Full-automatic lithium ion polymer battery four-in-one device with bent side edges

A lithium ion and polymer technology, applied in the field of fully automatic lithium ion polymer battery side bending four-in-one equipment, can solve the problem of no auxiliary control measures, poor appearance, size, performance, inability to improve bottom corner cracks, etc. problem, to improve the appearance of the product, the fit is firm and reliable, and the size is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

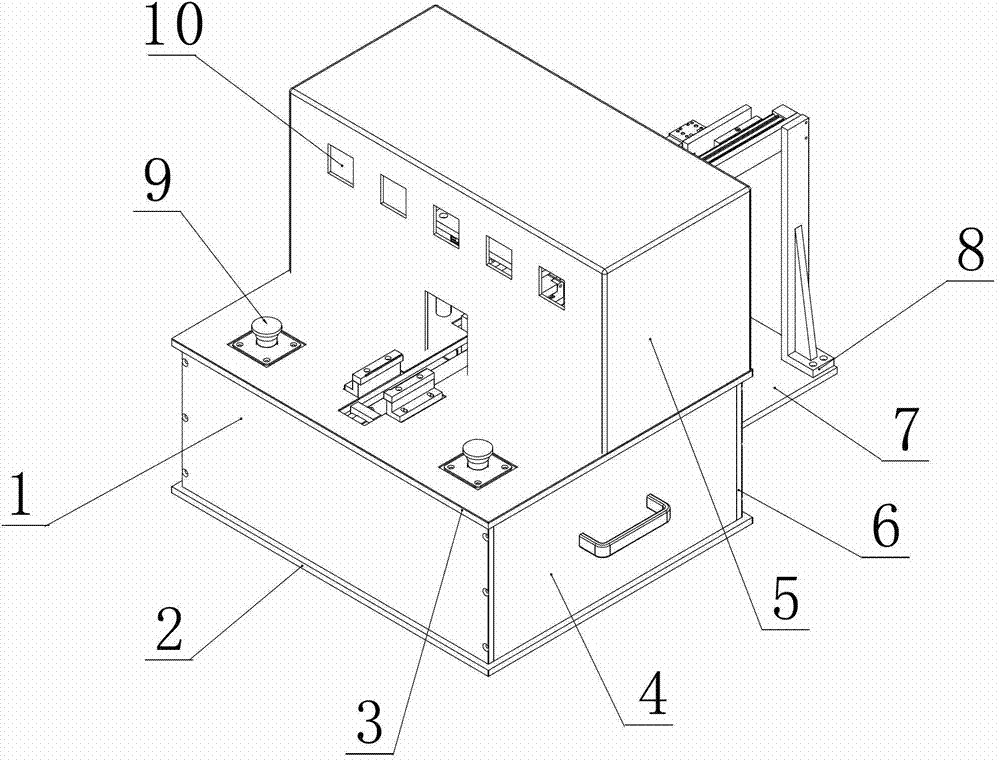

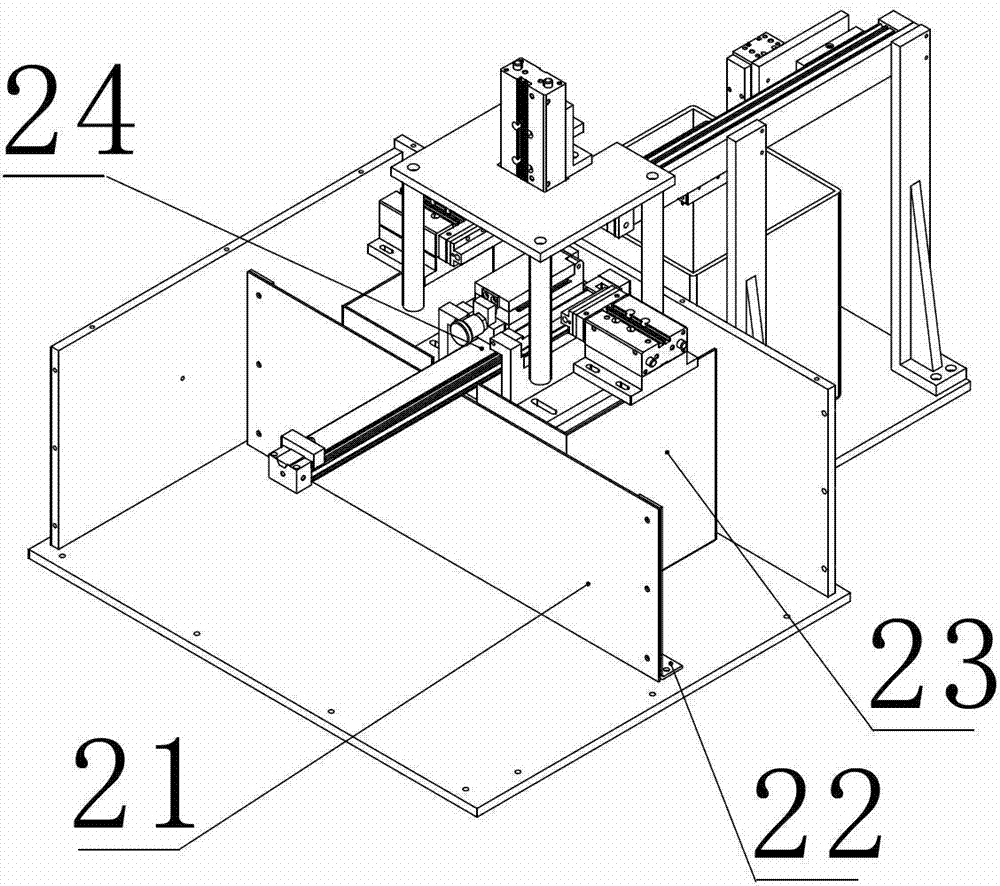

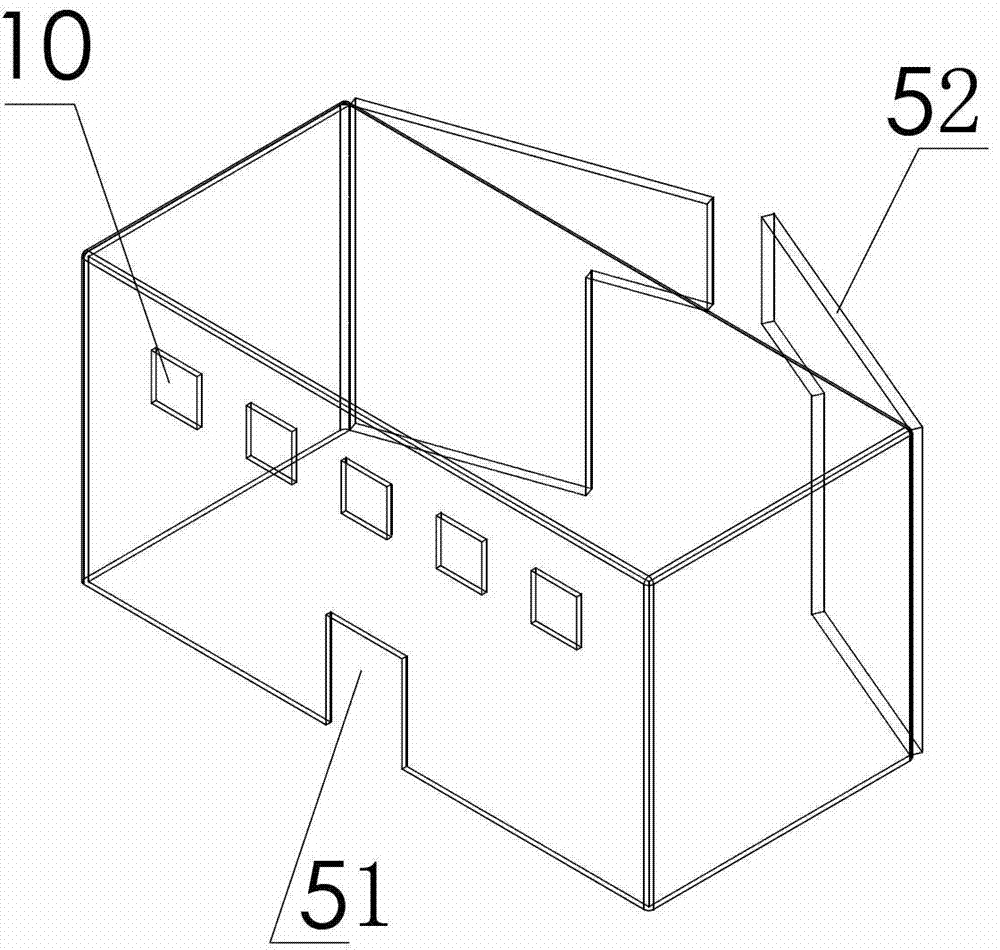

[0034] The present invention is achieved in this way, a fully automatic lithium ion polymer battery side bending four-in-one equipment, including a frame, a loading and unloading mechanism installed and connected through the frame, a preheating mechanism, and a tear-off paper Mechanism, side bending mechanism, constant temperature shaping mechanism, and electrical control device; the loading and unloading mechanism includes a battery fixture, which is used to position the battery to be folded with insulating tape on the side, put it into the battery fixture, and then send it to the battery fixture for processing position; the preheating mechanism includes upper and lower preheating blocks arranged oppositely, which are used to simultaneously preheat the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com