Semi-reverse construction method for combining two walls into one of combined prefabricated pipe barrels of underground comprehensive pipe gallery

A technology of integrated pipe gallery and construction method, which is applied in the direction of building structure, excavation, construction, etc., can solve the problems of long construction period, slow construction speed, high cost, etc., and achieve the goals of saving project cost, improving construction efficiency, and simplifying construction methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

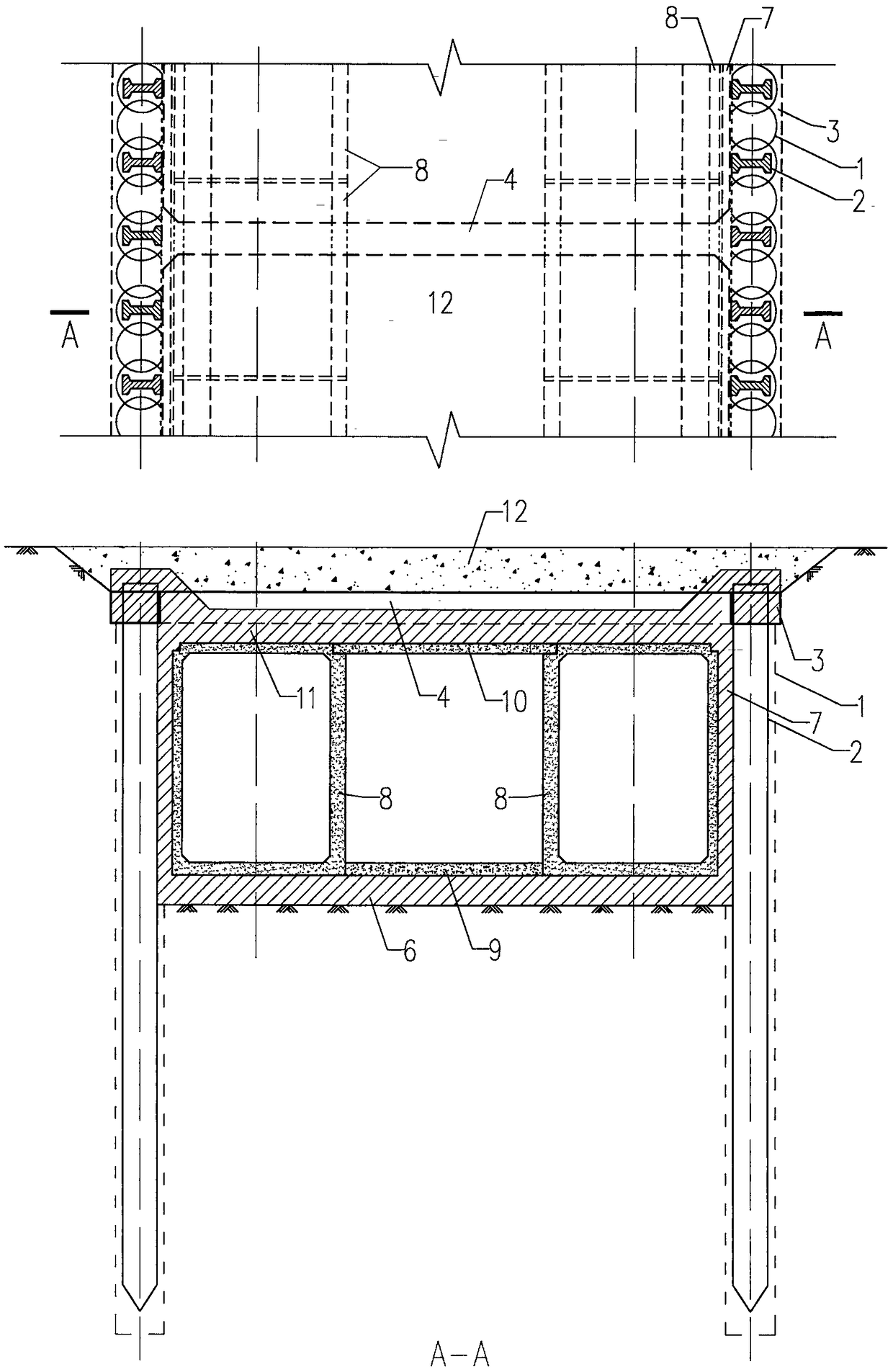

[0049] The construction sequence of the present invention's concrete implementation and each operation point are as follows:

