Simulation device of condensate gas constant volume depletion in dense porous medium and experiment method

A technology of porous medium and simulation device, which is applied in the field of condensate gas reservoir development experiment, can solve the problems of small oil drainage area of core section, small scale of condensate gas reservoir, differences in parameters, etc., and achieves reliable principle, great promotion value, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

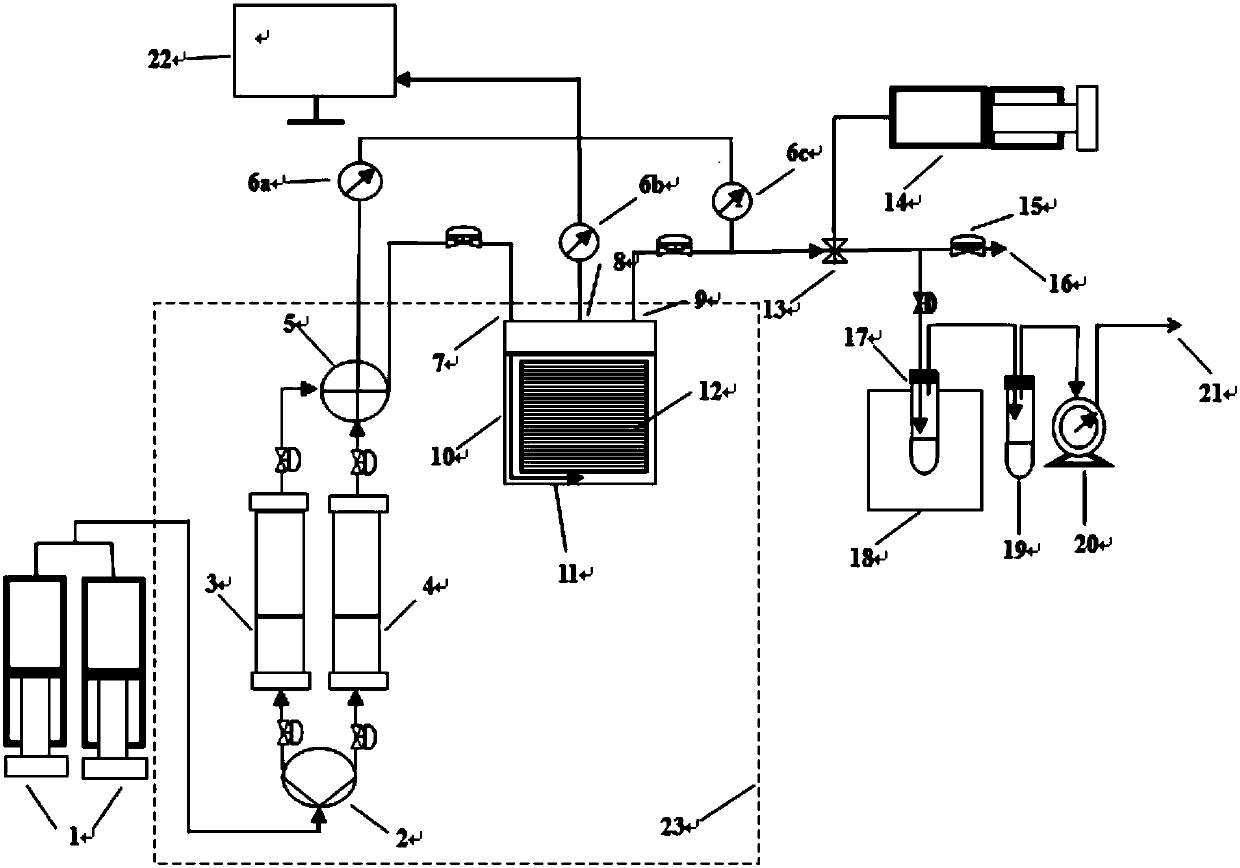

[0165] figure 1 A schematic structural diagram of a simulation device for constant volume depletion of condensate gas in dense porous media according to an exemplary embodiment of the present invention is shown.

[0166] Such as figure 1 As shown, a simulating device for constant volume depletion of condensate gas in dense porous media in this embodiment includes: a pressure supply module, a constant volume condensate gas reservoir module and an oil-gas separation module connected in sequence, wherein,

[0167] The constant volume condensate gas reservoir module includes a constant volume full diameter kettle 10, a first connecting pipeline 11 and a second connecting pipeline, the rock core 12 to be tested is arranged in the constant volume full diameter kettle 10, and the upper end cover of the constant volume full diameter kettle 10 An inlet hole 7, an outlet hole 9 and a pressure monitoring hole 8 are provided, and a first connecting pipeline 11 is used to connect the inle...

