Square winding type battery pole piece and manufacturing technology thereof

A battery pole piece and winding technology, which is applied in the field of square winding battery pole piece and its manufacturing process, can solve the problems of complex stacked battery processing technology, reduced battery capacity performance, and reduced battery capacity, so as to avoid Glitch short circuit condition, increase capacity, effect of capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

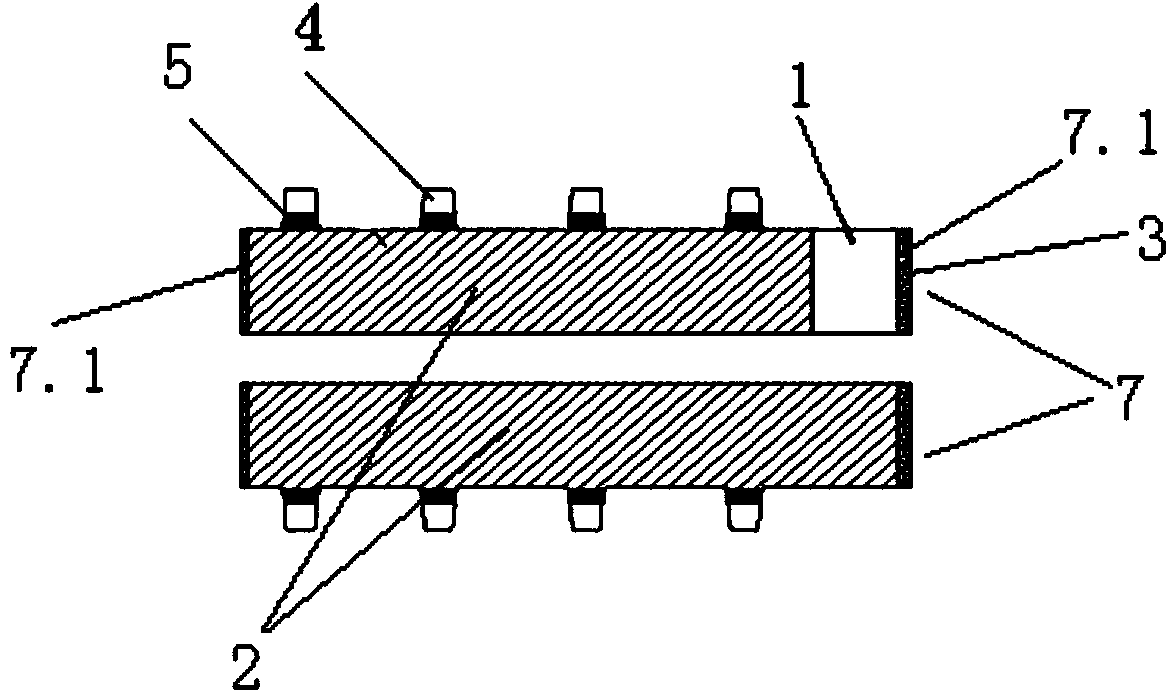

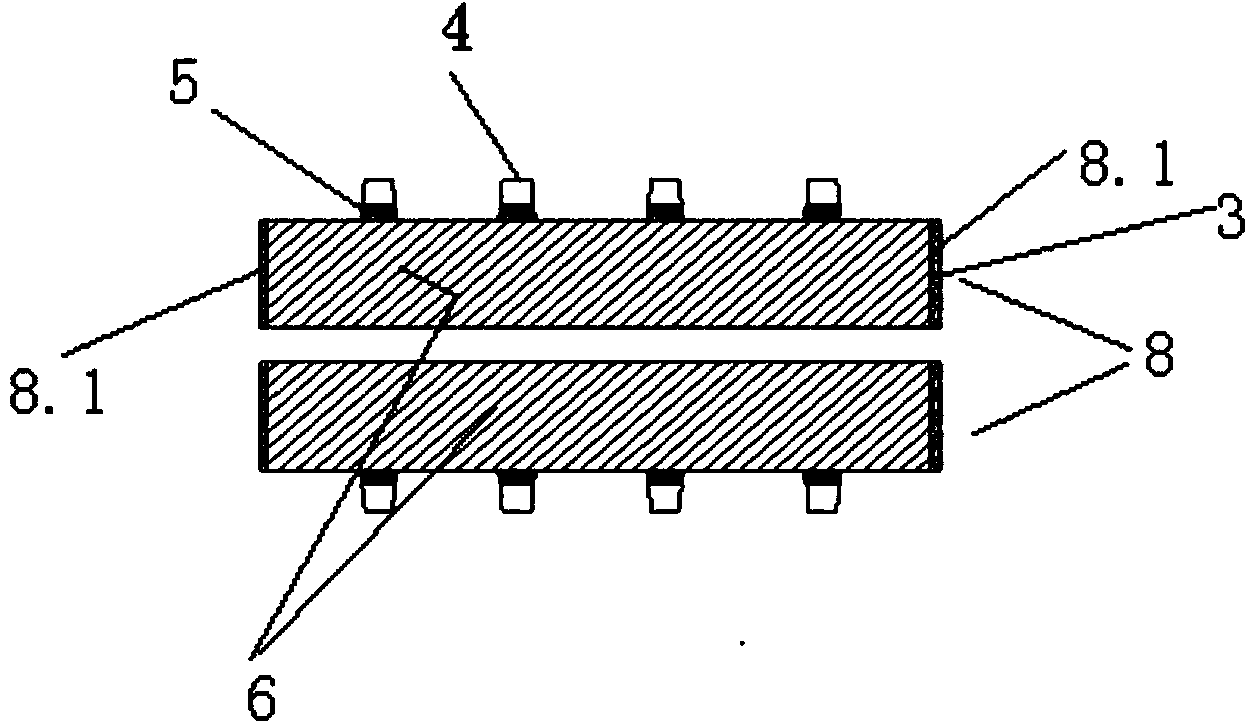

[0016] Such as figure 1 and figure 2 As shown, a square winding battery pole piece is composed of a positive current collector 7, a negative current collector 8, and a positive electrode application area 2 and a negative electrode application area 6 coated on the positive current collector 7 and negative current collector 8. One edge of the positive current collector 7 and the negative current collector 8 is provided with protruding lugs 4, the root of the protruding lugs 4 is provided with an insulating rubber coating 5, and the edges of both sides of the positive current collector 7 are provided with Positive electrode small blank 7.1, negative electrode small blank 8.1 is provided on both sides of the negative current collector 8, the positive electrode small blank 7.1 and the negative electrode small blank 8.1 are pasted with insulating tape 3, the positive electrode application area 2 A large space 1 is provided between the positive minimum space 7.1 on one side edge. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com