Insulating tape and preparation method thereof

A technology of insulating tape and manufacturing method, which is applied in the direction of adhesive, film/sheet adhesive, etc., can solve the problems of complicated production process of insulating tape, damage to insulating coils of insulation grade, and high equipment requirements, and achieves the effect of ultraviolet rays and ozone. Stabilization, improvement of stability and heat resistance, effect of heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

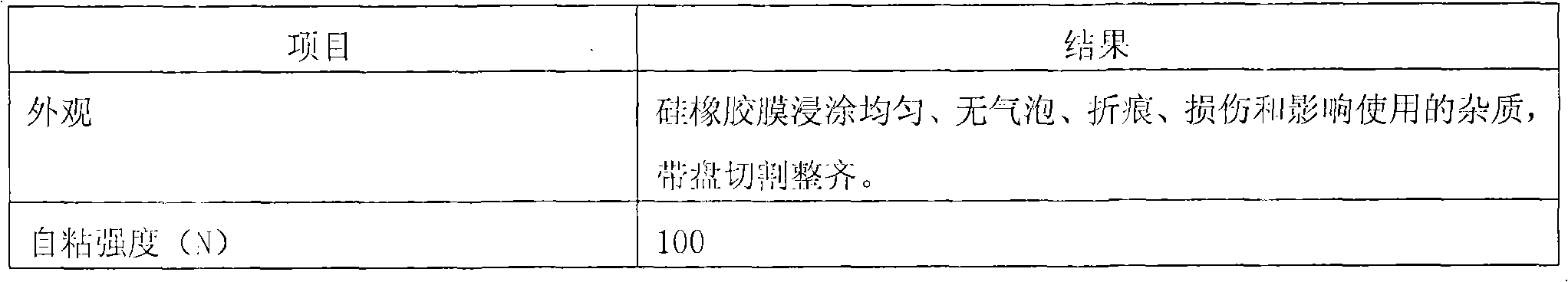

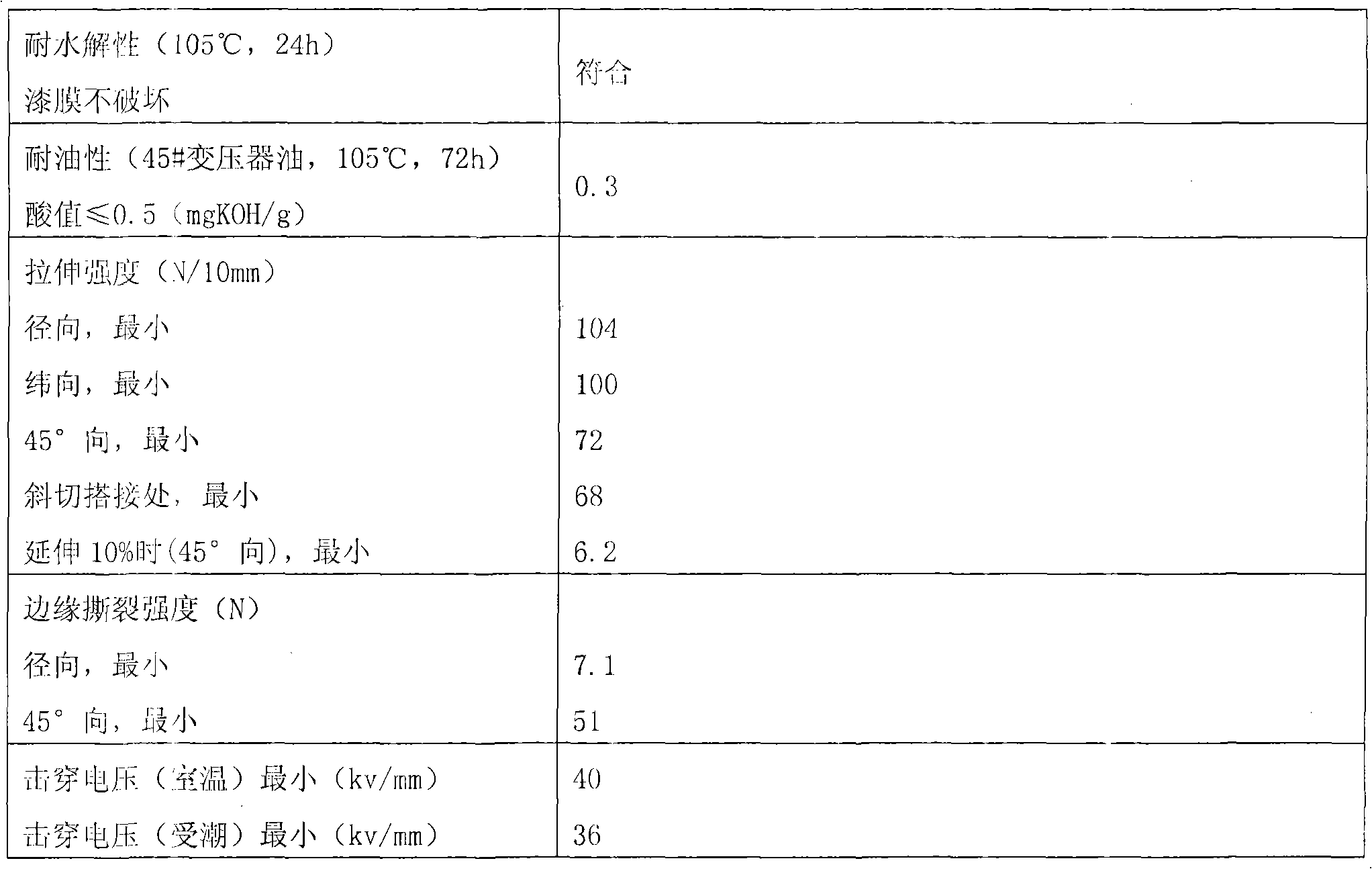

Embodiment 1

[0027] The insulating tape of this embodiment is made of 2551-type glass fiber cloth coated with insulating adhesive material on both sides, and the insulating adhesive material component and weight ratio are silicone rubber 110-2: 65%, silicone rubber 107: 12.5%, Boric acid: 1.5%, white carbon black A200: 15%, hydroxy silicone oil GY2009-3: 2%, ferric oxide: 2%, vulcanizing agent: 2%, and the remaining solvent is xylene.

[0028] 1) Preparation of micelles: Mix 3750g of silicone rubber 107 and 450g of boric acid, put them in two trays, and place them in the upper and lower layers of the oven for baking respectively. The baking is divided into five consecutive temperature changing periods, which are 75°C, 50min——10°C , 60min——150°C, 70min——180°C, 70min——turn off the power and keep warm for 50min, and the upper and lower layers of micelles should be stirred and mixed evenly in the gap between each time period;

[0029] 2) Mixing: mix the micelles with 19,500g of silicone rubber...

Embodiment 2