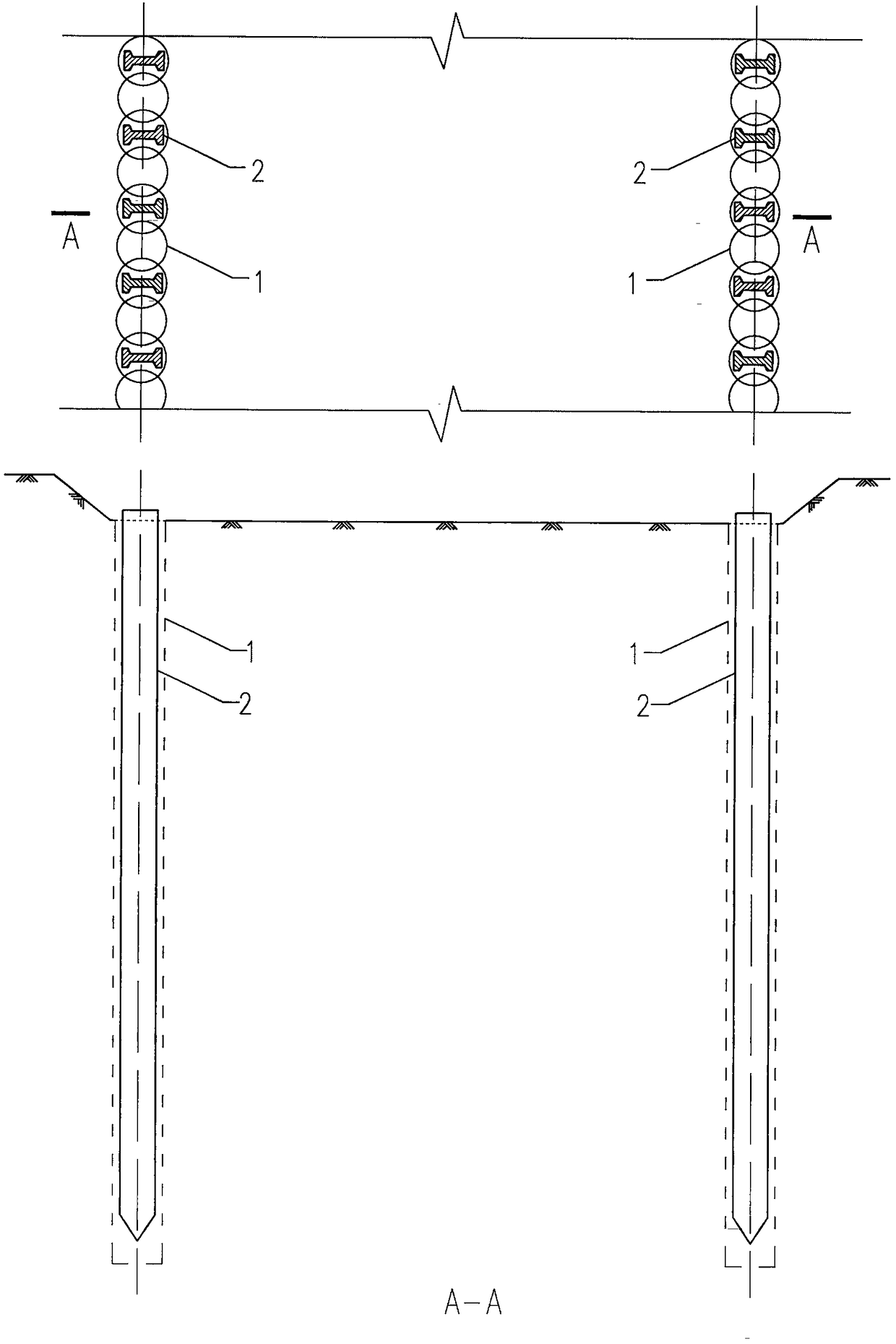

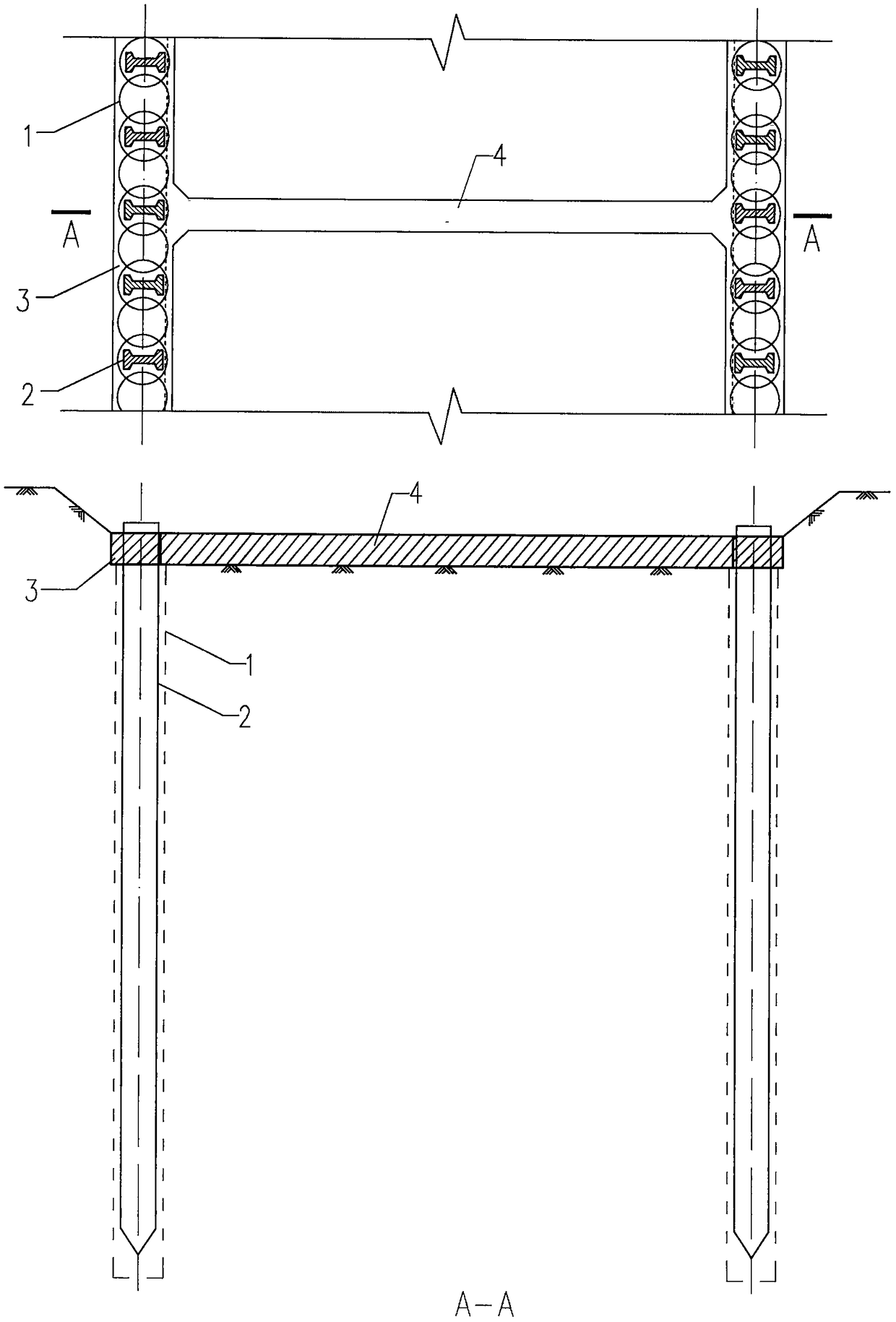

[0050] 1. First construct the retaining wall along both sides of the underground comprehensive pipe gallery. The retaining wall in the present invention adopts cement mixing pile 1 to implant prefabricated reinforced concrete I-shaped pile 2 to form (see attached Figure 2.1 ); it has the advantages of simple construction, fast speed, low cost and no mud transportation, and the retaining piles are also used as engineering anti-floating piles and engineering pressure piles of the underground pipe gallery structure, and can also be used as the outer wall of the underground pipe gallery Part of it bears the lateral water and soil pressure together with other structures of the underground pipe gallery.

[0051] Steel plate a is pre-embedded on the prefabricated reinforced concrete H-shaped pile 2, which is used to weld the force-transmitting steel c; in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com