Assembly and noise suppressor for firearms

a technology of noise suppressor and firearm, which is applied in the direction of weapon components, muzzle attachments, weapons, etc., can solve the problems of easy cleaning of devices without sophisticated cleaning equipment, and promotion of small impact groups, so as to achieve the effect of not affecting the accuracy of firearms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

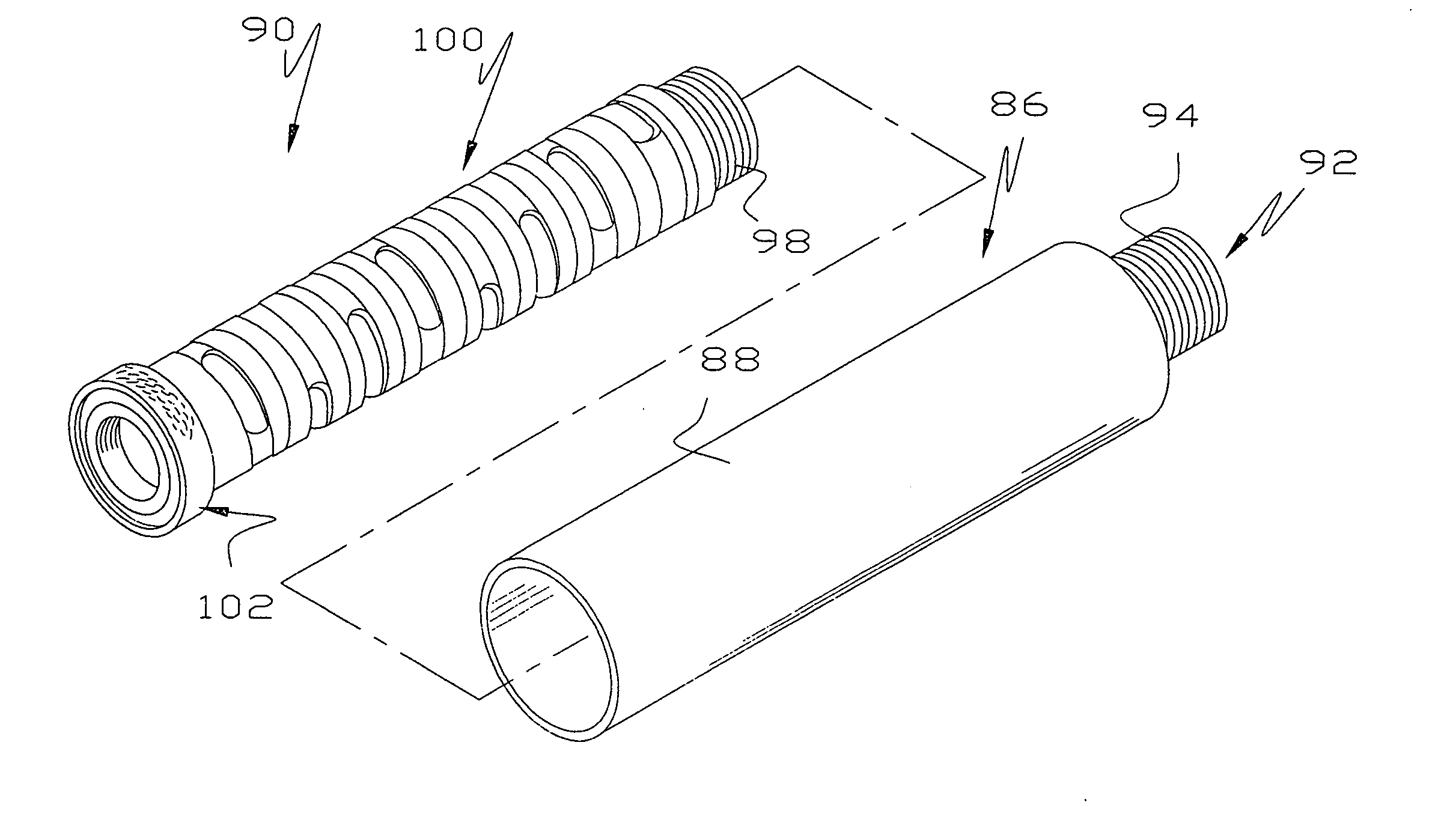

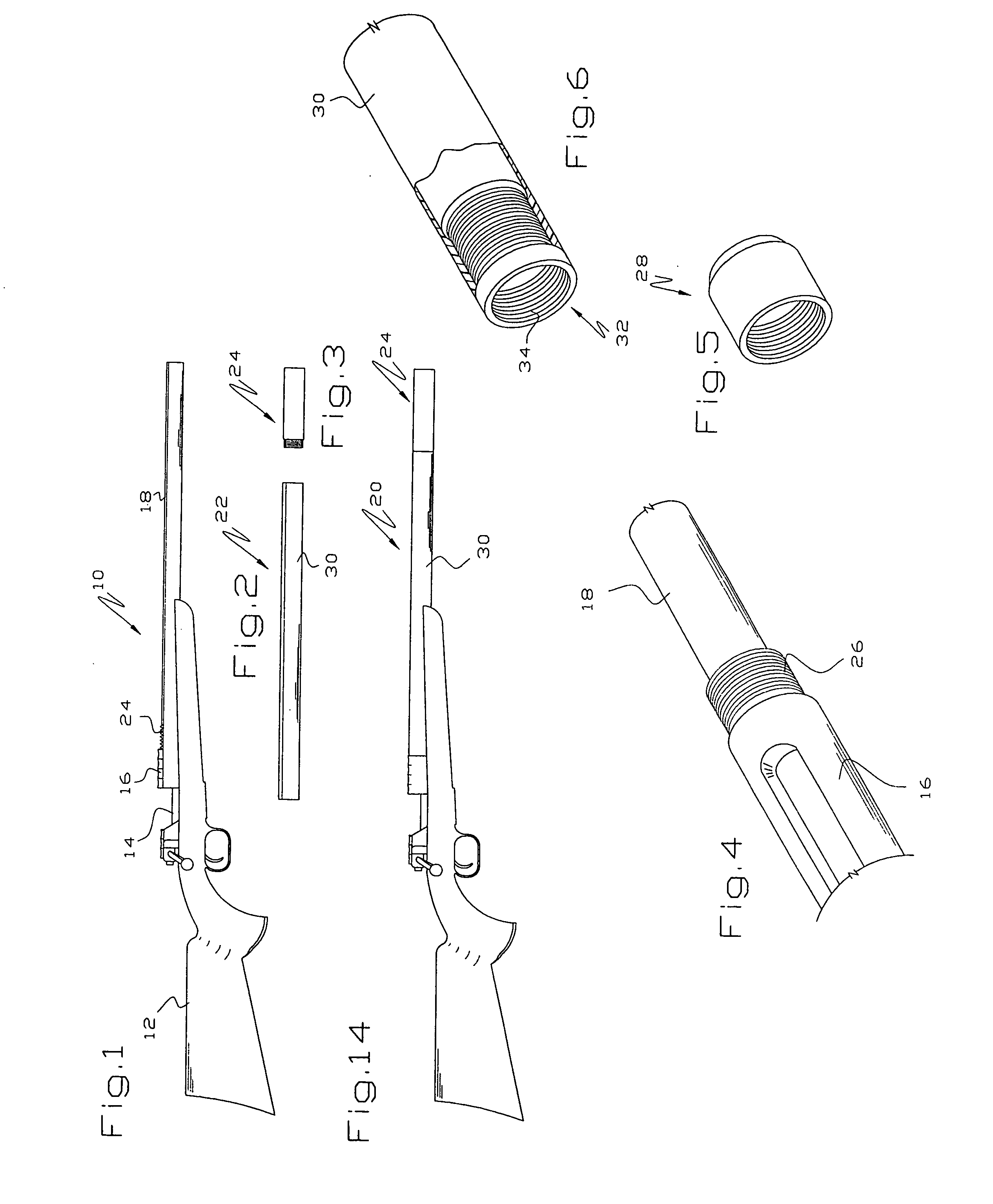

