Method for making self-adhesive insulating tape

An insulating tape and a technology of a manufacturing method, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of inability to prolong service life, damage of insulating coils, and complex production process of pure silicone rubber and other problems, to achieve the effect of simple process, less energy consumption and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

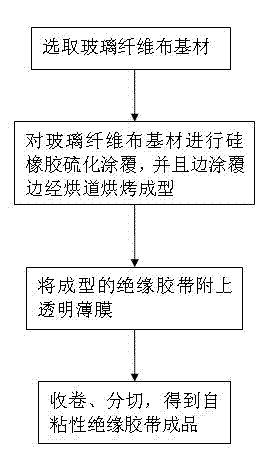

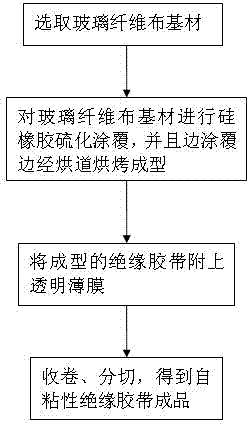

Image

Examples

Embodiment 1

[0024] Select the base material of glass fiber cloth; vulcanize and coat the base material of glass fiber cloth with silicone rubber for 1.5 hours, and bake it in a drying tunnel at 120°C while coating, wherein the silicone rubber is composed of: methyl 100 parts of vinyl silicone rubber, 15 parts of white carbon black, 5 parts of tackifier, 2 parts of hydroxyl silicone oil, and 2 parts of iron red are vulcanized by radiation; the formed insulating tape is attached with a transparent film; winding, cutting, A finished self-adhesive insulating tape is obtained.

[0025] Test results: self-adhesive strength 10N / 25mm, tensile strength 1000N / 25mm.

Embodiment 2

[0027] Select the base material of glass fiber cloth; vulcanize and coat the base material of glass fiber cloth with silicone rubber for 1.5 hours, and bake it in a drying tunnel at 120°C while coating, wherein the silicone rubber is composed of: methyl 100 parts of vinyl silicone rubber, 10 parts of white carbon black, 15 parts of tackifier, 1 part of hydroxy silicone oil, 1.5 parts of iron red are vulcanized by radiation; attach the formed insulating tape to a transparent film; winding, cutting, A finished self-adhesive insulating tape is obtained.

[0028] Test results: self-adhesive strength 12N / 25mm, tensile strength 1000N / 25mm.

Embodiment 3

[0030] Select the base material of glass fiber cloth; vulcanize and coat the base material of glass fiber cloth with silicone rubber for 1.5 hours, and bake it in a drying tunnel at 120°C while coating, wherein the silicone rubber is composed of: methyl 100 parts of vinyl silicone rubber, 10 parts of white carbon black, 10 parts of tackifier, 1.5 parts of hydroxy silicone oil, 2 parts of iron red are made by radiation vulcanization; the formed insulating tape is attached with a transparent film; winding, cutting, A finished self-adhesive insulating tape is obtained.

[0031] Test results: self-adhesive strength 15N / 25mm, tensile strength 1000N / 25mm.

[0032] The invention discloses a method for making a self-adhesive insulating tape, which is formed by coating insulating self-adhesive materials on both sides of a glass fiber cloth base material. Superior performance in terms of tensile strength and viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com