Method for measuring complicated type face flow area with supercritical pressure ratio

A flow area and supercritical technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of inability to accurately measure small and complex faces, poor versatility of measuring devices, and small measuring range, so as to eliminate air Limited compressibility, strong versatility, and few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

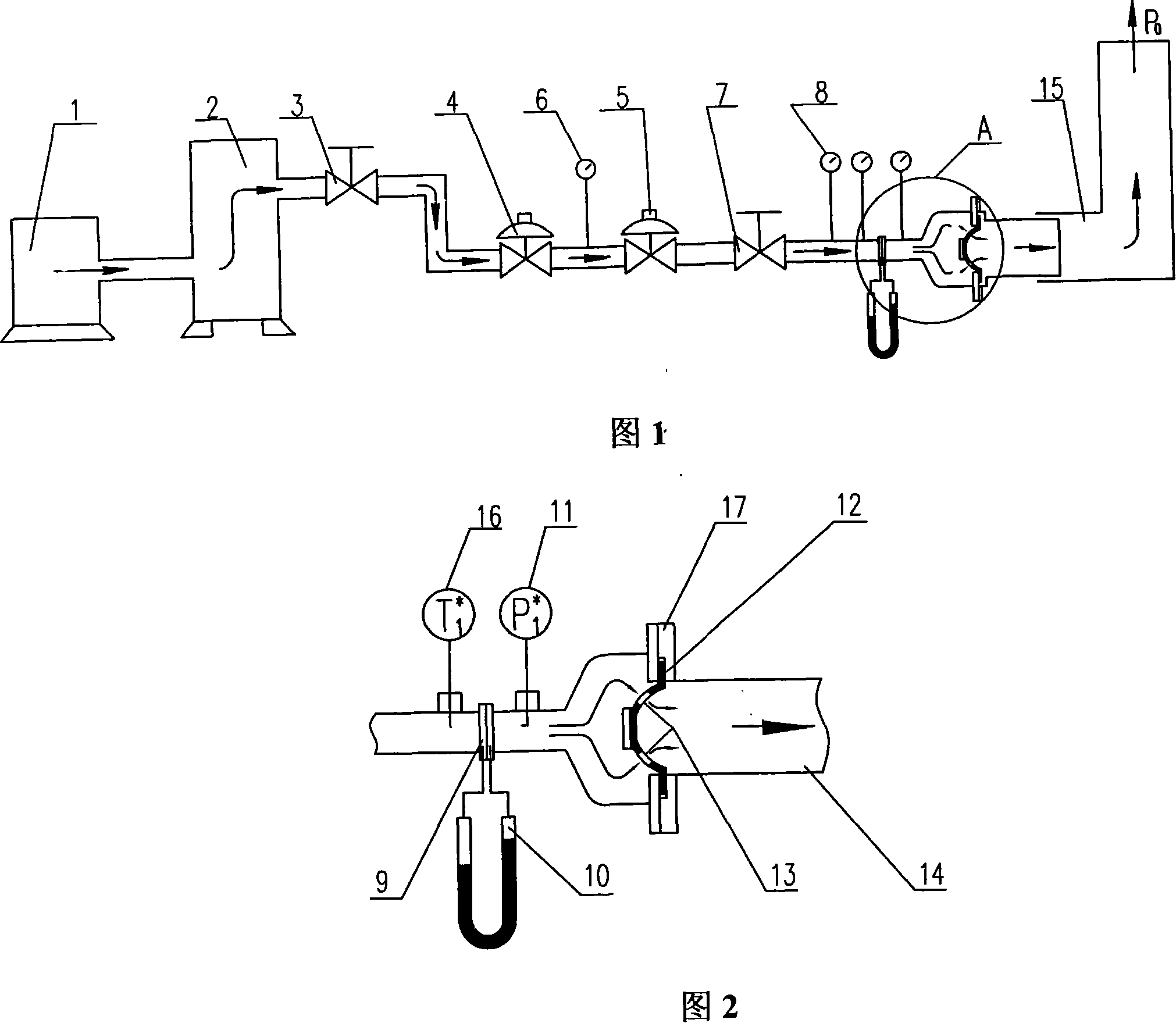

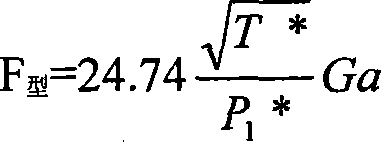

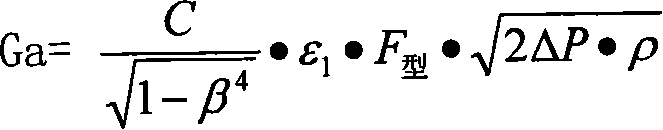

[0064] Install the measured part with a complex face in the measuring device in the manner shown in Figure 1 and Figure 2, fasten the measured part 12 with the mounting edge 17, and pay attention to not allowing air leakage. The compressed air enters the air storage tank 2 from the air source 1. Its function is to stabilize the air pressure and remove the moisture and impurities in the air. Then the air flow passes through the air source valve 3, enters the air pipeline and passes through the constant pressure reducing valve 4, Reduce the air pressure to the set value. The pressure gauge 6 displays the pressure behind the first-stage constant pressure relief valve, and then through the second stage constant pressure relief valve 5 and the regulating valve 7, the pressure gauge 11 in front of the measured part is accurately adjusted to the set value P1 * , while the temperature T of the airflow is displayed by the thermometer 16 1 * , The airflow passes through the throttle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com