Direct measurement method of engine exhaust gas recirculation (EGR) rate and engine EGR valve

A technology of EGR valve and measurement method, applied in engine components, engine control, combustion engine, etc., can solve problems such as affecting the performance of the whole vehicle, reducing the aperture, and reducing the combustion performance of gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

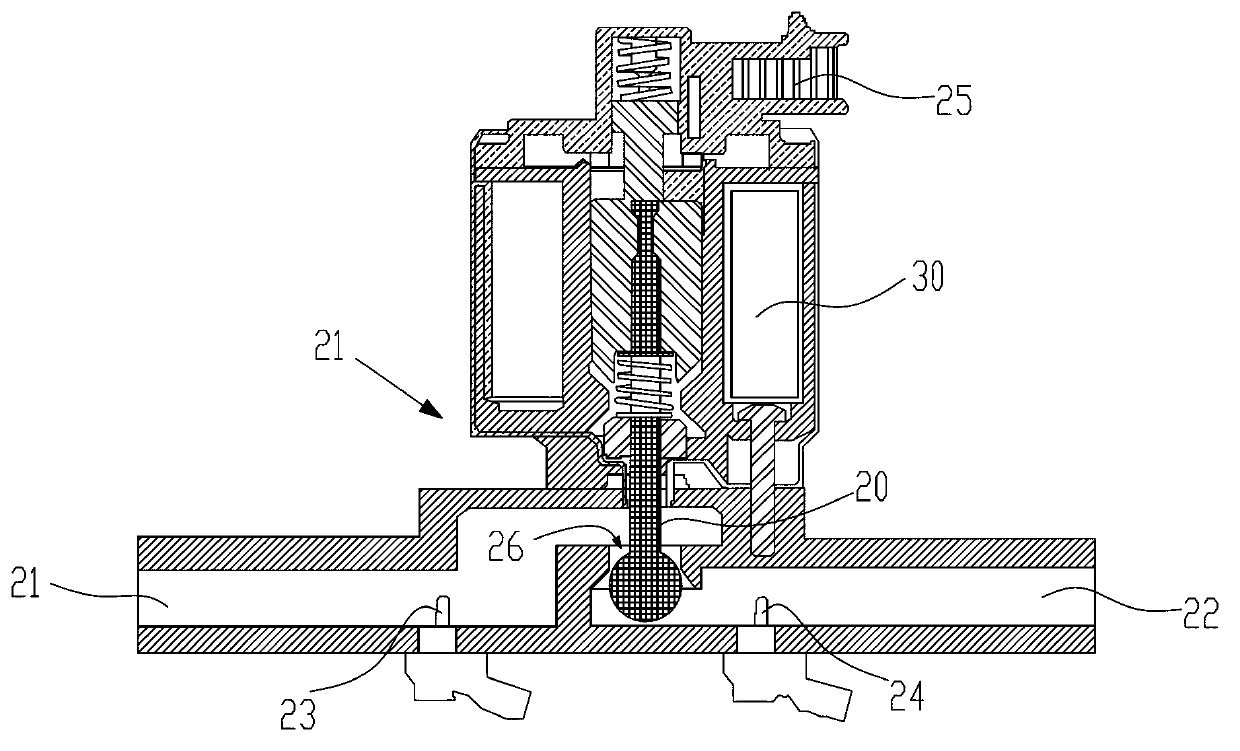

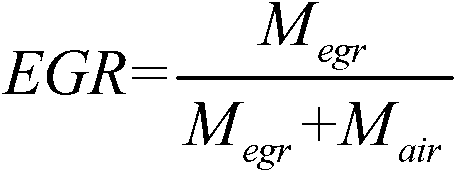

[0025] A method for directly measuring engine EGR rate, comprising the following steps:

[0026] a. Measure the fuel consumption meter and air-fuel ratio analyzer of the engine to obtain the fuel consumption of the engine B fuel and the excess air coefficient φ under the current working condition,

[0027] The mass flow M of the fresh air combusted in the engine cylinder is calculated according to the following relationship air :

[0028] m air =B fuel ×φ×14.5

[0029] b. Measure the pressure and temperature P of the exhaust gas inlet of the EGR valve a , T a and the pressure and temperature P of the exhaust port of the EGR valve b , T b ;

[0030] c. Measure the cross-sectional area A of the exhaust passage of the EGR valve o ;

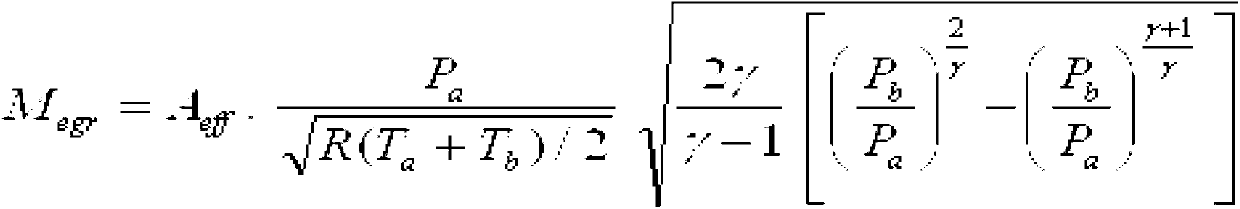

[0031] d. Calculate the exhaust gas mass flow rate M of the EGR valve according to the following relationship egr :

[0032] A eff =A o ×CFF

[0033] M egr = A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com