Terminal electric tape automatic winding apparatus

A technology of insulating tape and winding device, which is used in transportation and packaging, equipment for connecting/terminating cables, sending objects, etc., can solve problems such as low work efficiency, a lot of manpower and material resources, and unsatisfactory winding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

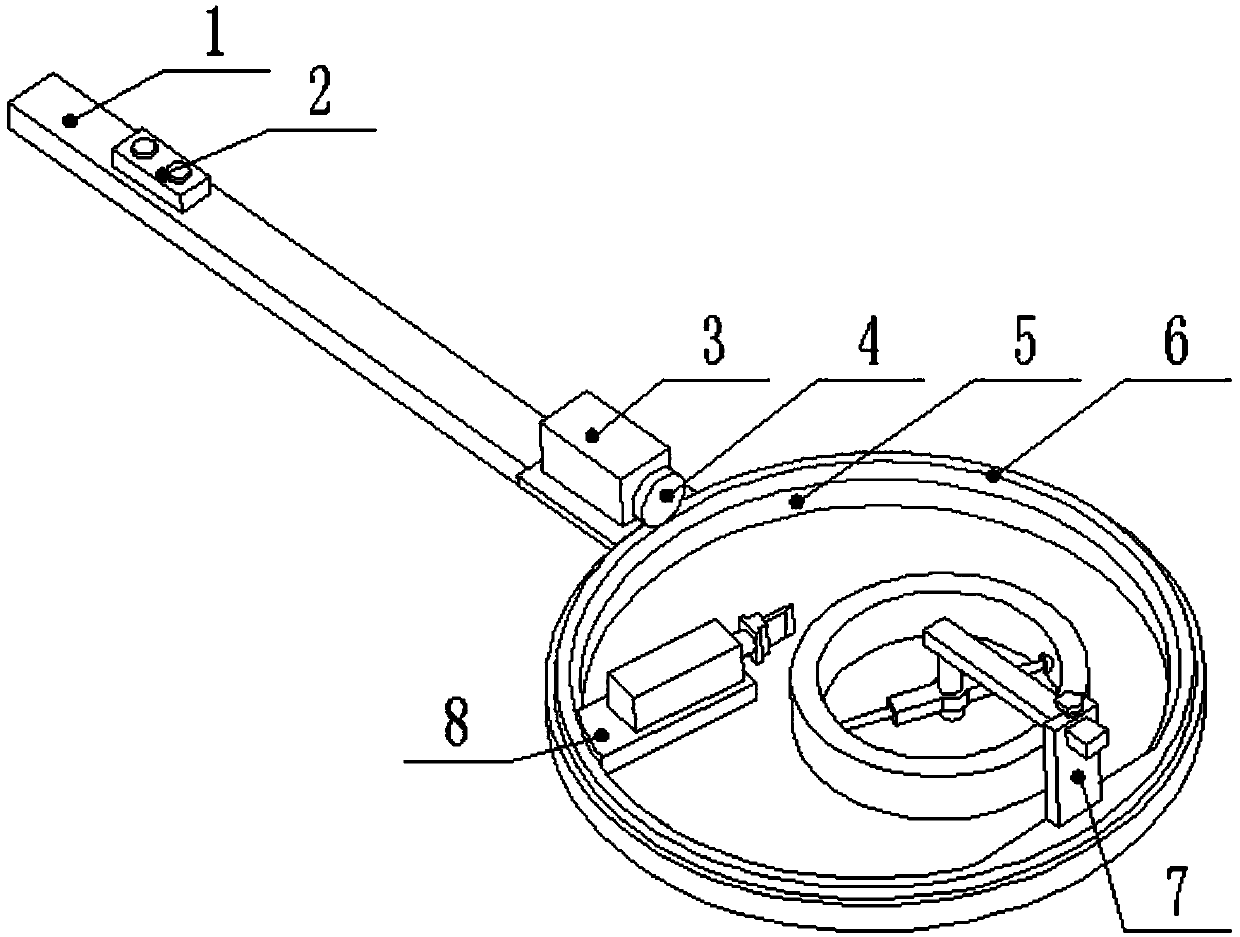

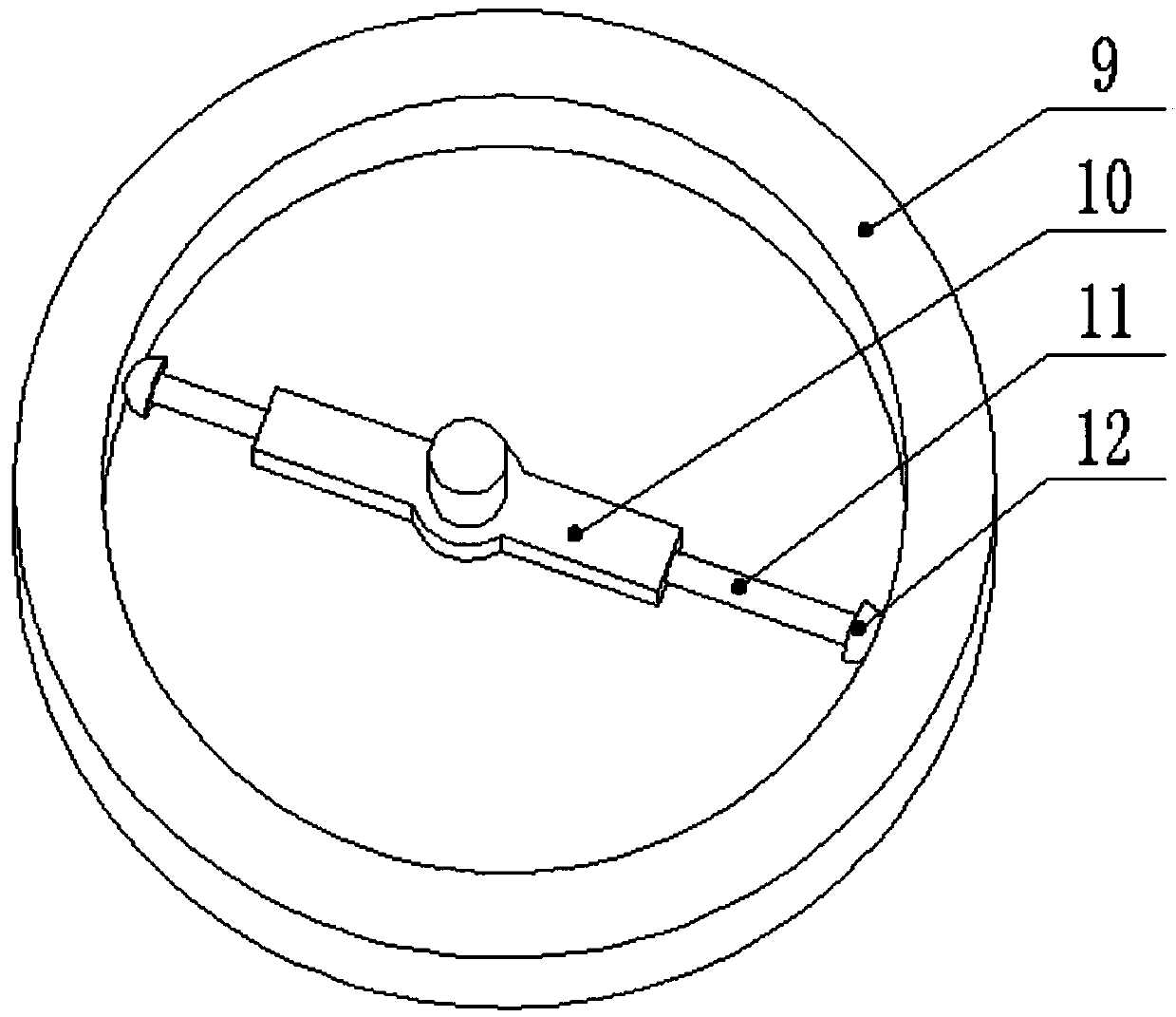

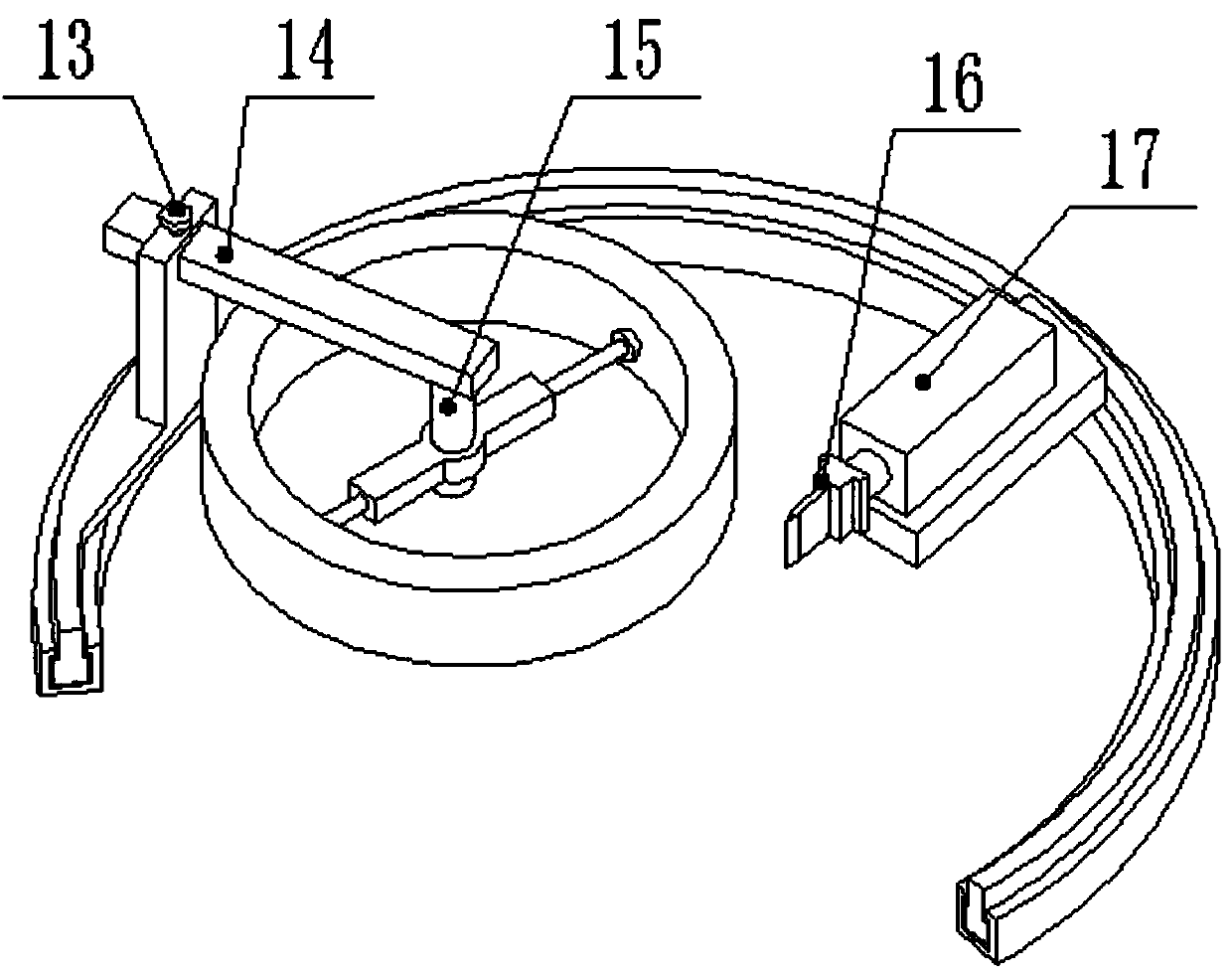

[0017] The present invention is achieved through the following technical solutions: an automatic winding device for insulating tape at the end, including a hand-held base frame 1, a controller 2, a motor 3, a friction wheel 4, a sliding track 5, a rotating ring 6, a first bracket 7, Second support 8, insulating tape roll 9, damping wheel 10, fixed screw rod 11, antiskid ball 12, fixed bolt 13, the 3rd support 14, damping shaft 15, blade 16 and electromagnet 17, described hand-held base frame 15 and sliding The track is connected, and the user can extend the device into some difficult-to-reach positions through the handheld base frame 1. The controller 2 is installed on the handheld base frame, which is fixed at the end of the handheld base frame 1 near the handle, and is used to control the motor. 3 and the action of the electromagnet 17, the motor 3 is installed on the hand-held base frame 1, and it is fixed on the other end of the hand-held base frame 1 away from the handle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com