Method for producing sulfuric acid by using waste gas containing hydrogen sulfide

A technology for producing hydrogen sulfide and sulfuric acid, applied in the chemical industry, can solve the problems of narrow application range, long process flow and high operating cost, and achieve the effects of wide application range, high heat recovery efficiency and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

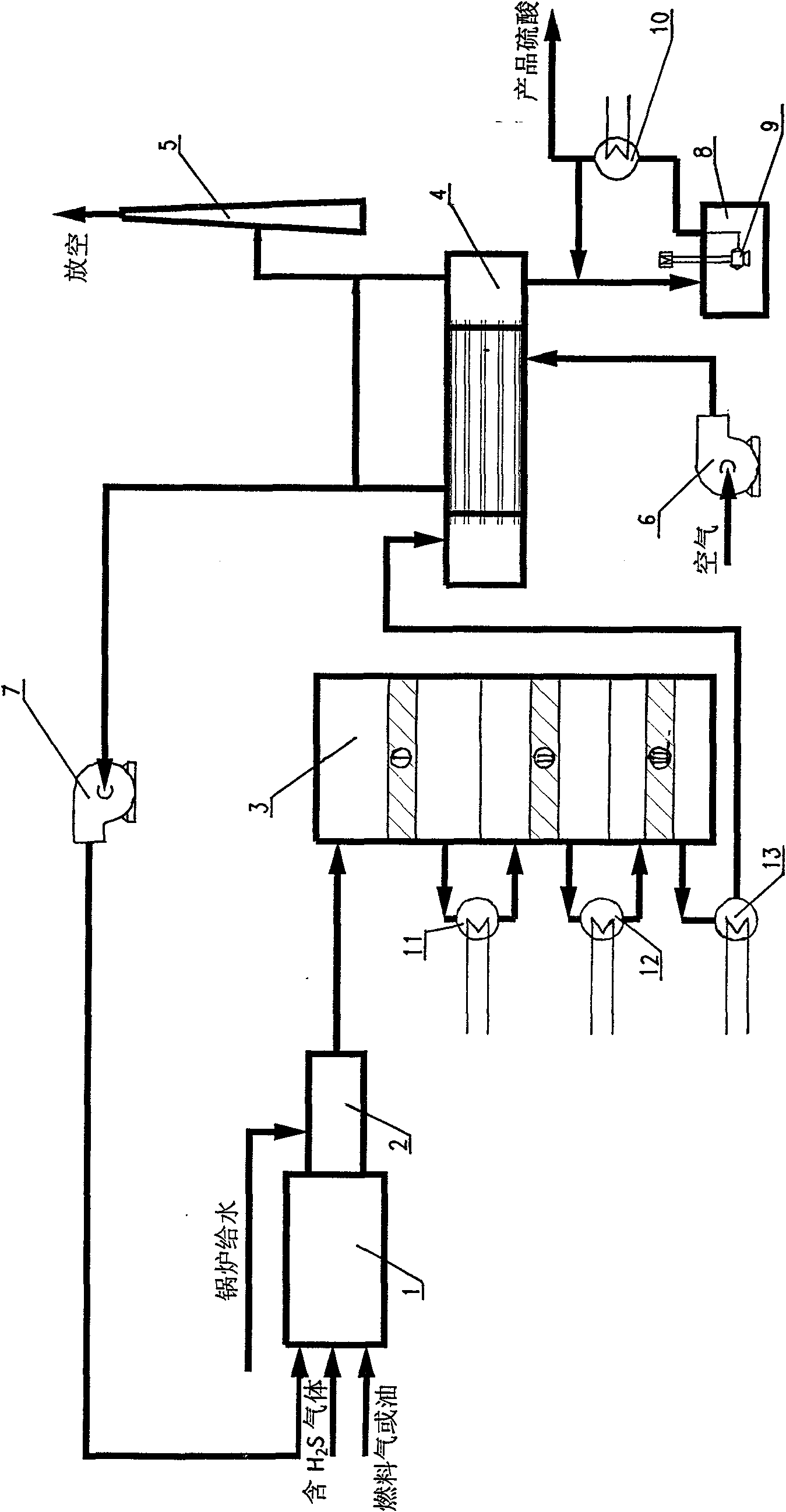

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the method for producing sulfuric acid from hydrogen sulfide waste gas of the present invention is illustrated by taking the synthetic ammonia of a certain plant as an example.

[0020] Exhaust gas conditions: temperature 33°C, pressure 2.2bar, gas composition as follows:

[0021] h 2 1.2385kmol / h

[0022] N 2 7.5866 kmol / h

[0023] CO 0.1586kmol / h

[0024] NH 3 0.1280kmol / h

[0025] HCN 0.0366kmol / h

[0026] CO 2 70.0807kmol / h

[0027] h 2 S 30.8949kmol / h

[0028] COS0.5392kmol / h

[0029] CH 3 OH 0.1541kmol / h

[0030] h 2 O 2.3429kmol / h

[0031] The exhaust gas from the above-mentioned ammonia synthesis unit and the preheated air at a temperature of 200-250°C enter the combustion furnace for combustion, and the sulfur-containing components such as hydrogen sulfide in the gas are completely burned to produce water and SO 2 , CO, NH in gas 3 , HCN and other components burn to produce CO 2 ,...

Embodiment 2

[0033] Embodiment 2: Take the sulfur-containing waste gas of a viscose factory as an example to illustrate the method for producing sulfuric acid from hydrogen sulfide waste gas according to the present invention. There are two streams of waste gas from the viscose factory, one is lean air with low sulfur content, which is mainly from the suction air of spinning and refining equipment, and contains H released from materials in the equipment. 2 S, CS 2 , COS; the other is rich gas with higher sulfur content, which comes from the evaporation of concentrated sulfuric acid for spinning, steam stripping of short filaments in wool laying tank, and degassing of viscose collagen solution. The indicators of these two materials are as follows:

[0034] 1. Poor gas condition

[0035] Flow: 78300Nm 3 / h

[0036] CS 2 : 12.5-13.9 / Nm 3 (319Nm3 / h, equivalent to 0.41mol%);

[0037] h 2 S: 1.62-1.80g / Nm 3 (93Nm3 / h, equivalent to 0.12mol%);

[0038] o 2 : 15584Nm 3 / h, 19.98mol%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com