Calibration method and flow-rate measurement method for flow-rate controller of gas supplying apparatus

A technology of flow controller and gas supply, which is applied in flow control of electric devices, flow control, measurement flow/mass flow, etc. It can solve the problems of unavoidable flow calculation error and time-consuming volume V in the flow path, and achieve simple Effects of flow correction, rapid flow correction, and high-precision flow correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

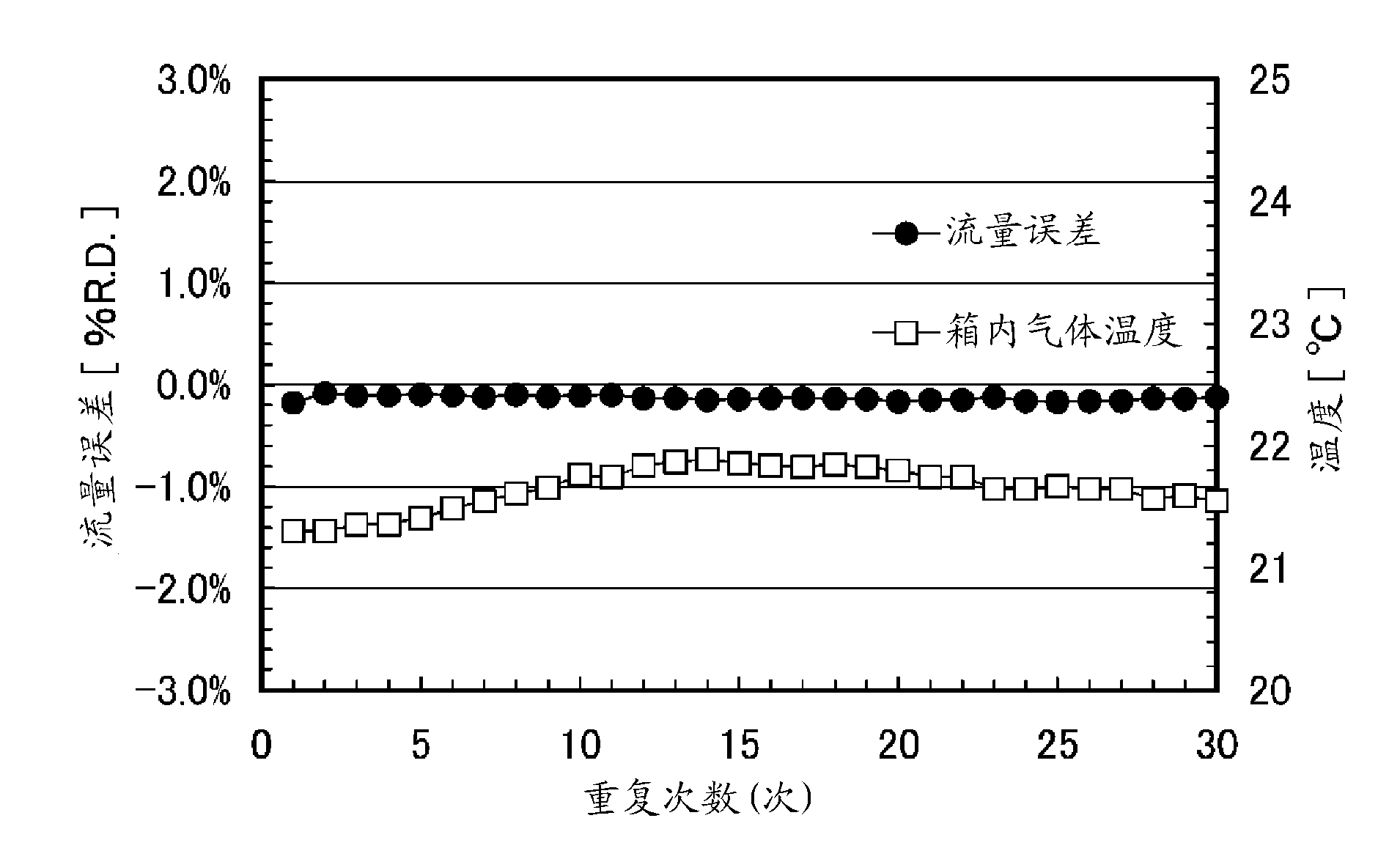

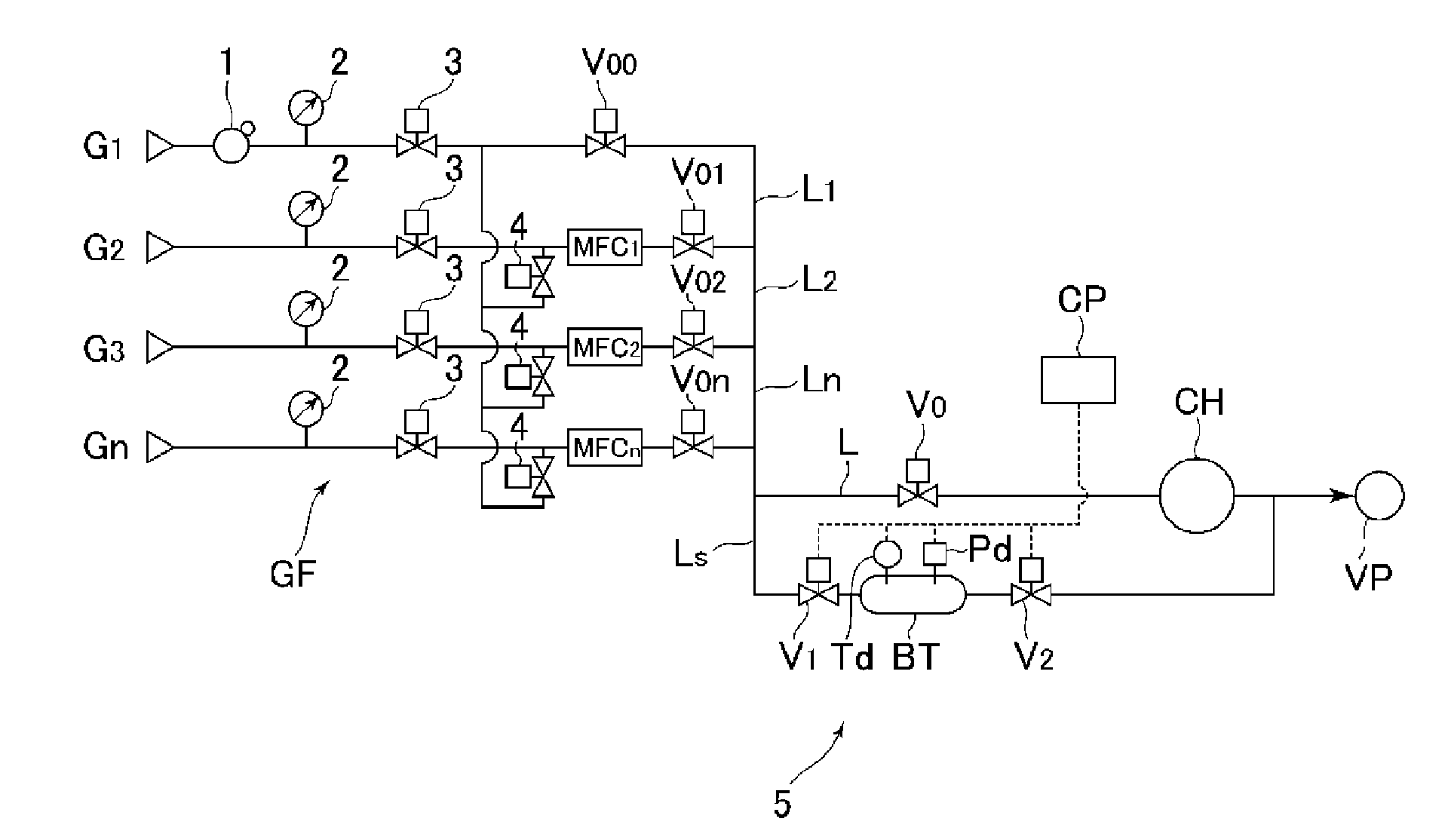

[0058] refer to figure 1 and figure 2 , when calibrating the flow rate of the flow controller of the gas supply device GF, the flow controller calibrating unit 5 is first connected to the gas supply line L in a branched form. Next, in the flow controller MFC 1 correction, will open and close the valve V 00 , V 02 , V 0n , V 0 Closed, open and close the valve V 01 , V 1 , V 2 Open, from flow controller MFC 1 The gas flow of the set flow rate Qs is supplied to the calibration unit 5 and exhausted by the vacuum pump VP.

[0059] Next, if the gas temperature To and the gas pressure Po in the accumulating tank BT of the calibration unit 5 are stabilized, the outlet side on-off valve V 2 It is closed to start accumulation of gas, and the gas temperature To and gas pressure Po in the box are detected and input to the calculation control unit CP.

[0060] Progress towards the accumulation of gas inside the tank BT, if the gas pressure reaches the set value P 1 (or set th...

