Method for detecting dehydration imbalance of inclined drum washing machine

The technology of a drum washing machine and a detection method is applied to the control device of the washing machine, other washing machines, washing devices, etc., which can solve the problems of unsatisfactory detection effect of the eccentric core, and achieve the effect of a high degree of intelligence and high-efficiency dehydration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

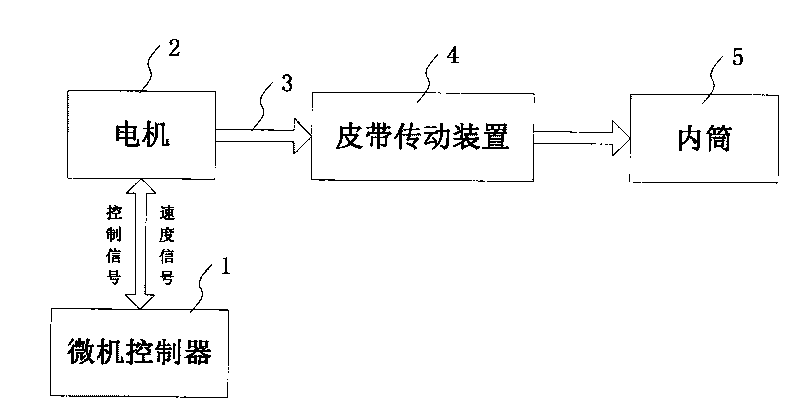

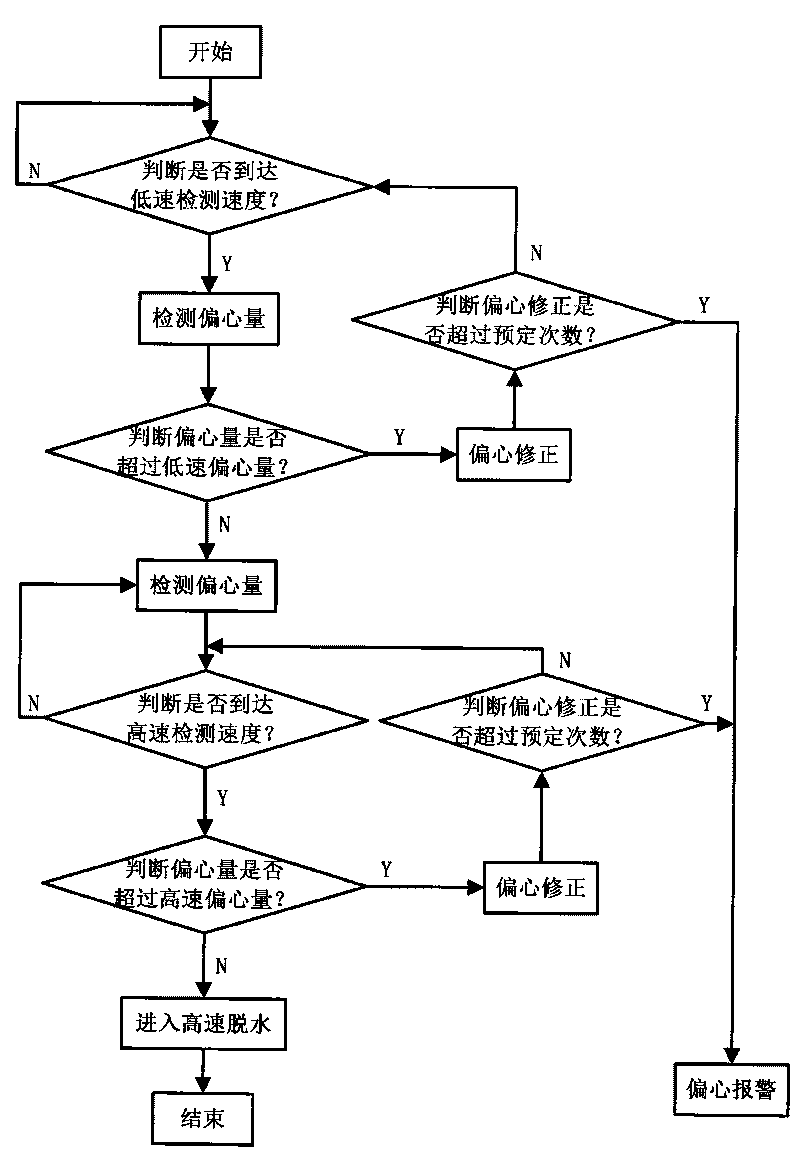

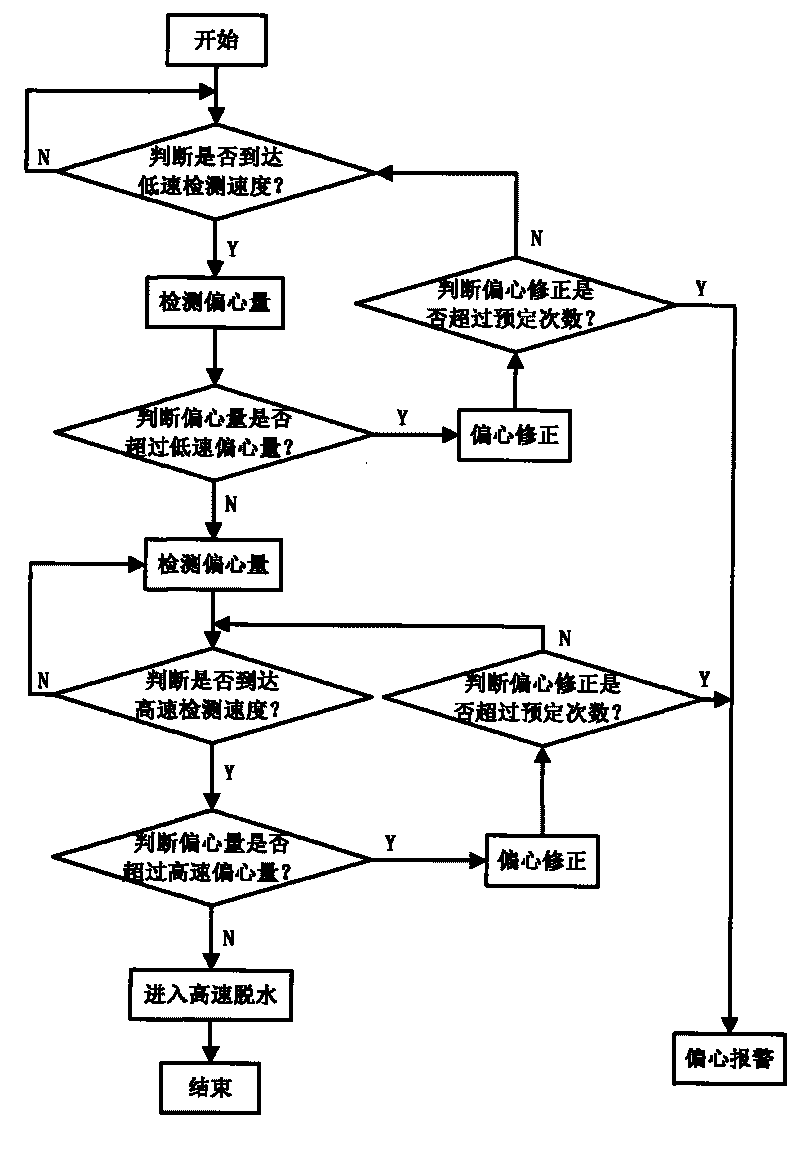

[0017] A method for detecting unbalanced dehydration of an inclined-drum washing machine. The method is divided into two speed sections, high speed and low speed, to detect the eccentricity: first, when the rotation speed of the inner cylinder 5 reaches the low speed detection speed, the eccentricity of the inner cylinder 5 is detected And judge whether the eccentricity exceeds the predetermined low-speed eccentricity, the low-speed eccentricity is 12rpm, if the judgment result is yes, then carry out eccentricity correction, otherwise continue to detect the eccentricity; When the speed is high, the eccentricity of the inner cylinder 5 is detected and it is judged whether the eccentricity exceeds the predetermined high-speed eccentricity. The low-speed eccentricity is 30 rpm. If the judgment result is yes, the eccentricity correction is performed; figure 1 , 2 As shown, after the eccentricity correction is performed, it is judged whether the number of eccentricity corrections e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com