Linear electric motor for an oilfield pump

a linear electric motor and oilfield pump technology, applied in the direction of positive displacement liquid engine, fluid removal, borehole/well accessories, etc., can solve the problem of inherently high operating costs of wells, insufficient output, and inability to reliably achieve the output level of the pump. the problem of insufficient output is not easy to solve, and the output of conventional large-scale equipment is difficult to achieve. the problem of imprecise manner and high cost of capital equipment expenditures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

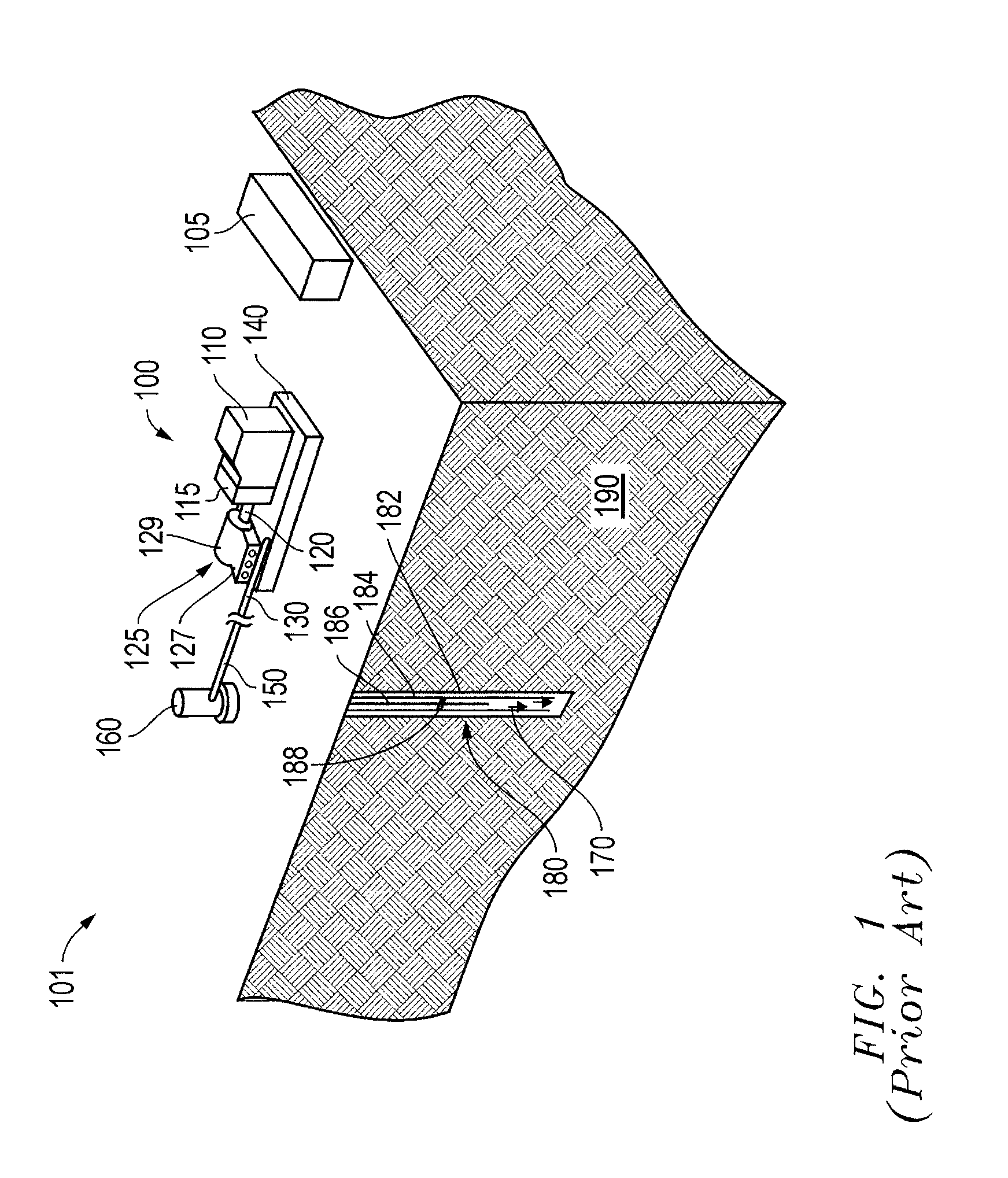

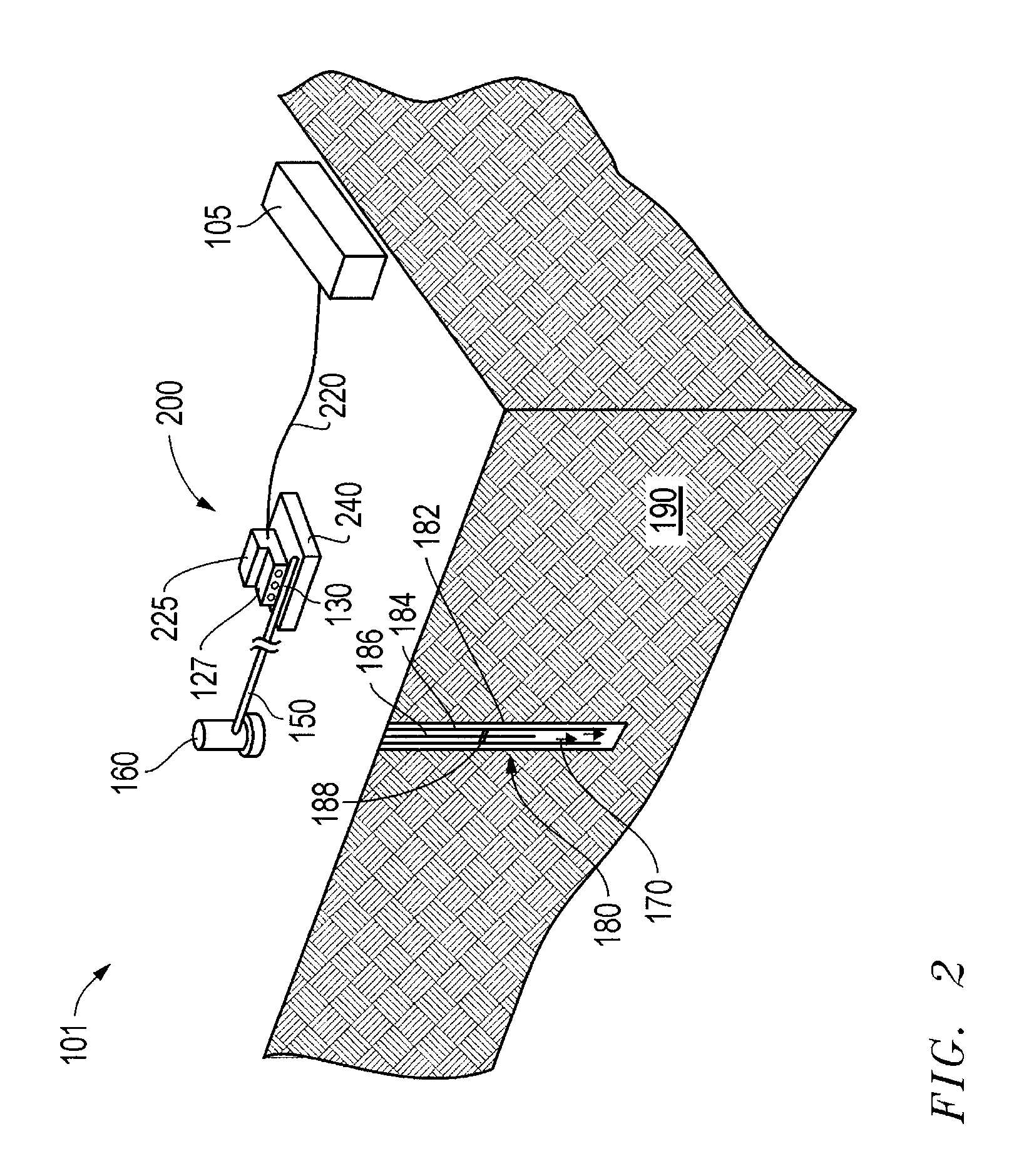

[0014]Embodiments are described with reference to certain linear electric motor (LEM) pump assemblies, particularly for cementing operations at an oilfield. However, other operations may be addressed at the oilfield employing LEM pump assembly embodiments described herein. For example, LEM pump assemblies described herein may be employed in fracturing, drilling, dosing, and other fluid delivery operations at an oilfield. Regardless, embodiments described herein include the use of an LEM to drive an oilfield pumping assembly, as opposed to crankshaft or hydraulic driving techniques, thereby potentially reducing equipment parts and maintenance expenses and increasing the precision and control over the fluid delivery as compared to conventional crankshaft or hydraulic driven pump assemblies.

