Automatic wine-making production line with full-automatic steaming robot

An automated production line and robot technology, applied in the preparation of alcoholic beverages, can solve problems such as rising labor costs and shortage of land resources, and achieve the effects of low labor intensity, high work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

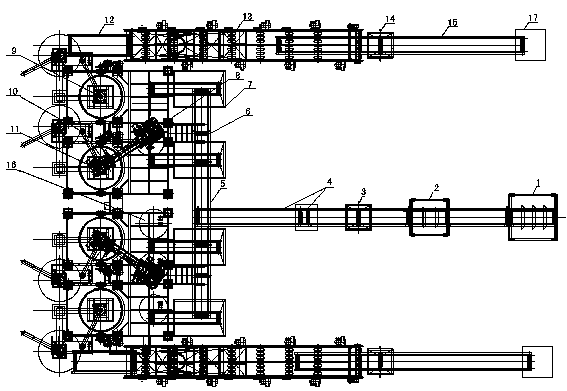

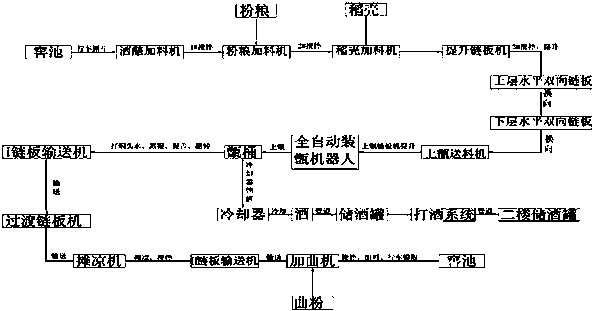

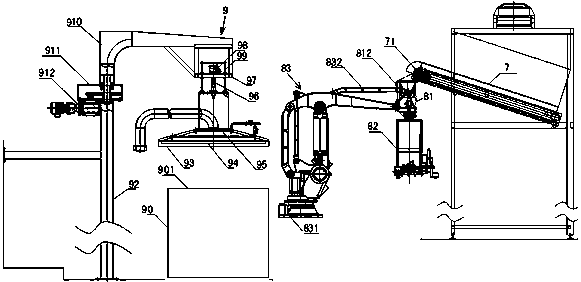

[0026] Such as Figure 1 to Figure 2 As shown, the automatic production line of the present invention includes a wine grains feeding machine 1, a powder grain feeding machine 2, a rice husk feeding machine 3, a lifting chain plate machine 4, an upper horizontal two-way chain plate machine 5, a lower level horizontal Two-way chain plate machine 6, upper retort feeding machine 7, automatic retort loading robot 8, retort barrel 9, cooler 10, I chain plate conveyor 11, transition chain plate machine 12, cooling machine 13, koji adding machine 14, II Chain plate conveyor 15 and wine storage tank 16, described wine grains feeder 1, powder grain feeder 2, rice husk feeder 1 are lined up near the cellar pool, are all connected with lifting chain plate machine 4, lift The discharge end of the chain plate machine 4 is installed with the upper horizontal two-way chain plate machine 5, and the lower horizontal two-way chain plate machine 6 is installed horizontally below the head and tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com