Infrared two-point non-uniform calibrating method based on frame black body field diaphragm

A technology of non-uniformity correction and field diaphragm, which is applied in the field of infrared thermal imaging, and can solve problems such as affecting the normal operation of the system, target loss, and poor correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] The application of the present invention is described below in conjunction with examples, and a cooling type HgCdTe infrared thermal imager with a resolution of 320 × 240 has been tested. The presence of sex has seriously disturbed the observation field of view.

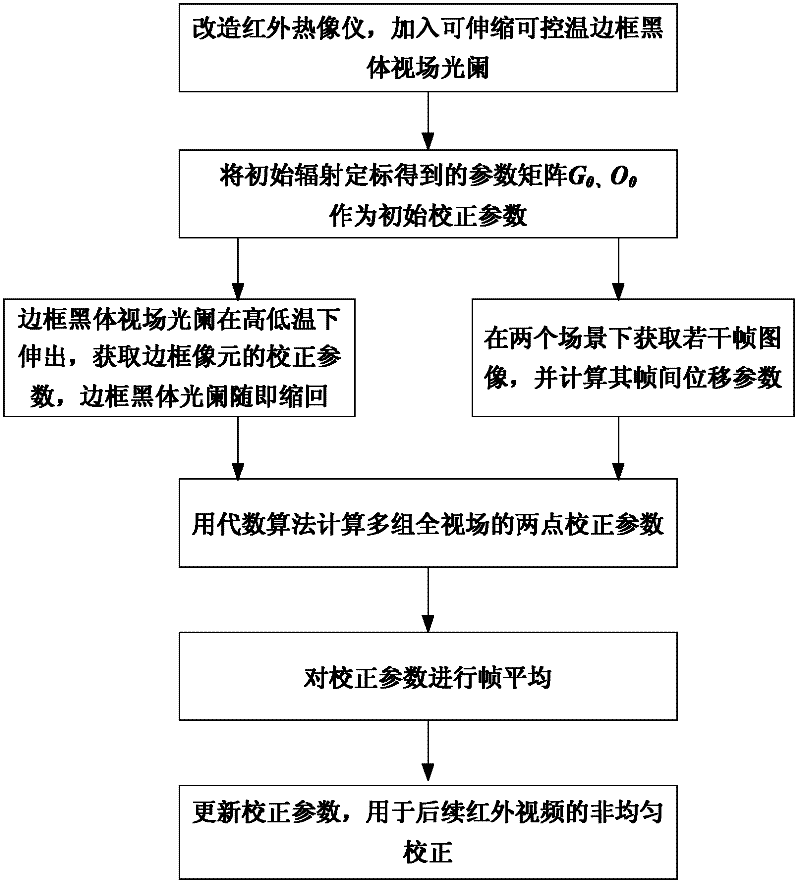

[0076] The update steps of IRFPA non-uniformity correction parameters based on frame black body are as follows: Figure 5 Shown:

[0077] S1. The parameter matrix G obtained by using the initial radiation calibration 0 , O 0 As a lookup table, as an initial calibration parameter;

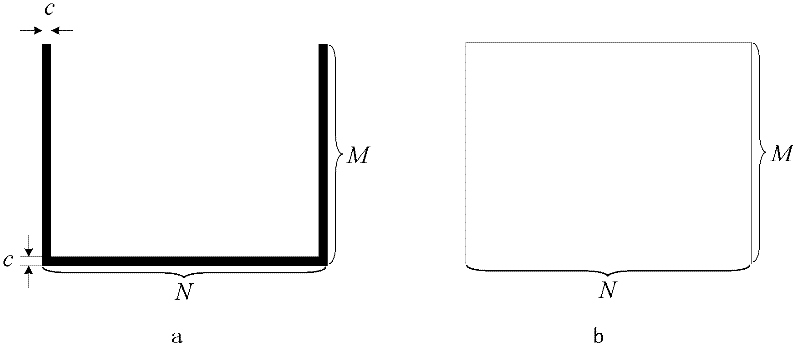

[0078] S2. The field diaphragm of the frame black body is stretched out at high and low temperature, and the gain correction parameters of the pixel field diaphragm under the frame black body are calculated with bias correction parameters The frame blackbody field diaphragm is then retracted, as figure 2 As shown, here, take the width of the border c=15;

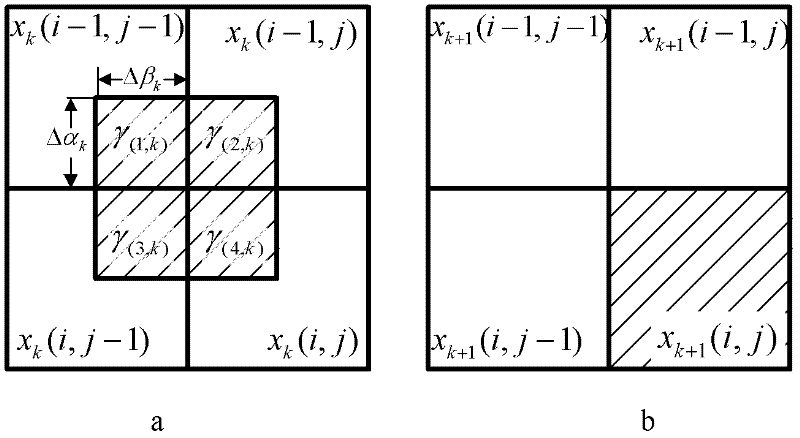

[0079] S3. Read in 20 frames of image data in each of the two scene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com