Crosslinked polyethylene welding type insulated cable joint and manufacturing and installation processes thereof

A cross-linked polyethylene, insulated cable technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulators, etc., can solve the problems of low production efficiency, high technology participation, and difficult production, and achieve simple, convenient and successful manufacturing and installation processes The effect of improving rate and efficiency and avoiding partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

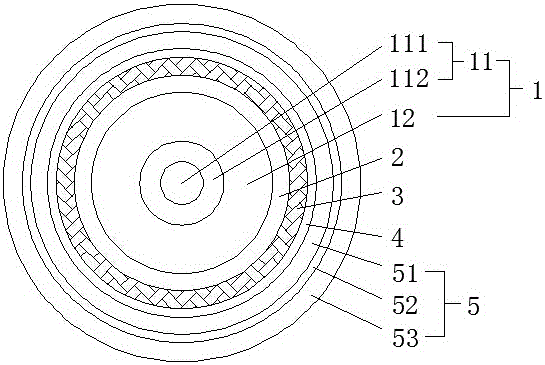

[0036] see figure 1 , this embodiment includes a cable 1 , a shielding layer 2 , a copper shielding net 3 , an inner sheath 4 and an outer sheath 5 from inside to outside.

[0037] The cable 1 includes a conductive layer 11 and an insulating layer 12 from inside to outside, and the conductive layer 11 includes a conductor layer 111 and an inner semiconductor layer 112 from inside to outside. The insulating layer 12 is directly wrapped outside the inner semiconducting layer 112 by cross-linked cross-linked polyethylene tape and overlapped with the insulation layer of the original cable, and then the cross-linked polyethylene tape is melted by heating to form insulation with the original cable The cross-linked polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com