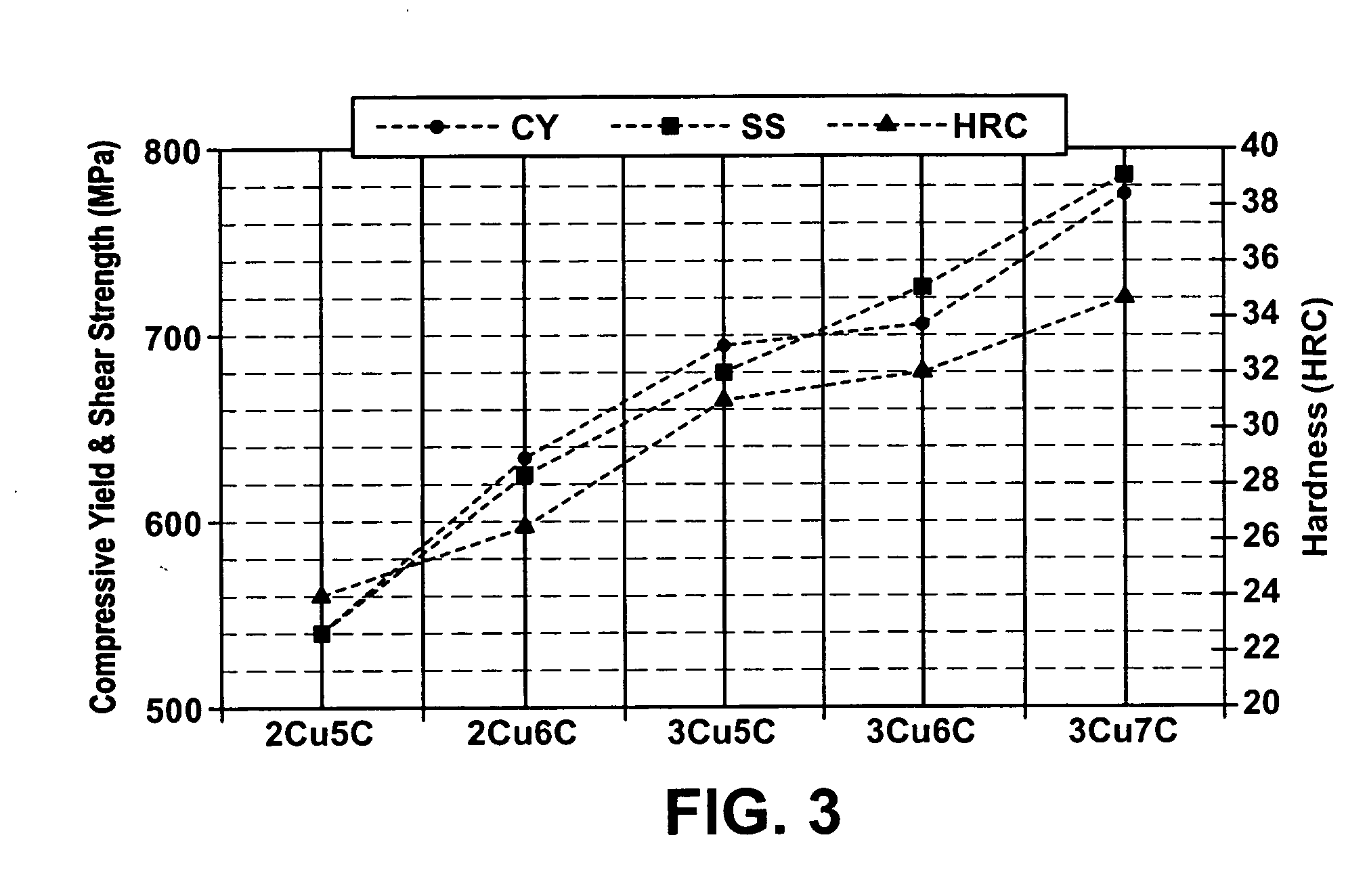

[0029] The effect of copper contents (from 2% to 4%) on iron-based powder metal sintered-forged materials was studied. This study also included the previously developed HS150™ in its results. The conclusion was that mechanical properties peak at the level of approximately 3% copper under processing conditions considered. Graphite contents of approximately 0.58%, 0.68%, and 0.78% were admixed, along with approximately 2.0% and 3.0% copper, and approximately 0.32% manganese sulfide (MnS), into an atomized ferrous base powder. Static and dynamic tests were carried out on specimens machined out of fully dense (hot forged) components and pucks. Correl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com