Exhaust smoke passage integrated purification system for plurality of diesel engine test table frames

A technology of purification system and test bench, applied in exhaust treatment, exhaust device, internal combustion engine testing, etc., can solve problems such as difficulty in supporting centralized purification of exhaust flue, long flue gas main pipe, affecting NOx catalytic conversion efficiency, etc. Achieve the effect of strong technical sustainability and reduction of total particulate emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

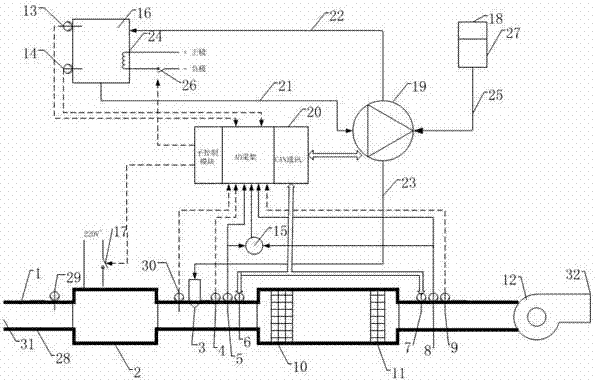

[0022] Such as figure 1 As shown, a flue gas purification system of a diesel engine test bench includes a flue gas constant temperature preheating system, a urea metering injection system, a urea aqueous solution storage system, a compressed air purification system, and a catalytic system; the flue gas constant temperature preheating system includes a large Power heater 2; the catalytic system includes a SCR catalytic converter 10 and a DOC catalytic converter 11; a first temperature sensor 29 and a high-power heater are sequentially installed on the flue gas main pipe 1 from the flue gas inlet end 31 to the outlet end 32 2. Second temperature sensor 30, nozzle 3, third temperature sensor 4, first NOx sensor 6, SCR catalytic converter 10, DOC catalytic converter 11, secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com