Multi-layer insulated electrical wire

A multi-layer insulation and wire technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of poor insulation, cumbersome operations, and human resources consumption, and achieve good insulation effect and good voltage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

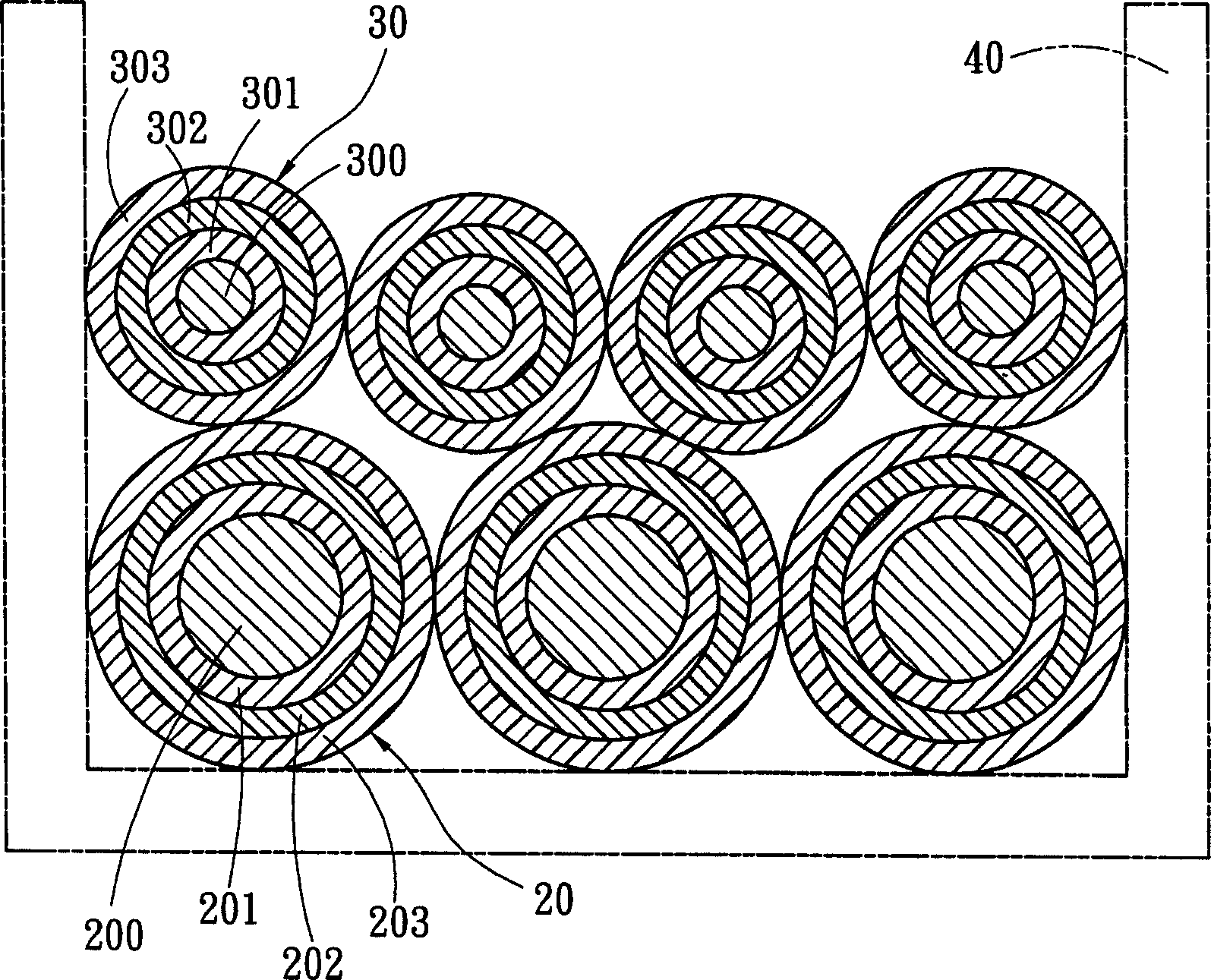

[0015] The preferred embodiments and technical contents of the present invention are described as follows in conjunction with the accompanying drawings:

[0016] The present invention utilizes the material characteristics of fluorine-containing thermoplastic plastics to avoid the complicated production procedures caused by the use of insulating tapes and insulating sleeves in the past, and can also meet the requirements for the thickness of the insulating layer of wires in safety regulations. The multi-layer insulated wire of the invention is described in detail as follows in conjunction with the accompanying drawings:

