Device for measuring sediment thickness of pile base of cast-in-situ bored pile

A technology for bored piles and slag thickness, which is used in the testing of foundation structures, construction, foundation structure engineering, etc. The effect of construction quality, reasonable structure and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

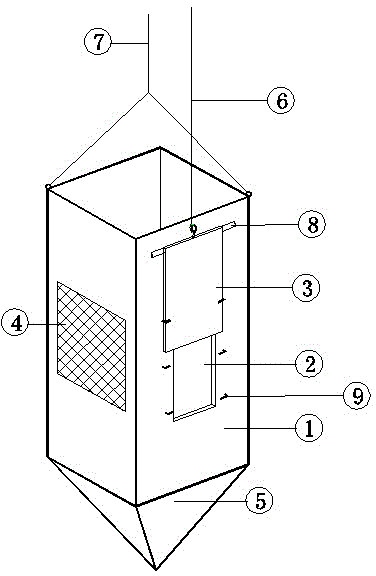

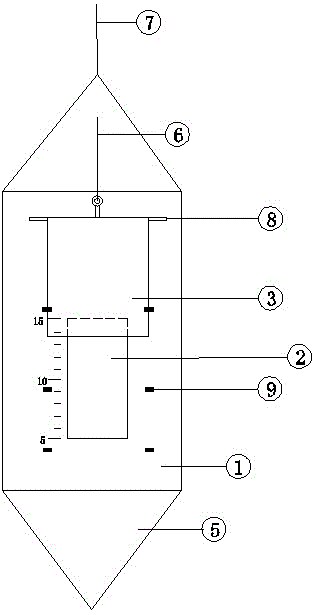

[0018] from figure 1 , figure 2 It can be seen from: a measuring device for the thickness of the sediment at the bottom of the bored pile (referred to as the measuring device), which is characterized in that: the measuring device for the thickness of the sediment at the bottom of the bored pile is mainly composed of a measuring barrel, a gate 3, a main The suspending rope 7 and the pulling rope 6 are formed. The measuring barrel is mainly composed of a barrel body 1 and a barrel bottom 5 made into one piece. The barrel body 1 is a vertical cavity rectangular body, and the barrel bottom 5 is a quadrilateral cone bottom. Both the barrel body 1 and the barrel bottom 5 can be made of steel plate with a thickness of 15mm, the height of the barrel body 1 can be 300mm, and a rectangular slurry feeding hole (port) 2 is opened in the middle and lower part of the right side of the barrel body 1. The height × width of the slurry inlet hole 2 can be 100 × 50mm; a digital scale is engrav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com