Method for measuring the actual porosity of the watertightness barrier of a fluid containment tank

A technology for sealing baffles and fluids, applied in the direction of measuring the acceleration and deceleration rate of fluids, testing of fluid tightness, methods of container discharge, etc., which can solve the problems of scarcity, reduction, and expensive stable cavity cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

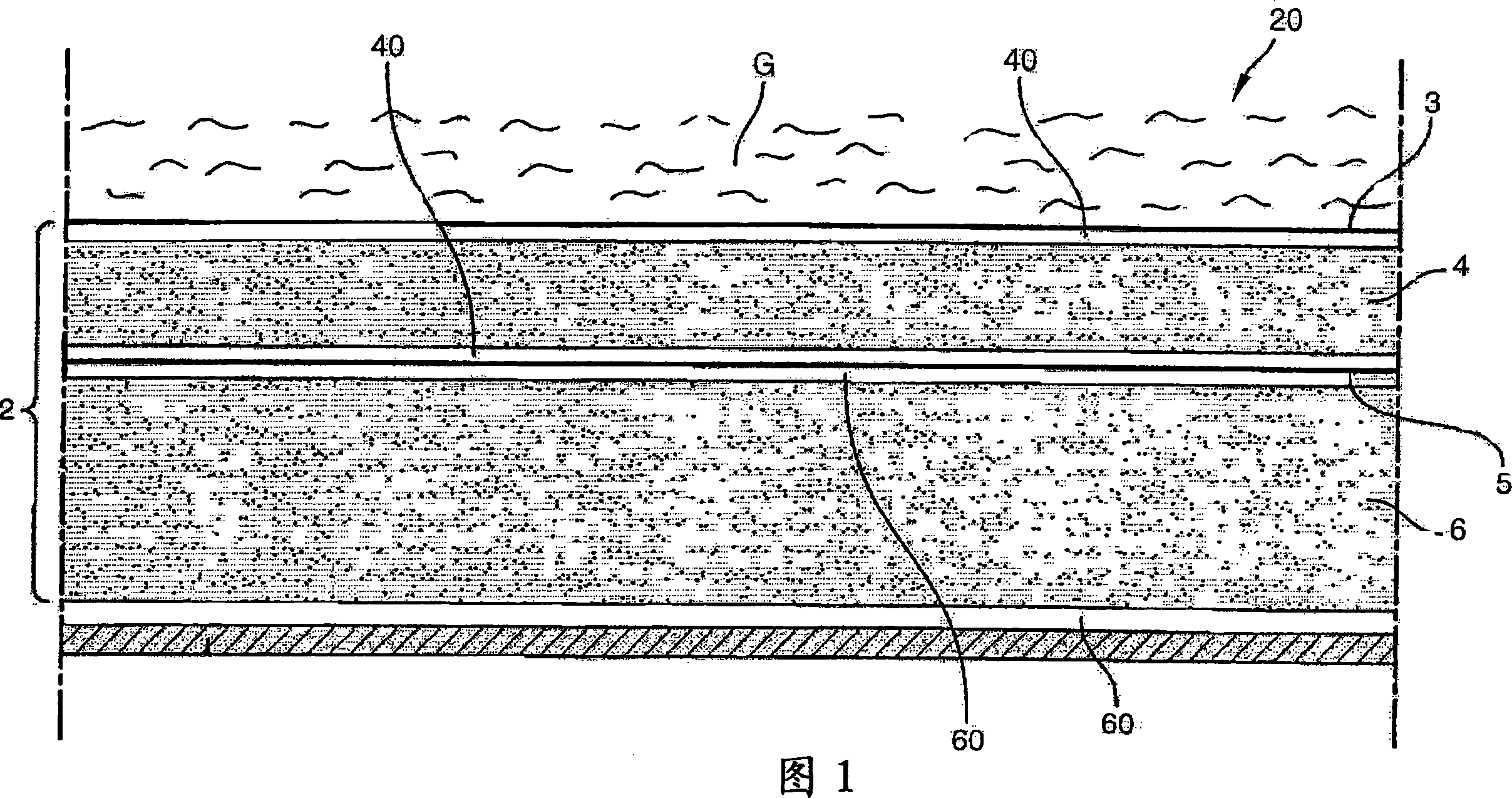

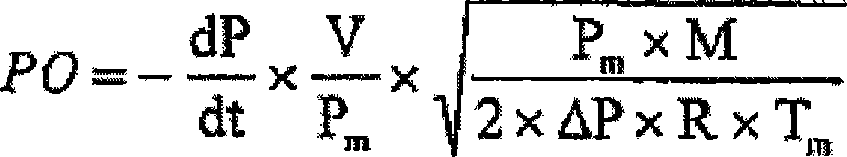

[0066] According to the invention, the air pressure in the free space 40 of the first thermal insulation layer 4 and in the free space 60 of the second thermal insulation layer 6 is adjusted according to the following criteria, whereby a stable range of measurements can be obtained, wherein the second thermal insulation layer can be carried out 6 different consistent measurements of air pressure and temperature in free space.

