Dual-motor rotating speed coupling drive assembly

A drive assembly, dual motor technology, applied in the direction of electric power unit, power unit, control device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

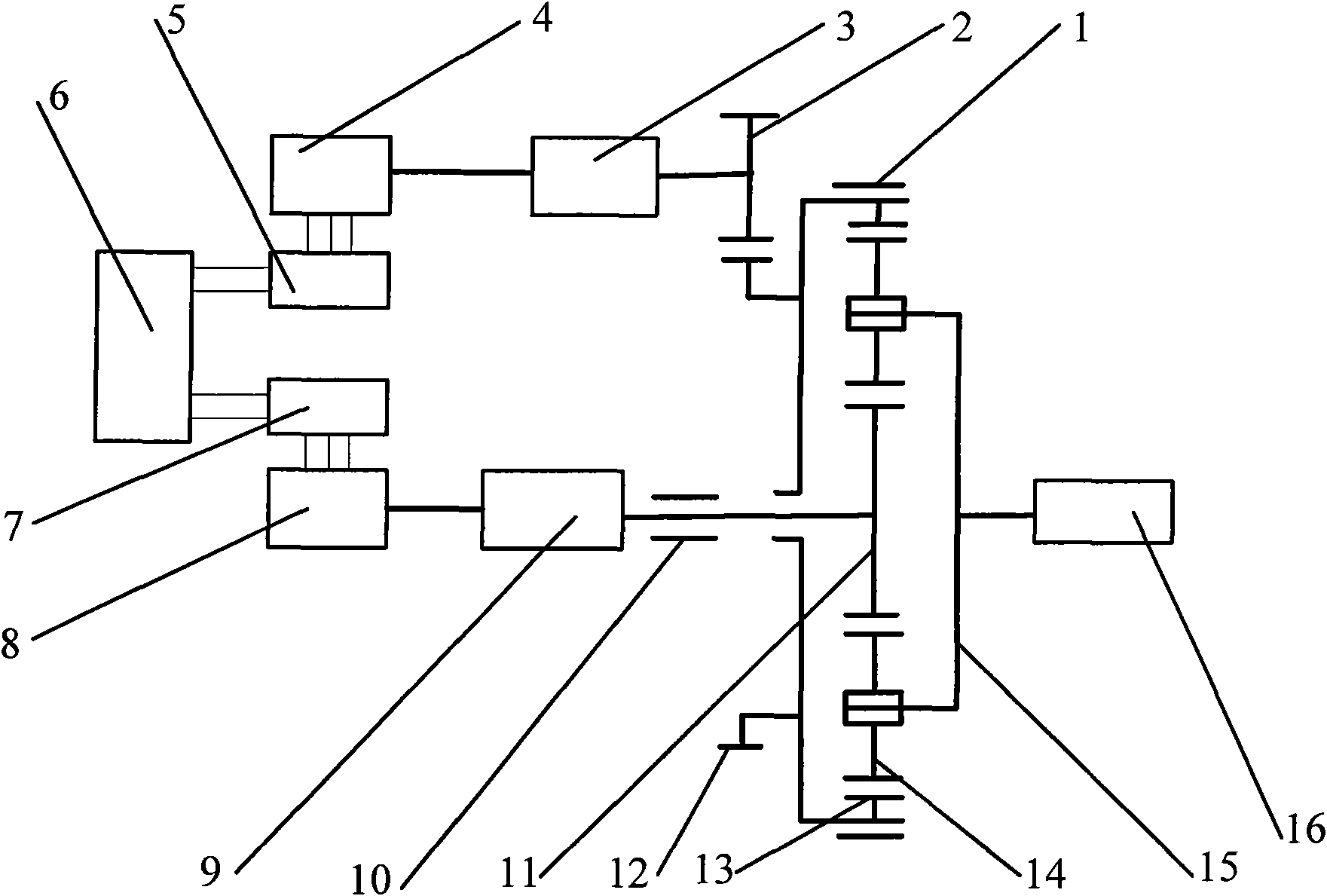

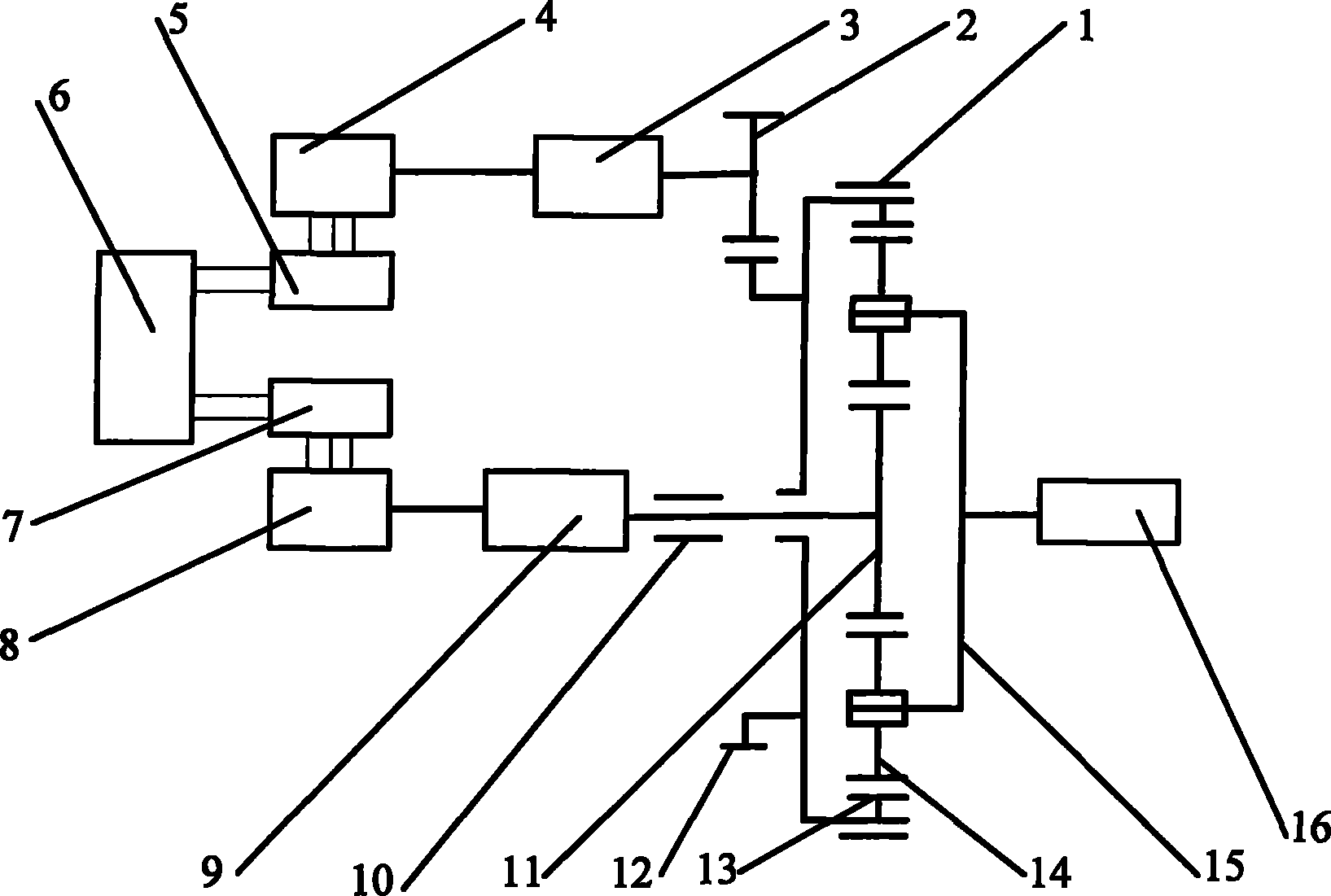

[0008] Now further illustrate in conjunction with accompanying drawing.

