V-shaped multi-cylinder aerodynamic engine

An aerodynamic and engine technology, applied in engine components, variable capacity engines, machines/engines, etc., can solve problems such as limiting the total output power of the engine and low total output power of an inline multi-cylinder aerodynamic engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

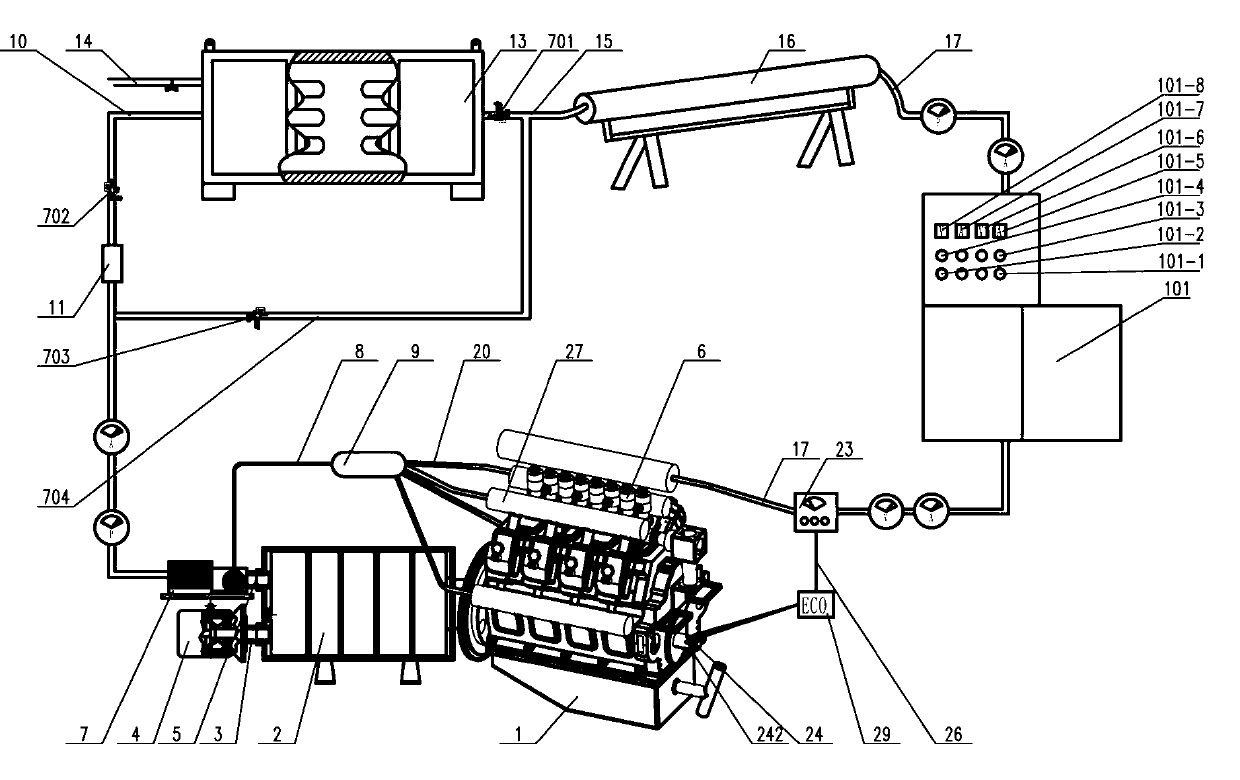

