Self-aligning roller bearing suitable for axial and radial unbalance loading working conditions and heat treatment process

A self-aligning roller bearing and roller technology, which is used in heat treatment furnaces, shafts and bearings, heat treatment equipment, etc., can solve the problem of uneven loading of two rows of rollers and corresponding raceways, and fatigue spalling of bearing rollers and raceways. , the overall life of the bearing is shortened, etc., to achieve the effect of high hardness, uniform contact stress, and reduced bearing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0038] It should be noted that many specific details are set forth in the following description to facilitate a full understanding of the present invention, however, the present invention can also be implemented in other ways than those described here. Therefore, the protection scope of the present invention is not limited by the specific embodiments disclosed below.

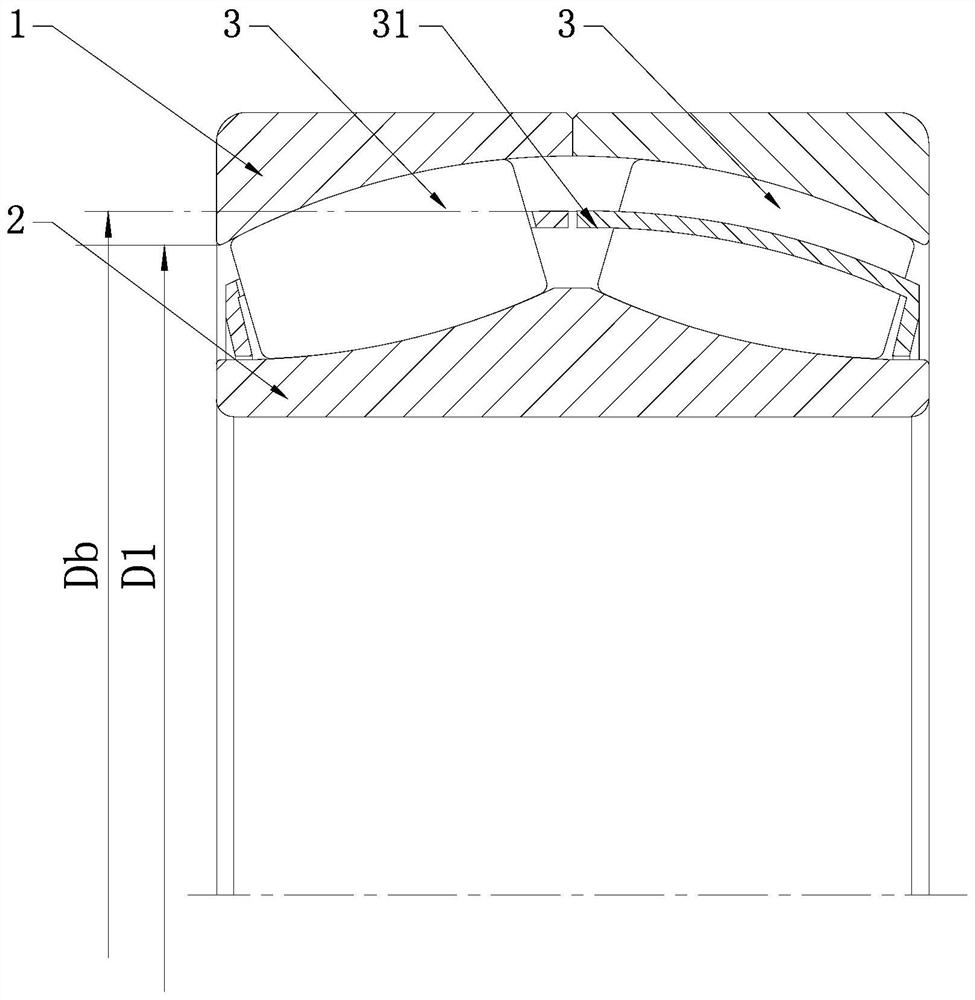

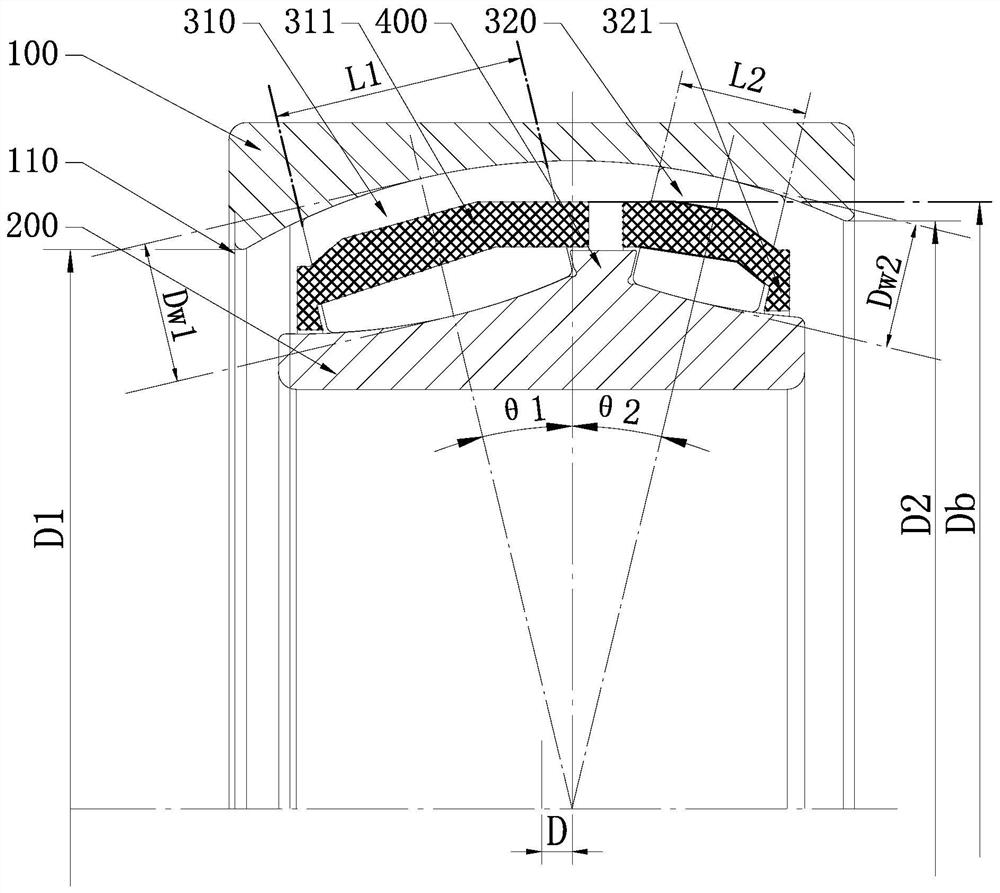

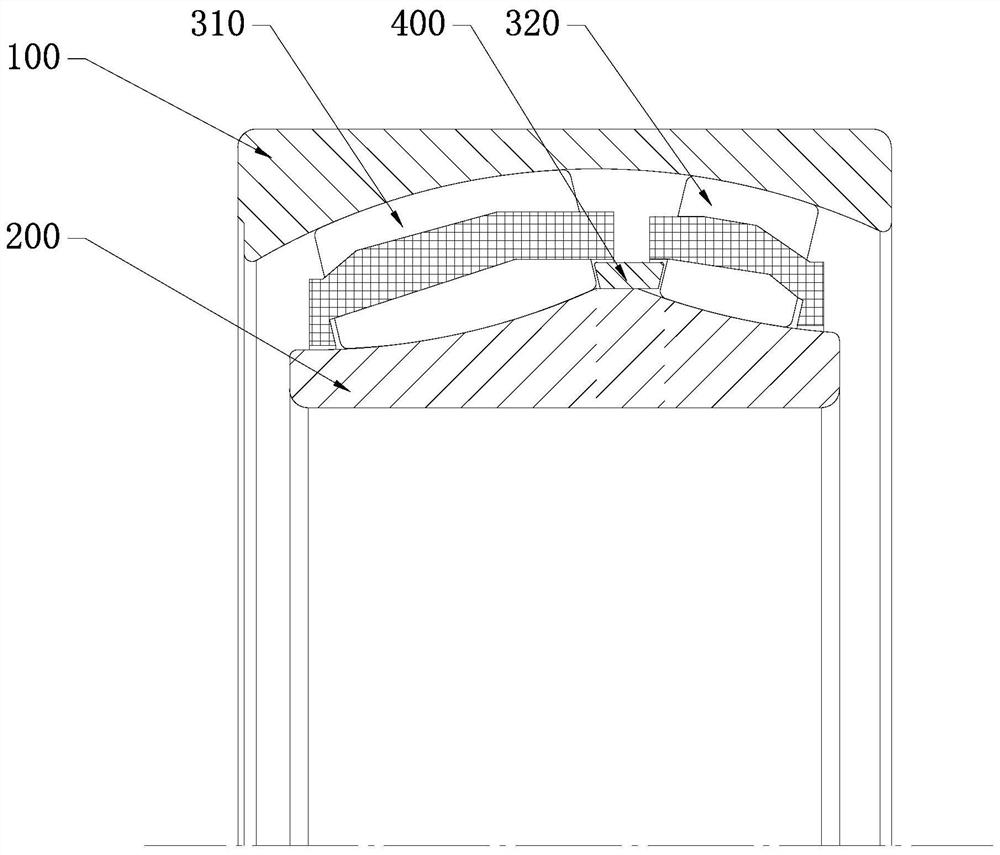

[0039] On the one hand, if figure 2 As shown in , the present invention provides a spherical roller bearing suitable for axial and radial eccentric load conditions, including an outer ring 100, an inner ring 200, and a cage held between the outer ring 100 and the inner ring 200 Two rows of symmetrical spherical rollers. It can be understood that the spherical roller means that the rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com