Embodiment 2

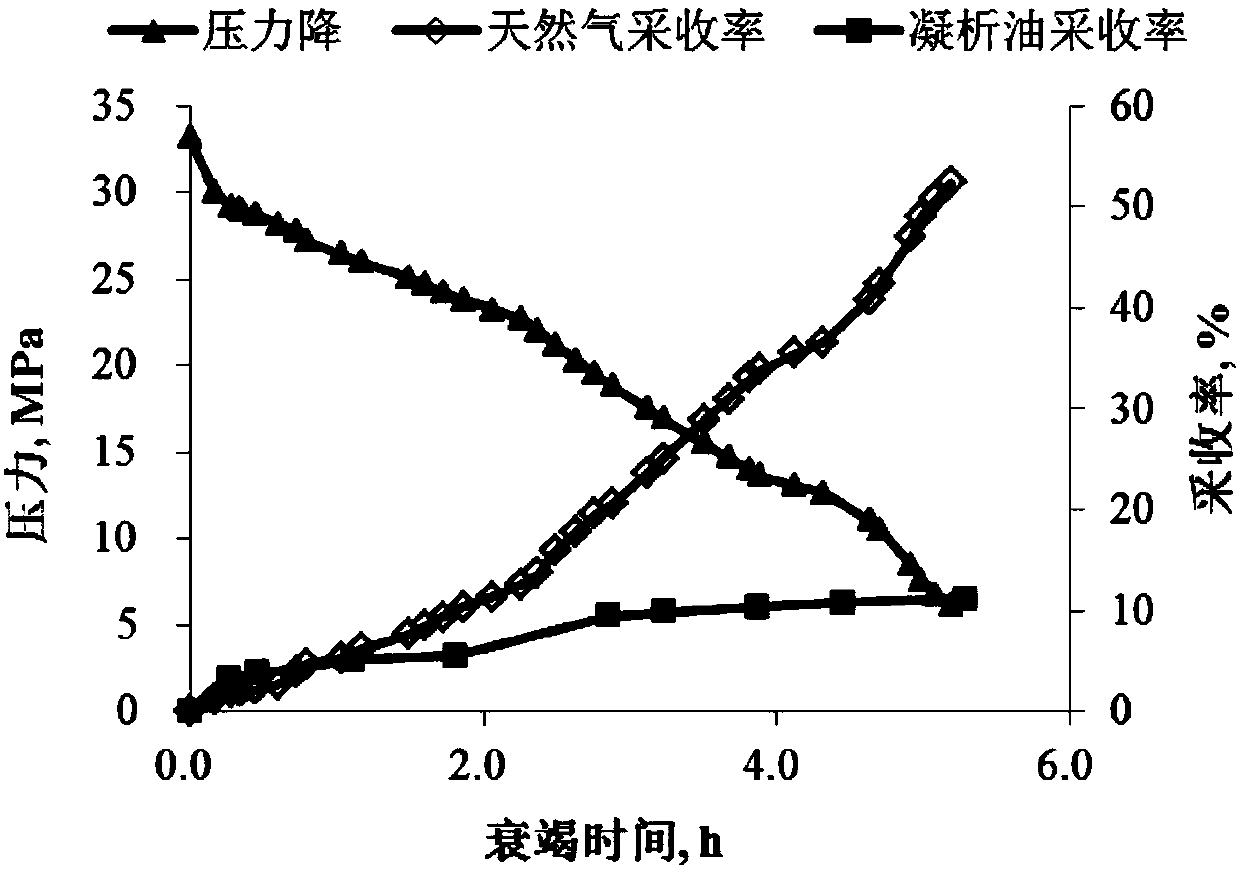

[0190] Example 2 is to carry out simulation development of condensate gas constant volume depletion in tight porous media for a condensate gas reservoir in China. The original formation pressure of the target layer is 31.4MPa, corresponding to the well depth temperature of 110.4°C, and there are fractures of different sizes around the gas well. According to the conventional PVT fluid phase state test report, it can be known that the dew point pressure of condensate gas under formation temperature and pressure is 26.23MPa. Based on the above data, a simulation test was carried out with the simulation device of Example 1.

