Electrohydraulic energy-regenerative type shock absorber

A technology of shock absorbers and accumulators, applied in the directions of liquid shock absorbers, electric components, electromechanical devices, etc., can solve the problems of low efficiency of the energy feeding system, inability to apply to practical applications, shortening the life of generators, etc. The effect of energy recovery efficiency, fewer parts, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

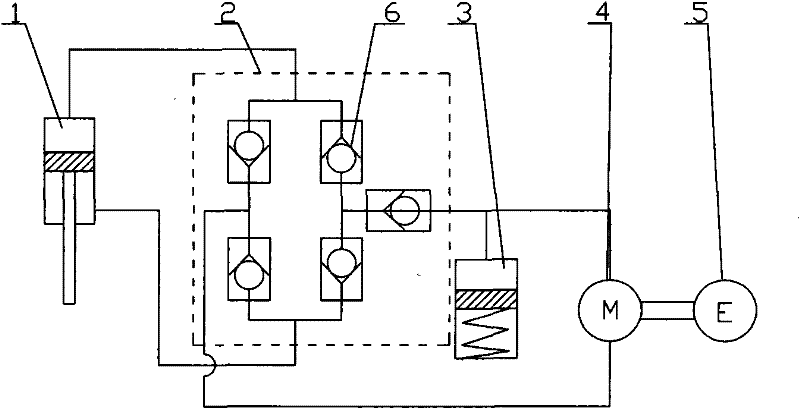

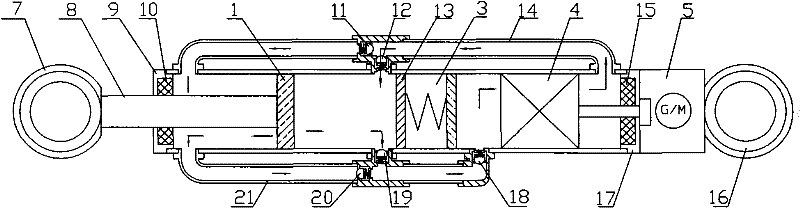

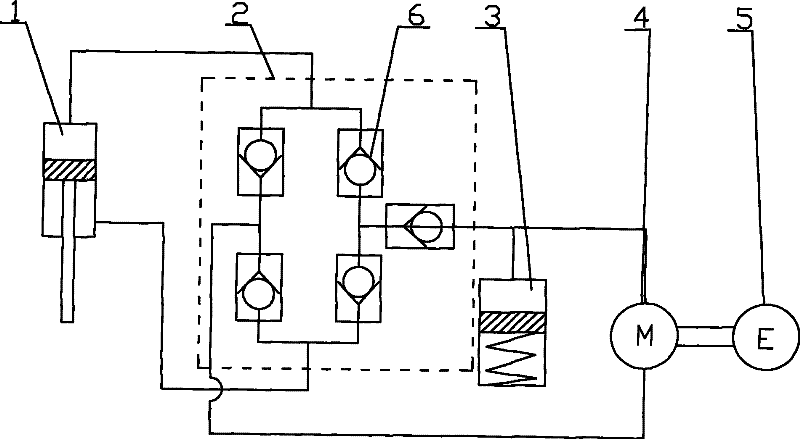

[0022] The invention provides a hydraulic-electric energy-fed shock absorber applied in the technical field of vehicles. It adopts an electromechanical-hydraulic hybrid system, and its working principle is to convert the relative linear motion of the sprung mass and the unsprung mass caused by the unevenness of the ground into a direction-invariant hydraulic flow to drive the hydraulic motor to rotate through the hydraulic rectifier bridge. The hydraulic motor drives the generator to generate electricity, so that the vibration mechanical energy is converted into electrical energy for recovery. Its basic structure is as figure 1 As shown: it mainly includes piston 1, hydraulic rectifier bridge 2, accumulator 3, hydraulic motor 4 and rotary generator 5. When the car vibrates, the piston converts mechanical energy into hydraulic energy by doing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com