Coarse slime interference bed separation equipment based on gravity force and interfacial force, method and uses thereof

A technology that interferes with bed and interfacial forces, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of small adaptable range of feed particle size and poor sorting effect, and achieve large adaptable range and high sorting accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

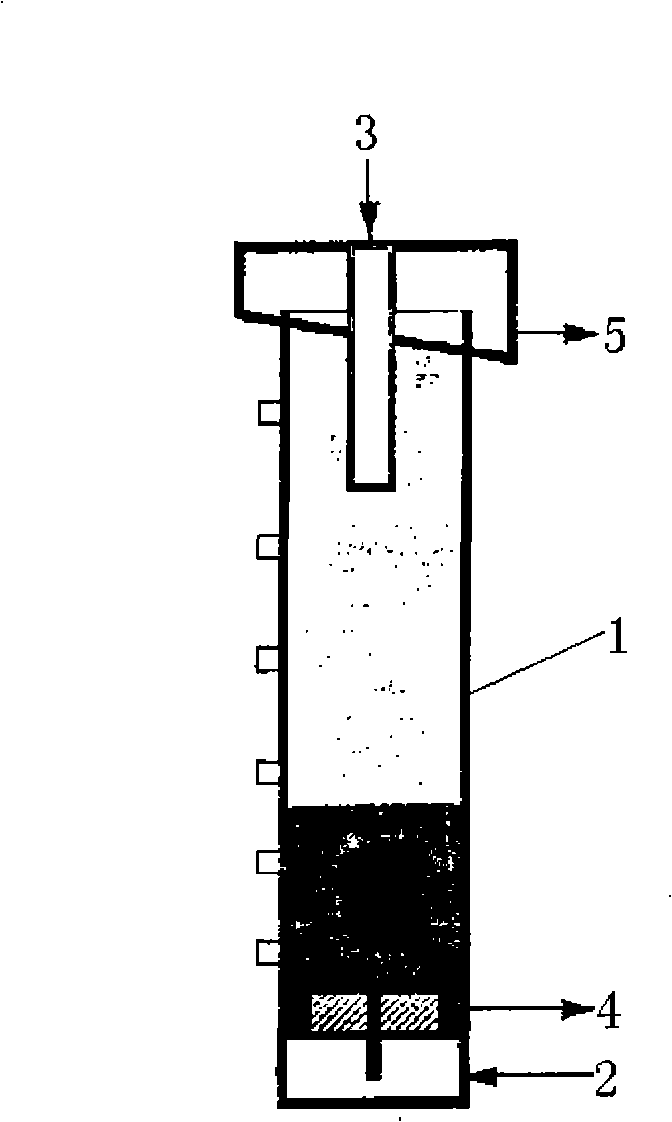

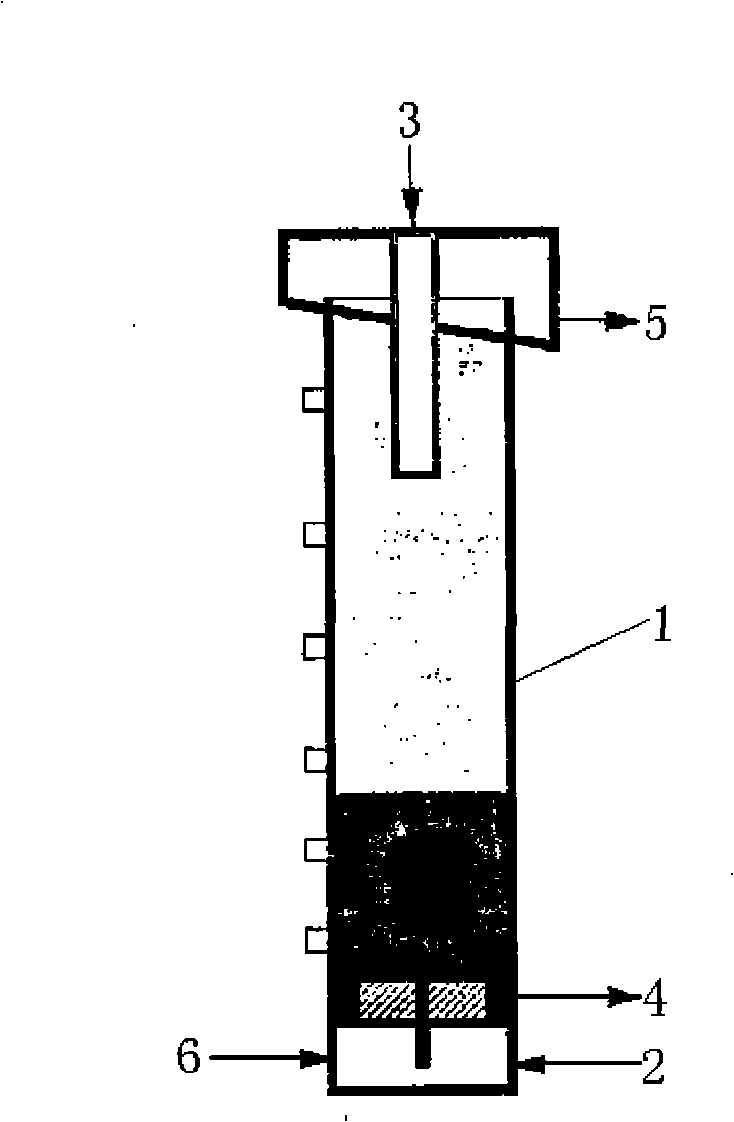

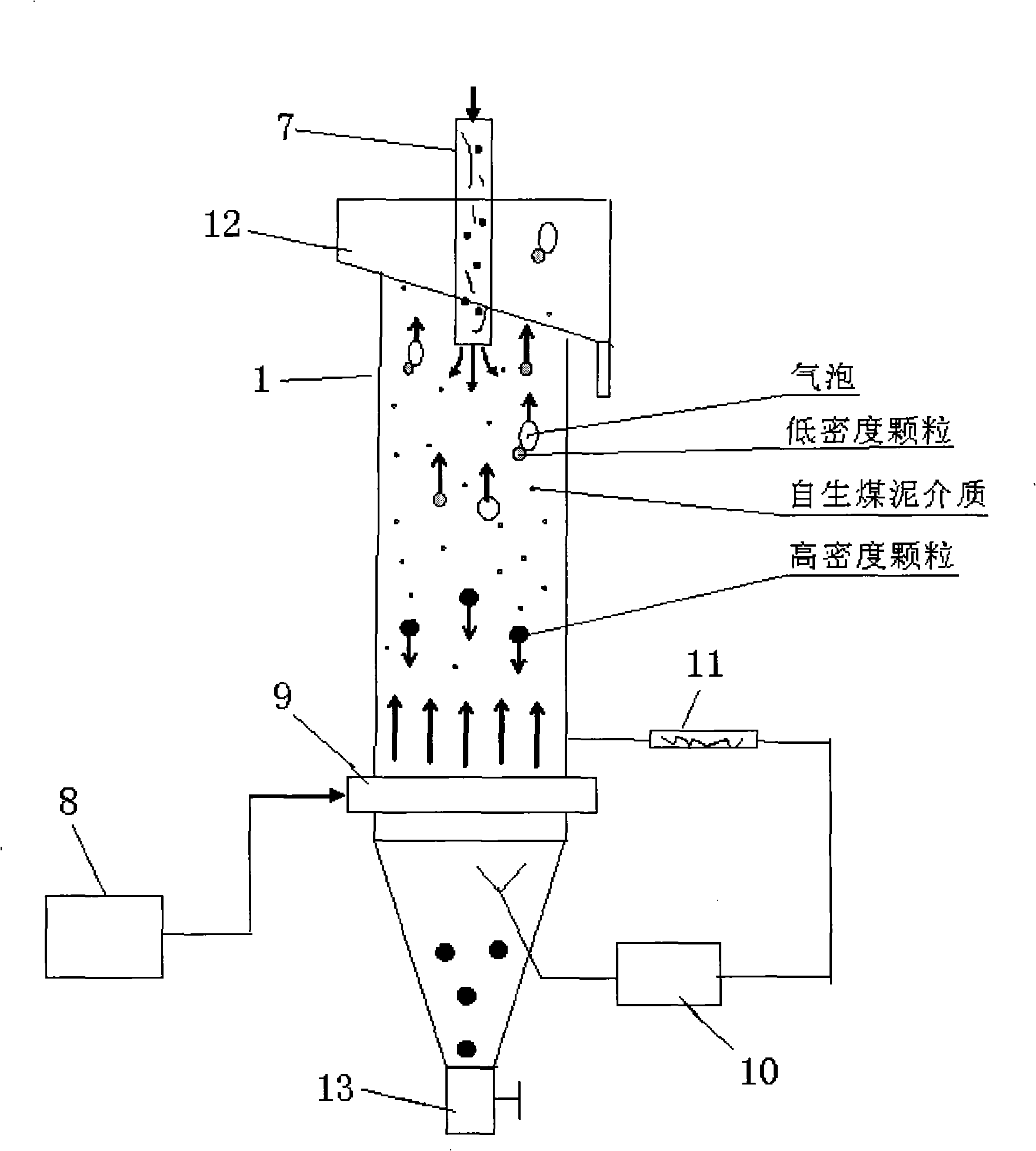

[0018] The coal slime disturbed bed sorting equipment based on gravity and interface force of the present invention, its preferred embodiment is as follows figure 2 As shown, it includes the main body 1 of the disturbing bed separator. The lower part of the main body 1 of the disturbing bed separator is provided with a water inlet 2 and an underflow port 4 , and the upper part is provided with a feeding port 3 and an overflow port 5 . The interference bed separator is a water medium interference bed separator.

[0019] The lower part of the main body 1 of the interfering bed separator is also provided with an air inlet 6 for introducing air into the rising water flow to separate the coarse coal slime.

[0020] The air inlet 6 can be connected with a bubble generating device, which is used to make the air into bubbles before adding them into the water flow.

[0021] The bubble generating device may include a circulating pump, a bubble generator, etc. Part of the middle ore in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com