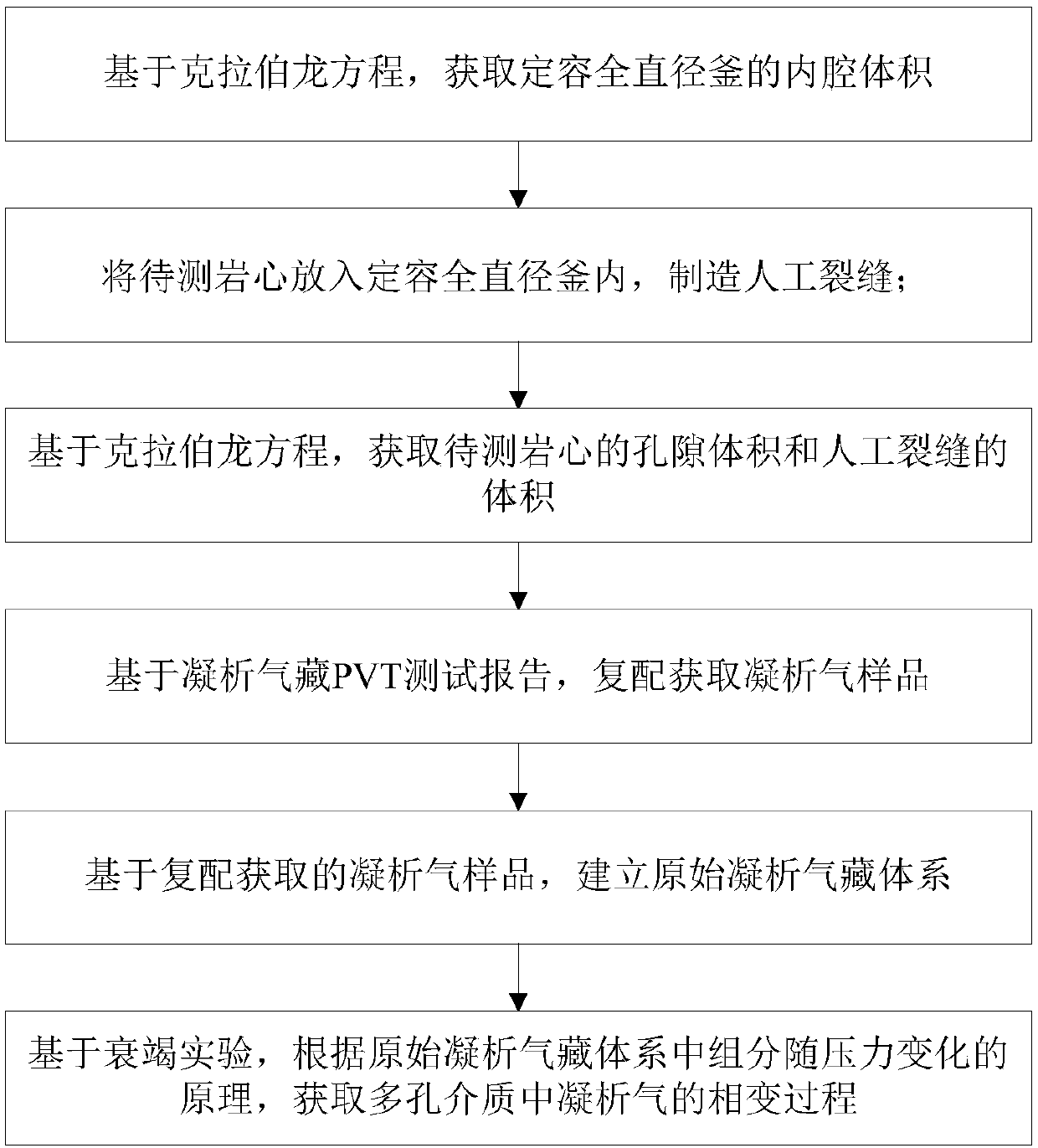

[0191] figure 2 A flow chart showing the steps of an experimental method for constant volume depletion of condensate gas in dense porous media according to an exemplary embodiment of the present invention.

[0192] Such as figure 2 As shown, the experimental method of constant volume depletion of condensate gas in a dense porous medium of the present embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com