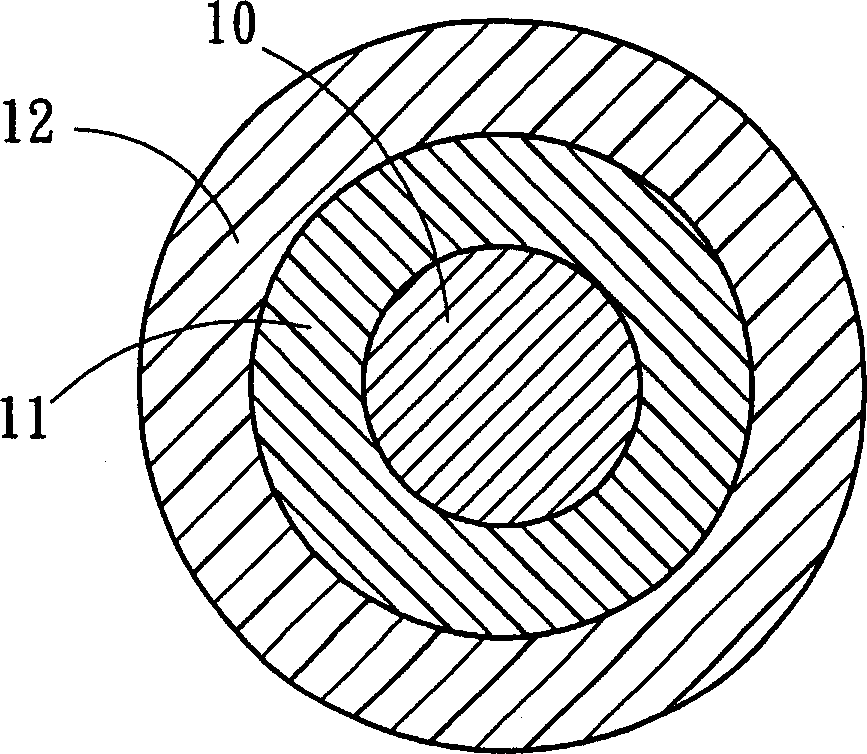

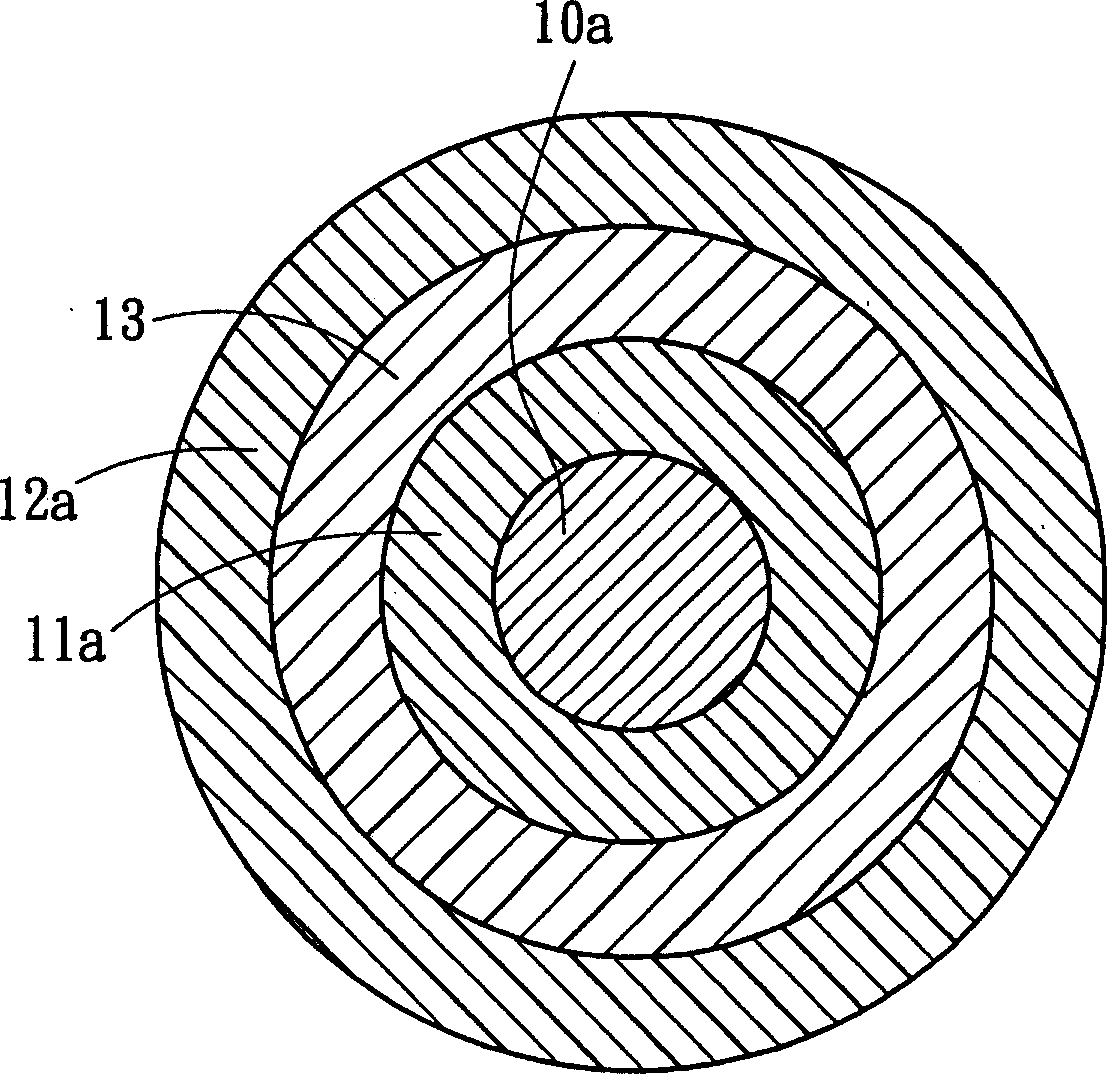

[0017] see figure 1 Shown is a sectional view of the present invention. The multilayer insulated wire of the present invention includes a conductor 10 and an insulating layer covering the aforementioned conductor 10 and having an inner layer 11 and an outer layer 12. The insulating layer is made of fluorine-containing thermoplastic Plastic is formed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com