Reversing valve and combustion engine with the reversing valve

A technology of internal combustion engine and reversing valve, which is applied in the direction of engine components, engine control, machine/engine, etc., to achieve the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

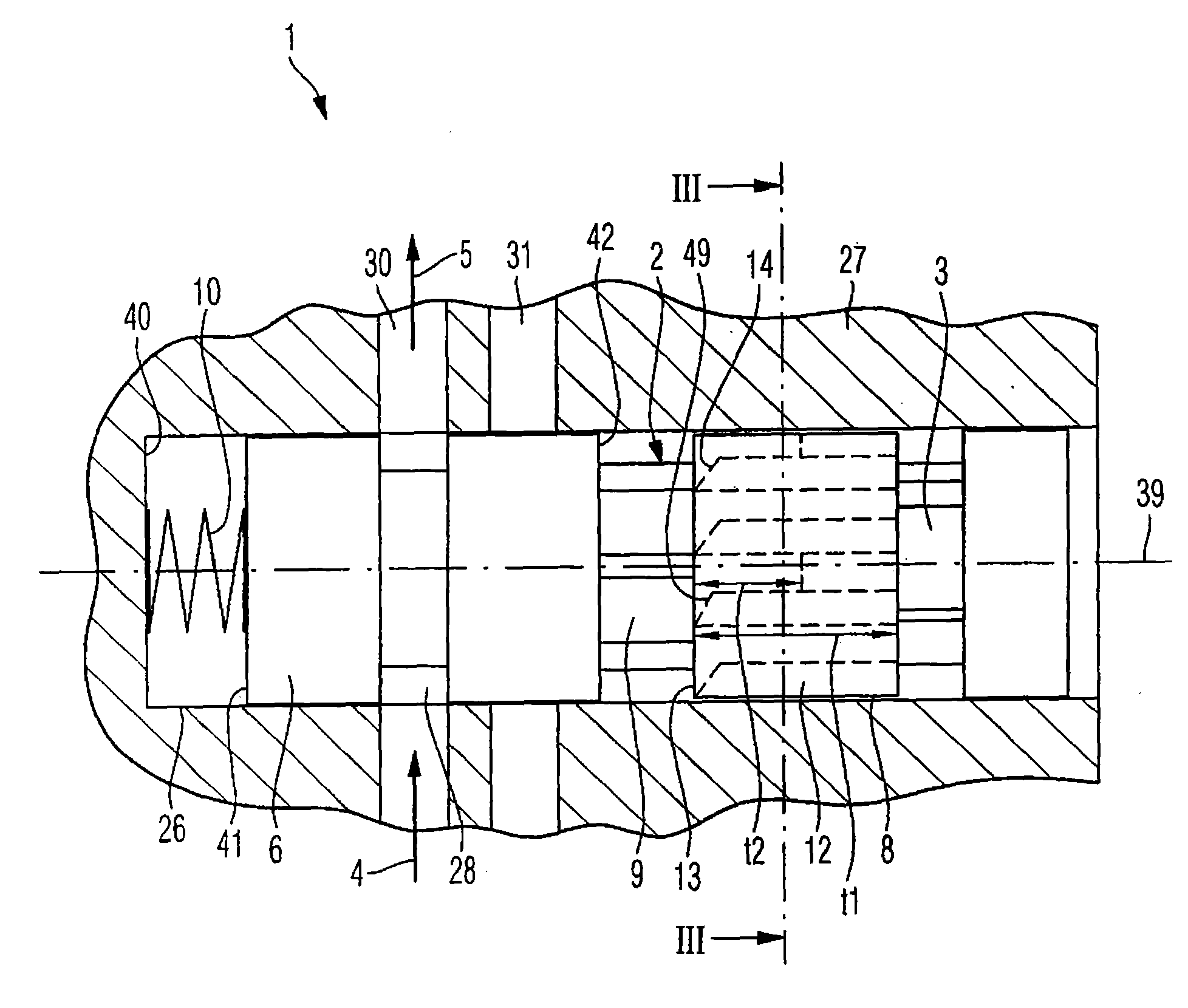

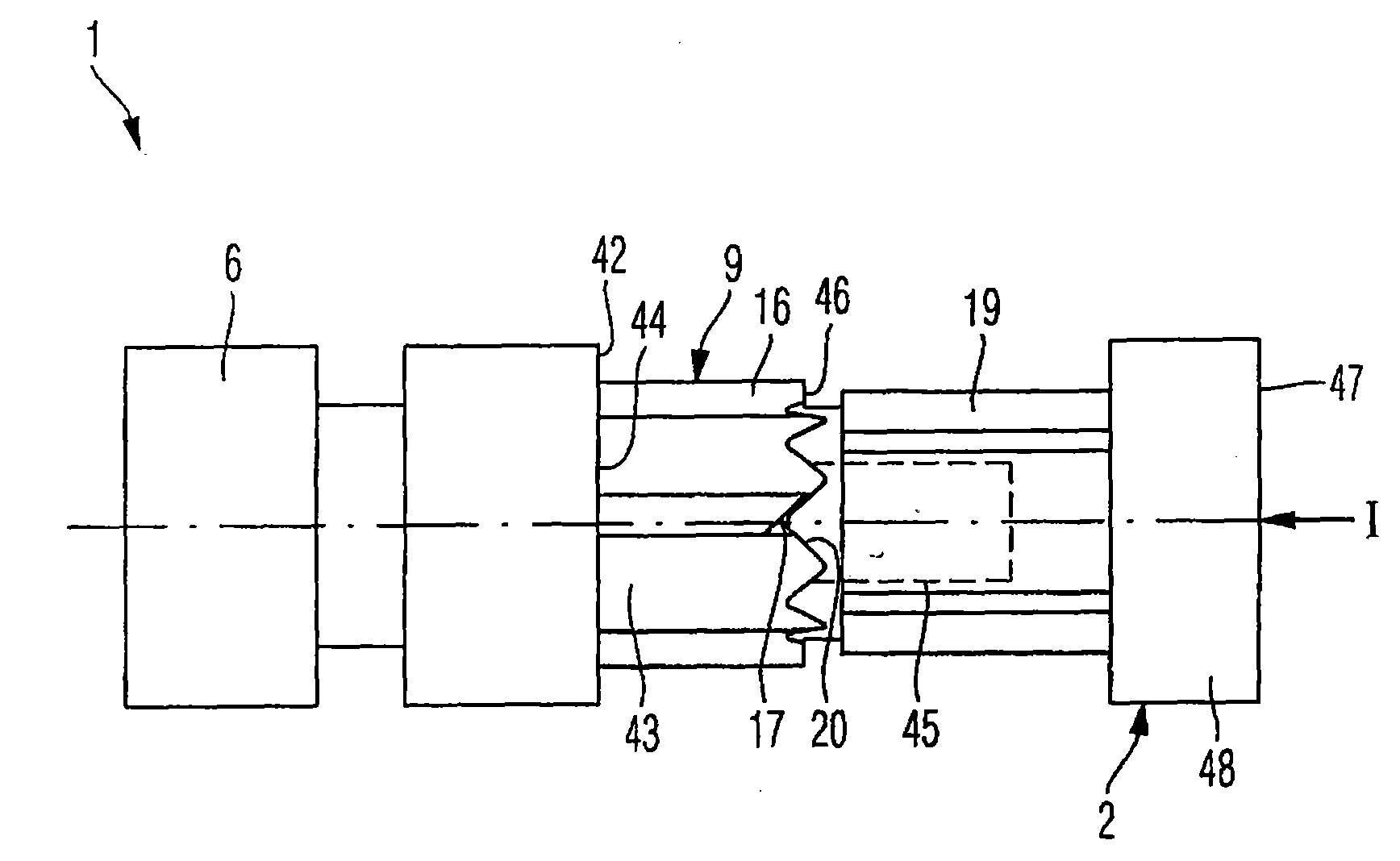

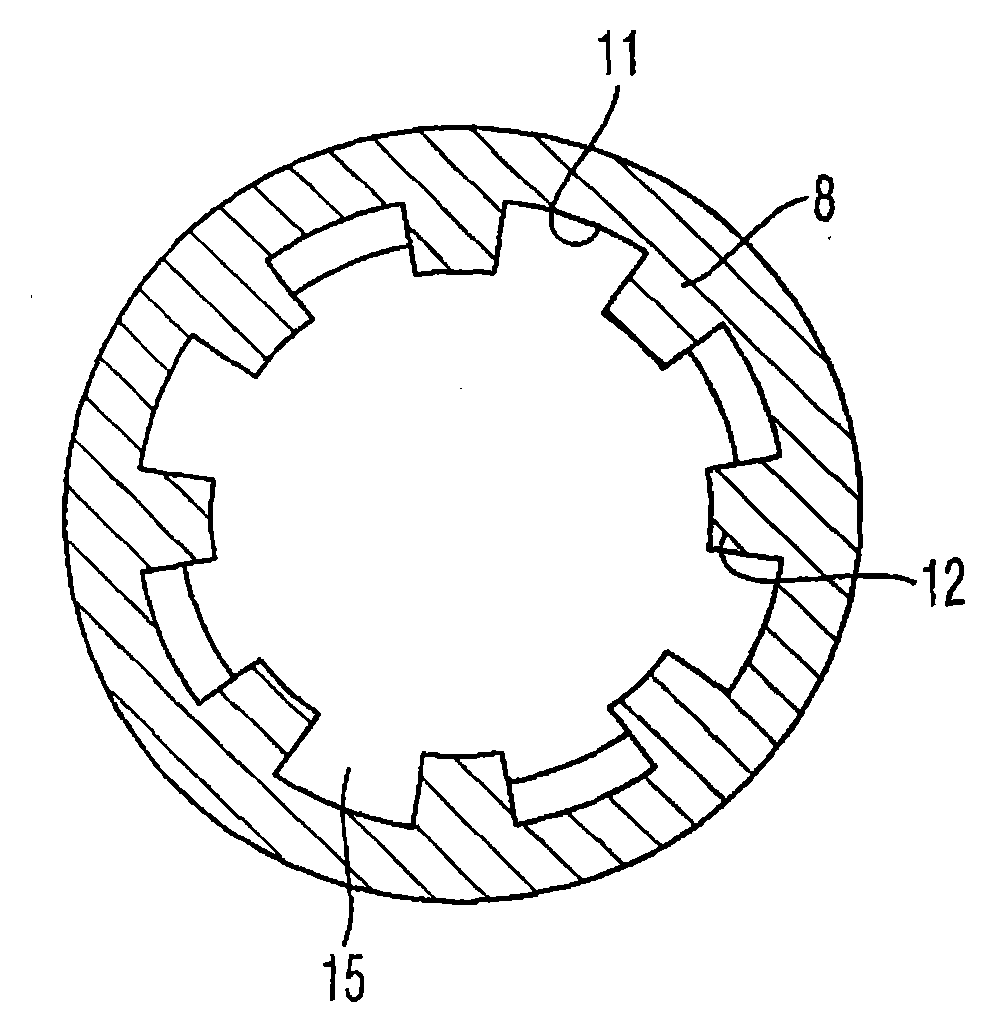

[0039] The following are also used for reference Figure 1 to Figure 5 A first exemplary embodiment of a directional control valve 1 with a ballpoint pen mechanism 2 , in particular for controlling hydraulic fluid flows, is shown in a first switching position. The directional control valve 1 has a control piston 6 with a fluid groove 28 . The control piston 6 has a cylindrical basic shape, wherein a fluid groove 28 in the form of an annular groove 28 is arranged in an outer surface of the control piston 6. The control piston 6 is arranged, for example, preferably axially displaceable in a valve opening 26 of the directional control valve 1 . The valve bore 26 is preferably arranged in a valve body 27 . A plurality of fluid conduits 30 , 31 passing through the valve hole 26 are disposed in the valve body 27 . The fluid lines 30 , 31 are here arranged axially along a central axis 39 of the valve opening 26 , preferably spaced apart from one another. The valve bore 26 is pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com