Experiment device and method for gas adsorption and desorption of large rock samples with different sizes

A technology of gas adsorption and experimental device, applied in the direction of analyzing materials and instruments, to achieve the effect of simple structure, saving experimental cost, and low cost of water bath heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

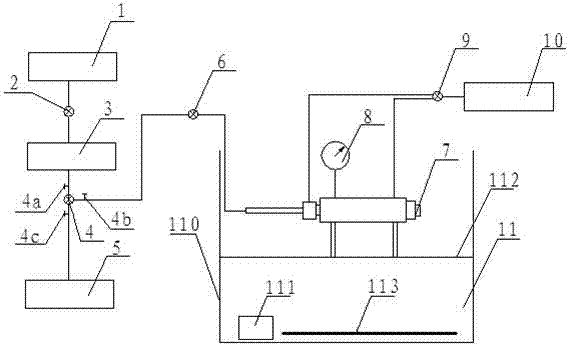

[0027] Embodiment 1: see figure 1 , gas adsorption and desorption experiment devices for large rock samples of different sizes, including a gas cylinder 1, a gas constant pressure device 3, a vacuum device 5, a core holder 7, a constant temperature heating device 11 and a metering pump 10.

[0028] The gas cylinder 1 communicates with the gas constant pressure device 3, and the gas constant pressure device 3 and the vacuum device 5 are combined and connected to a main pipeline through the three-way valve 4, and the main pipeline passes through the core holder inlet valve 6 and the core holder 7 The gas inlet is connected; the gas cylinder 1 is the gas source supply device of the experimental device, and during specific implementation, the gas cylinders can be multiple in parallel.

[0029] The rock core holder 7 is arranged in the constant temperature heating device; the constant temperature heating device preferably adopts a water bath constant temperature heating, and the sp...

Embodiment 2

[0036] Embodiment 2: a kind of experiment method that adopts the large rock sample gas adsorption and desorption experiment device of different sizes described in embodiment 1, specifically comprises the following steps:

[0037] S1: Put a core sample into the sample chamber of the core holder 7, apply a confining pressure and an axial pressure to the core sample by using a metering pump 10, and the axial pressure and the confining pressure are not less than 0.5 MPa of the gas pressure;

[0038] Check the airtightness of the device. After the airtightness meets the experimental requirements, close the pressure reducing valve 2 and the valve 4a of the gas constant pressure device, open the valve 4b of the sample chamber, the valve 4c of the vacuuming device and the inlet valve 6 of the core holder. Vacuumize the device so that the vacuum degree in the experimental device is not greater than -0.08MPa and lasts for not less than 4h;

[0039] Close sample chamber valve 4b, vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com