Digital twinning system applied to industrial production and forming method thereof

A twin and digital technology, applied in the field of intelligent manufacturing, can solve the problems of less application of production systems and workshops, immature digital twin technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A digital twin system applied to the industrial production of ultrapure water in the electronics industry

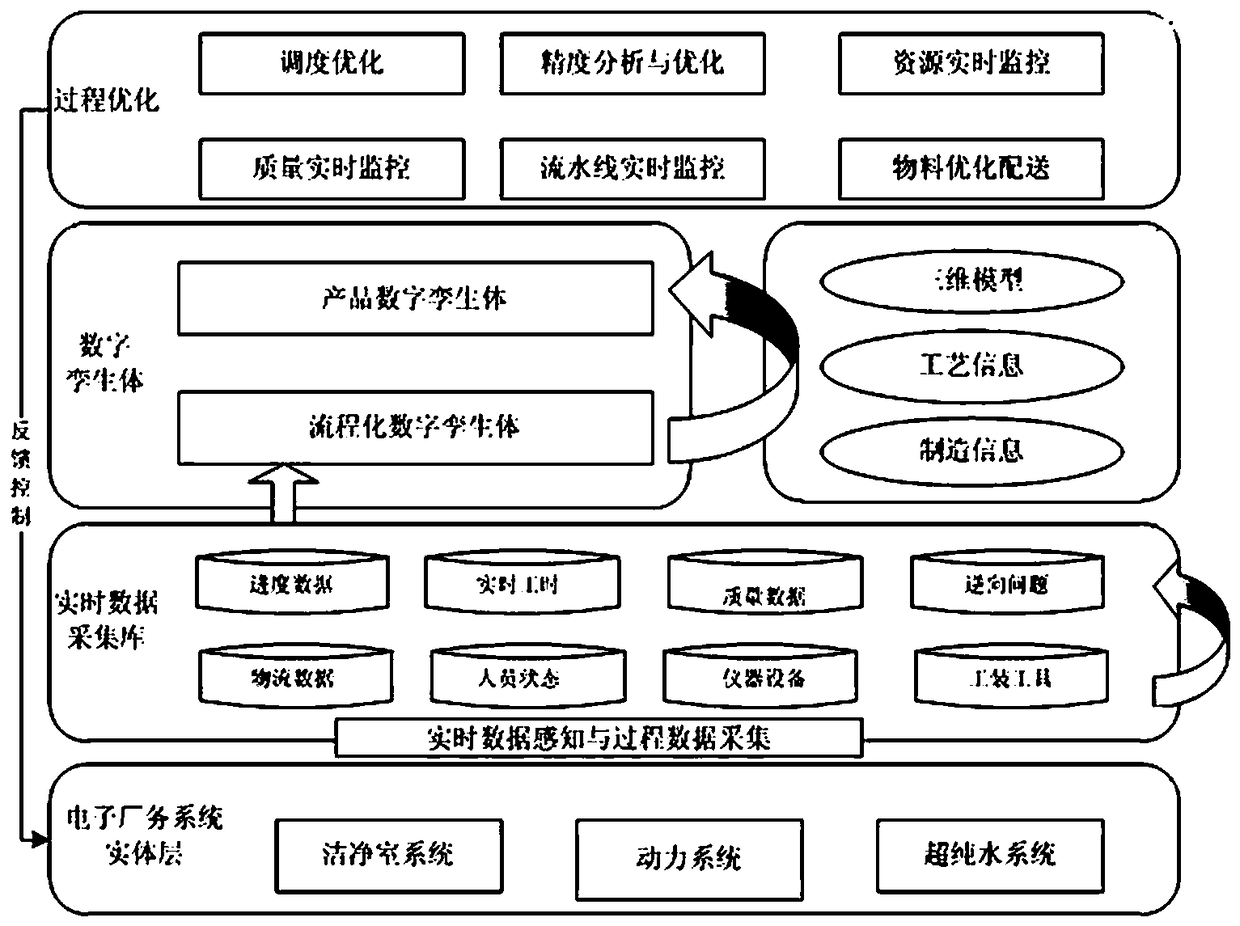

[0027] This embodiment is set based on the current clean room system, power system, and ultrapure water system in the electronics manufacturing industry, and the above three systems all have intelligent control systems. This example image 3 As shown, it includes the physical entity layer, data acquisition layer, digital twin and its information model layer, and process optimization layer connected in sequence, and the process optimization layer is also connected to the physical entity layer through feedback control to form a closed loop.