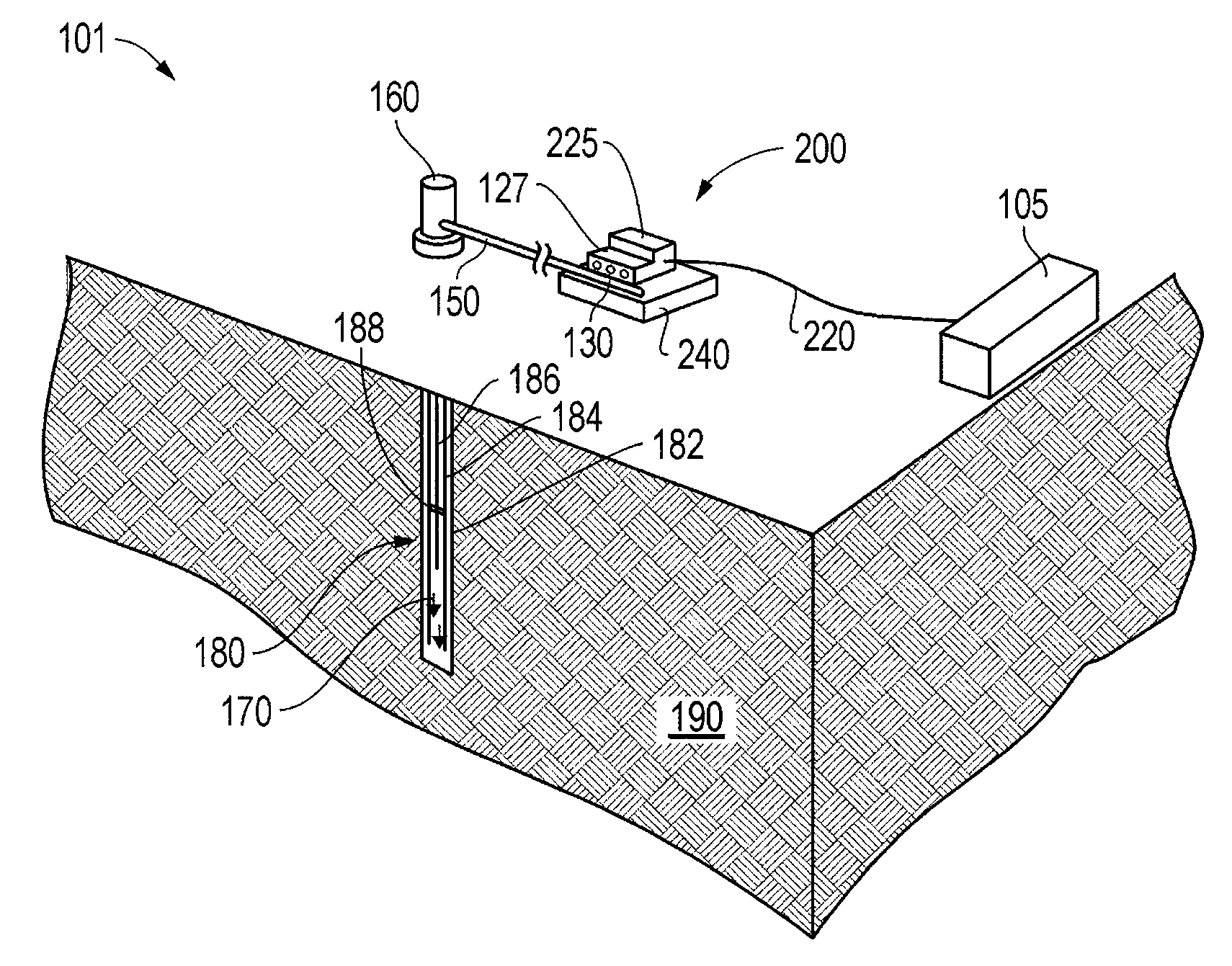

[0015]Referring now to FIGS. 1 and 2, a prior art crankshaft pump assembly 100 employing a variety of equipment for operation may be viewed in light of a linear electric motor (LEM) pump assembly 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com