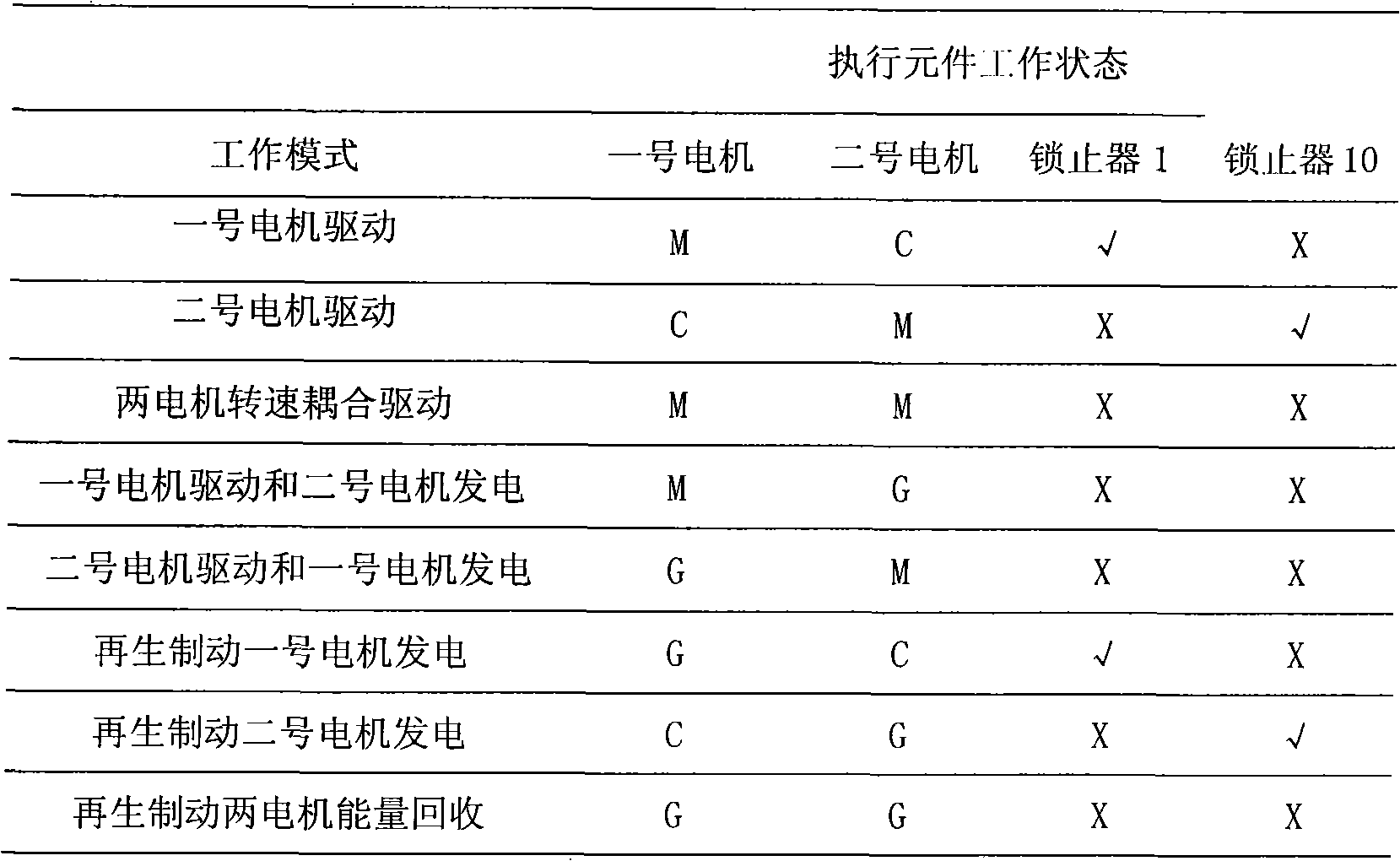

[0009] The present invention is composed of locking device 1, power input gear 2, No. 1 speed reducer 3, No. 1 motor 4, No. 1 controller 5, energy storage device 6, No. 2 controller 7, No. 2 motor 8, and No. 9, locking device 10, sun gear 11, ring gear outer teeth 12, ring gear inner teeth 13, planetary gear 14, planet carrier 15, driving wheel 16, characterized in that: No. 1 motor 4 and No. 2 motor 8 Arranged on the same side, and the shafts are arranged in parallel, the output power of the No. 1 motor 4 passes through the No. 1 reducer 3, the power input gear 2, and the outer gear of the ring gear 12; the output power of the No. 2 motor 8 passes through the No. 2 reducer 9 and the sun gear 11 , through the planetary gear to achieve speed coupling and output to the drive wheel 16 by the planetary carrier 15 .

[0010] The No. 1 controller 5 controls the working state and power output of the No. 1 moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com