[0028] Wherein the physical entity layer includes all equipment in the clean room system, the power system, and the ultrapure water system; and the data acquisition layer includes sensors located on each mechanical device of the physical entity layer, and the sensors can collect industrial production progress data in ...

Embodiment 2

[0031] Embodiment 2 A method for forming a digital twin system applied to industrial production in the electronics industry

[0032] This embodiment is the forming method of implementation 1, including the following steps carried out in sequence:

[0033] 1. Form a mapping relationship: Virtualize each device in the physical entity layer and the connections between them to form a mapping relationship between entities and twin digital systems in industrial production.

[0034] This step is carried out according to the following steps:

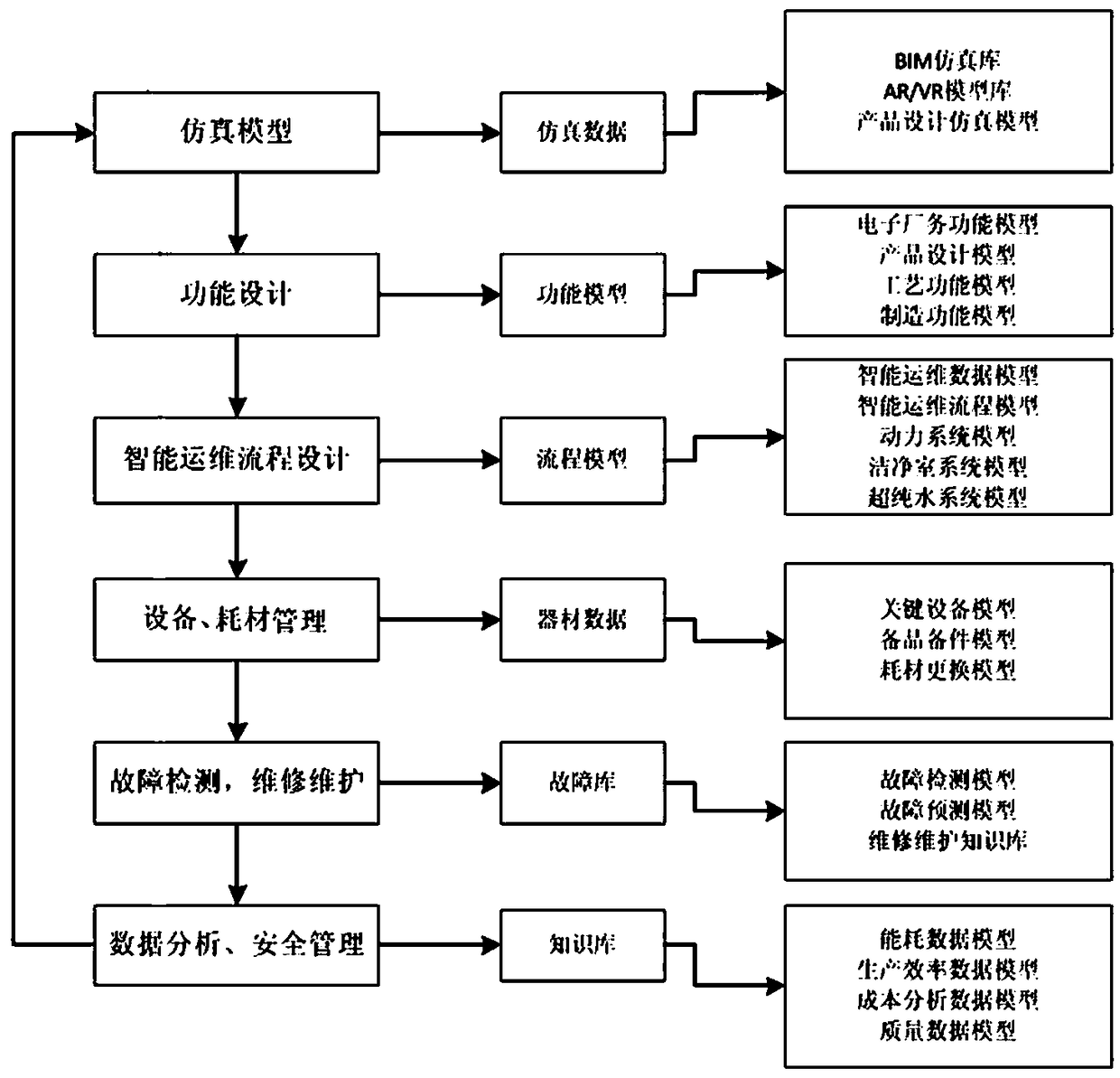

[0035] 1) Establish a simulation analysis model,

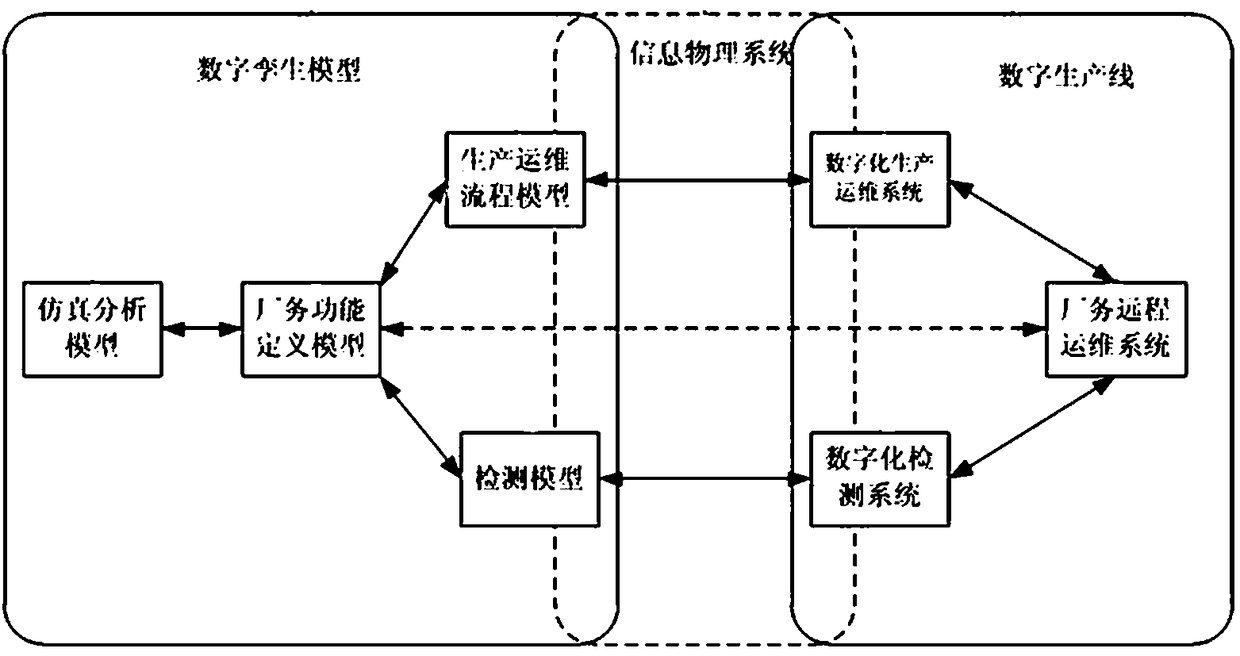

[0036] 2) Define the function of the industrial production system as a digital model, convert the control process of remote operation and maintenance into a digital thread, and form a production operation and maintenance process model established between each thread, and cooperate with the intelligent manufacturing system and digital measurement and inspection system. As well as the results of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com