[0039] The insulating tape of this embodiment is made of 2551-type glass fiber cloth tape coated with insulating adhesive material on both sides and compounded. The components and weight ratio of the insulating adhesive material are silicone rubber 110-2: 73%, silicone rubber 107: 12%, Boric acid: 1%, white carbon black A200: 10%, hydroxyl silicone oil GY2009-3: 1%, ferric oxide: 1.5%, vulcanizing agent BP: 1.5, and other solvents are xylene.

[0040] The operating steps are the same as in Example 1.

[0041] Verification results The self-adhesive strength is 102N, the minimum radial tensile strength is 105N / mm, the minimum radial edge tear strength is 7.8N, and the minimum breakdown voltage (at room temperature) is 38kv / mm.

Embodiment 3

[0043] The insulating adhesive tape of this embodiment is made of 2551-type glass fiber cloth tape coated with insulating adhesive material on both sides and compounded. The components and weight ratio of the insulating adhesive material are silicone rubber 110-2: 70%, silicone rubber 107: 14%, Boric acid: 1%, white carbon black A200: 10%, hydroxyl silicone oil GY2009-3: 1.5%, ferric oxide: 2%, vulcanizing agent BP: 1.5%, and the remaining solvent is xylene.

[0044] The operating steps are the same as in Example 1.

[0045] Verification results The self-adhesive strength is 105N, the minimum radial tensile strength is 108N / mm, the minimum radial edge tear strength is 8N, and the minimum breakdown voltage (at room temperature) is 42kv / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown voltage | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com