Electricity generating device utilizing constant ultra-low concentration transportation, purification and supercharging of gas

An ultra-low concentration, power generation device technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of engine supercharged gas explosion, unsafe gas transmission, etc., to ensure the operation of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

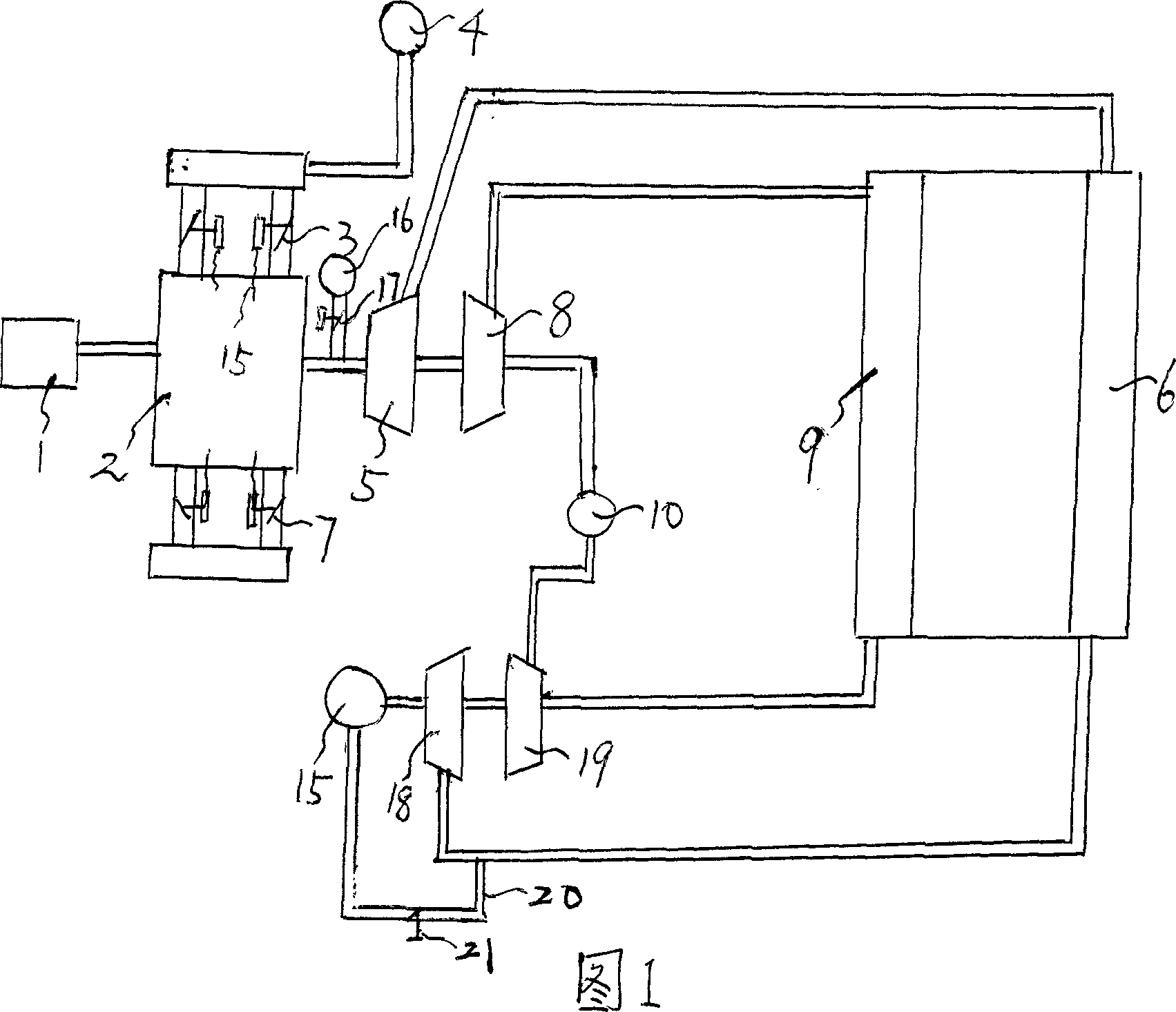

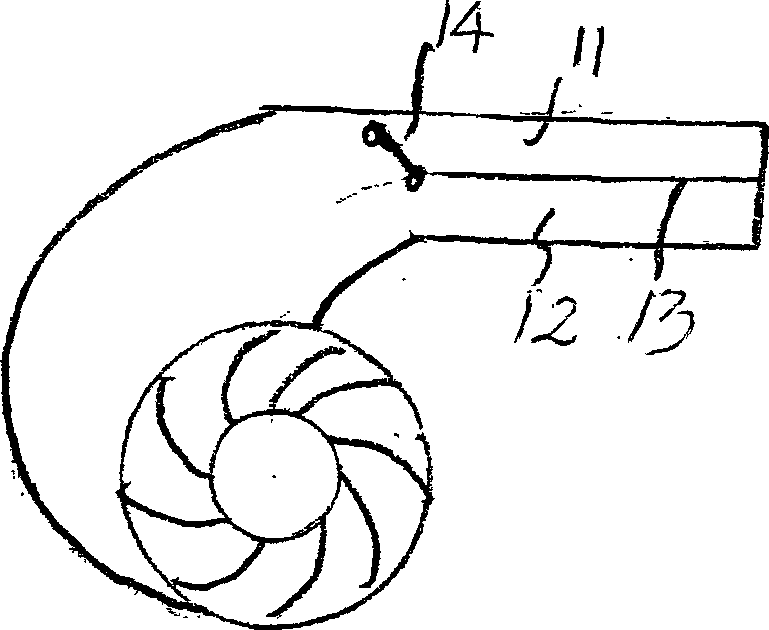

[0012] A gas constant ultra-low concentration transmission, purification and booster power generation device, including a gas constant ultra-low concentration tank 2 connected to a gas discharge port 1, and the gas constant ultra-low concentration tank 2 passes through an air suction control valve 3 and an air suction pipe 4 Connected, the gas outlet of the gas constant ultra-low concentration box 2 communicates with the compressor 5 of the dual-channel supercharger, and the upper channel 11 of the compressor 5 of the dual-channel supercharger communicates with the engine intake pipe 6, and the gas outlet of the dual-channel supercharger The lower channel 12 of the compressor 5 communicates with the gas constant ultra-low concentration tank 2 through the intake control valve 7 . The intake port of the dual-channel supercharger turbine 8 is connected to the engine exhaust pipe 9 , and the exhaust port of the dual-channel supercharger turbine is connected to the exhaust gas disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com