no. 2 Embodiment approach

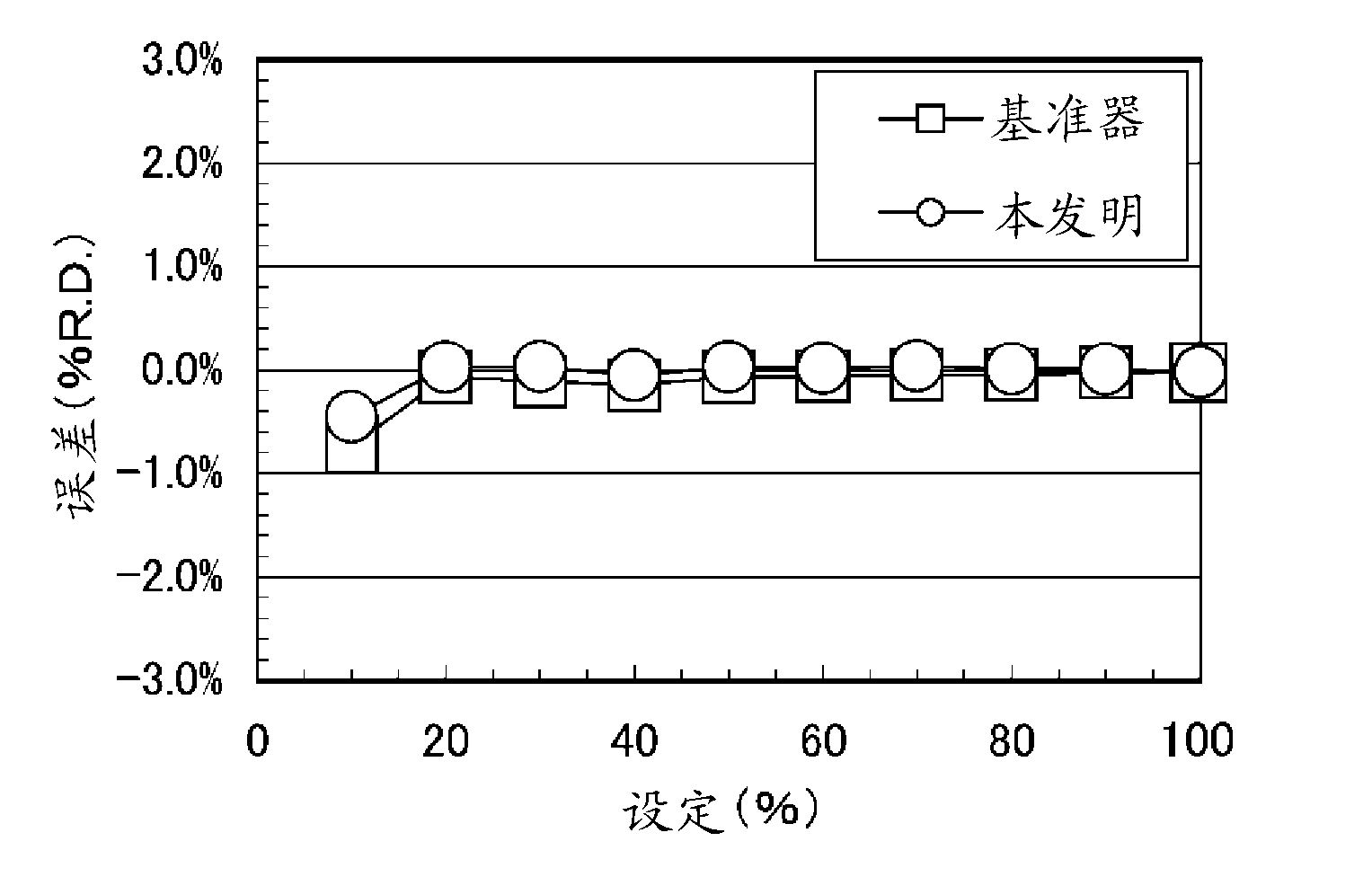

[0077] In the second embodiment, since the internal capacity of the accumulation tank BT is as small as 120.36 cc, first, the relationship between the supply flow rate and the tank internal pressure was investigated.

[0078] Figure 6 is a graph showing the results of this investigation, and Figure 7 yes Figure 6 A magnified view of part A.

[0079] Depend on Figure 6 and Figure 7 It can also be seen that when the internal volume of the accumulation tank BT is about 120.36cc, the gas supply flow rate is 1.6SLM, and the internal pressure rises to about 100Torr (opening and closing valve V 1 , V 2It is an on-off valve with a Cv value of 0.1). In addition, T1000 is a calibrated flow controller adjusted by the above-mentioned calibrated flow control equipment, etc.

[0080] On the other hand, there are thermal flow controllers or pressure flow controllers among flow controllers to be corrected, and in the case of pressure flow controllers, the pressure value on the out...

no. 3 Embodiment approach

[0100] Figure 11 It is a system diagram of the flow controller calibration unit used in the third embodiment of the present invention, T1000 is the calibrated flow controller adjusted by the calibrated flow control device, etc., ST is the waste chamber, and V 1 is the on-off valve on the inlet side of the accumulation tank BT, V 1S is the on-off valve on the inlet side of the waste chamber, V 2S It is the on-off valve on the outlet side of the waste chamber. In addition, of course, the inlet side on-off valve V 1 and V 1S Replaced with double three-way valve (two-connected three-way valve) V 3 And use.

[0101] In the flow calibration and flow measurement of the flow controller, it is necessary to keep the gas flowing for a certain period of time from the vacuum state to the flow, pressure, and temperature stabilization. It takes a long time until the gas is stable, and the gas flow is large. In the case where, for example, a gas with a flow rate of several LSM to sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com