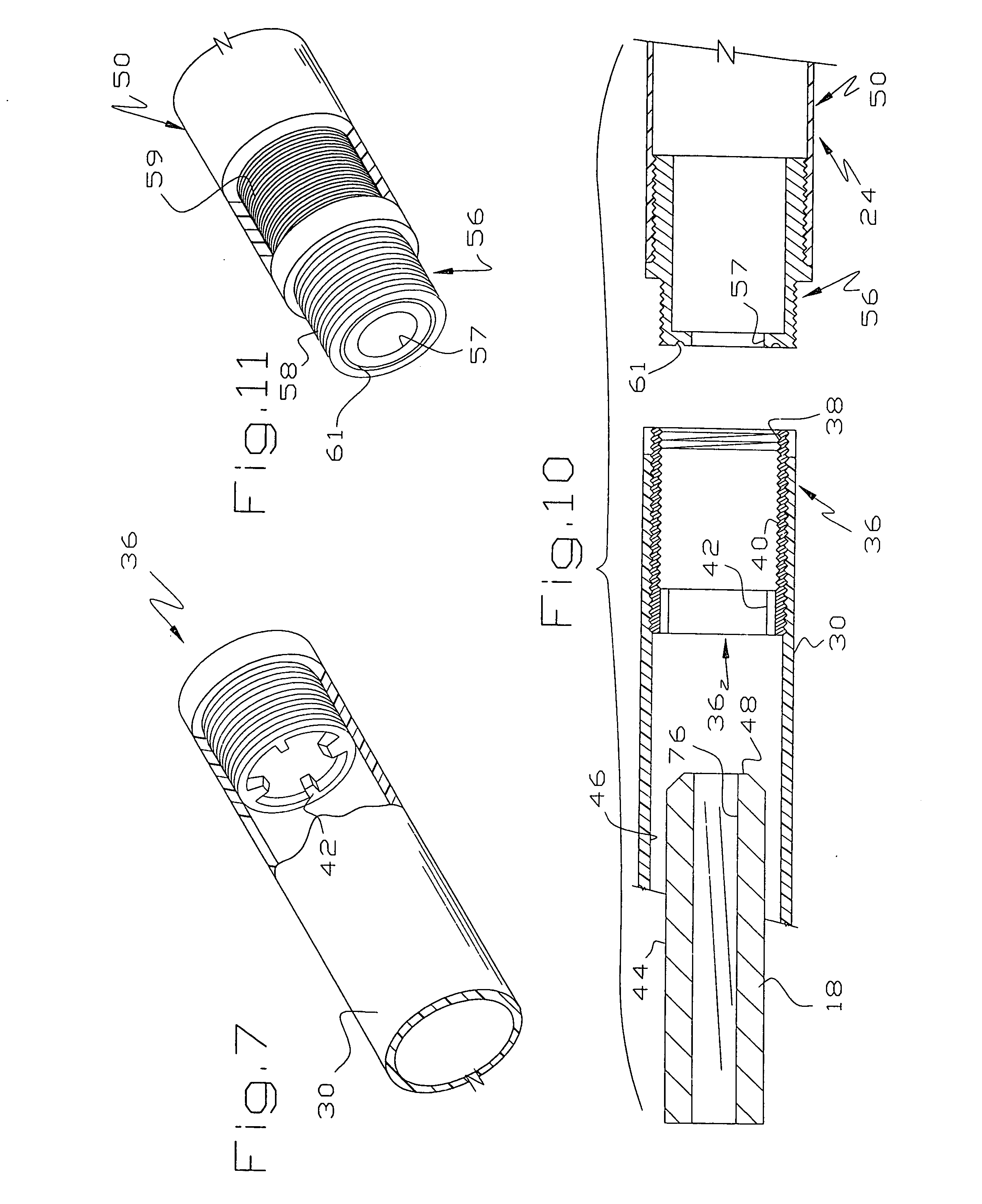

[0027]Referring to FIGS. 1-11, a rifle 10 is illustrated as of a bolt action type having a stock 12, a bolt 14, a receiver 16 and a barrel 18. Those skilled in the art will recognize the rifle 10 as being a conventional rifle known as a Fabrique National (FN) of the free floating barrel type where the barrel is attached to the receiver 16 but is slightly movable relative to the stock 12. Those skilled in the art will recognize that free floating barrel type rifles comprise the majority of modern “counter sniper” weapons, as well as for all versions of the M16 and its civilian version, the AR15.

[0028]As shown by a comparison of FIGS. 1 and 14, the rifle 10 has been modified by incorporating an assembly 20 which includes a rigid imperforate sleeve or tubular beam 22 and a noise suppressor 24. The sleeve 22 is fixed to the receiver 16 or to the barrel 18 adjacent its junction with the receiver 16 in any suitable manner, as by welding, mating threads, adhesives or the like. Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com