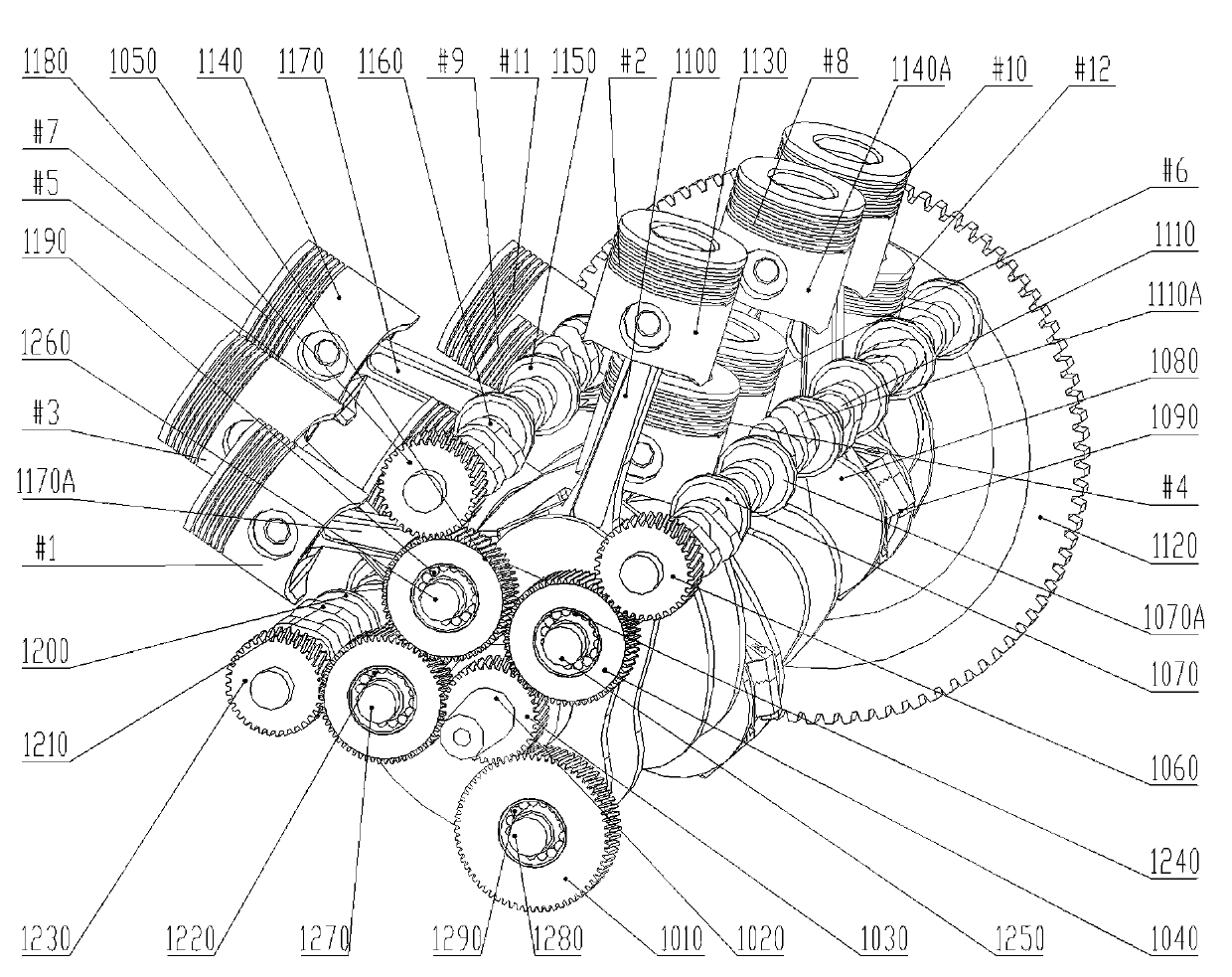

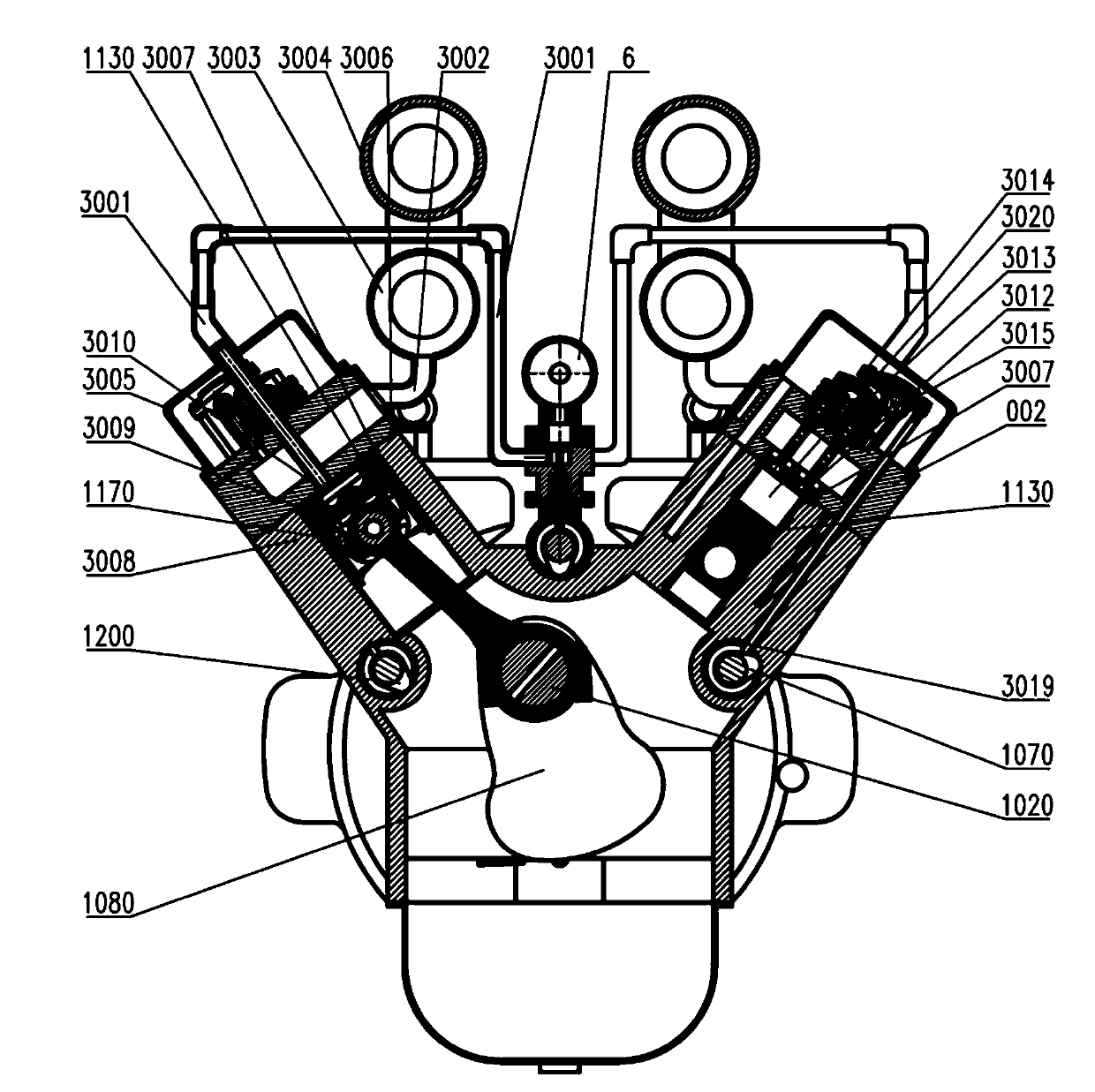

[0037] now refer to figure 1 , figure 1 It is an overall schematic diagram of a V-type multi-cylinder aerodynamic engine according to the present invention. exist figure 1 Among them, the V-shaped multi-cylinder aerodynamic engine includes engine body 1, multi-cylinder power distributor 2, power equipment 4, controller system 6, air compressor 7, condenser 11, exhaust gas recovery tank 9, and high-pressure gas tank group 13 , constant pressure tank 16, compressed air heating device 101, air intake control speed control valve 23, electronic control unit ECU 29, pressure limiting valve 702, sequence valve 703. like figure 1 As shown, the high-pressure gas tank group 13 is connected to an external gas filling stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com