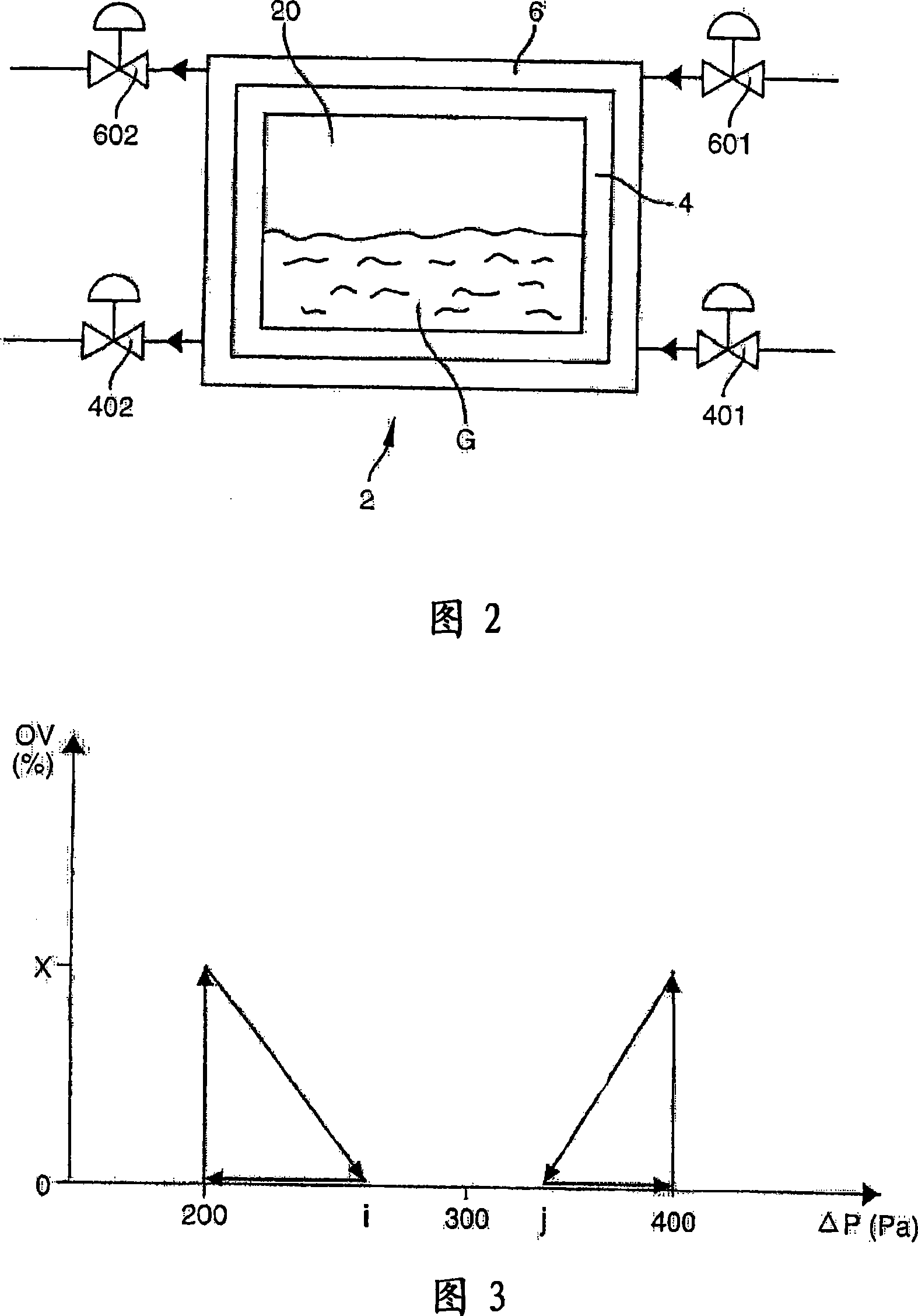

[0067] More specifically, the opening and closing of the supply valve 401, 601 and the discharge valve 402, 602 for the inert gas are controlled so as to maintain the air pressure in the free space 40 of the first heat insulating layer 4 at a value within the reference range, and The air pressure in the free space 60 of the second insulating layer 6 is kept at a difference ΔP from the air pressure in the free space of the first insulating layer 4 .

[0068] Preferably, the opening and closing of said valves 401, 601, 402 and 602 are controlled so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com