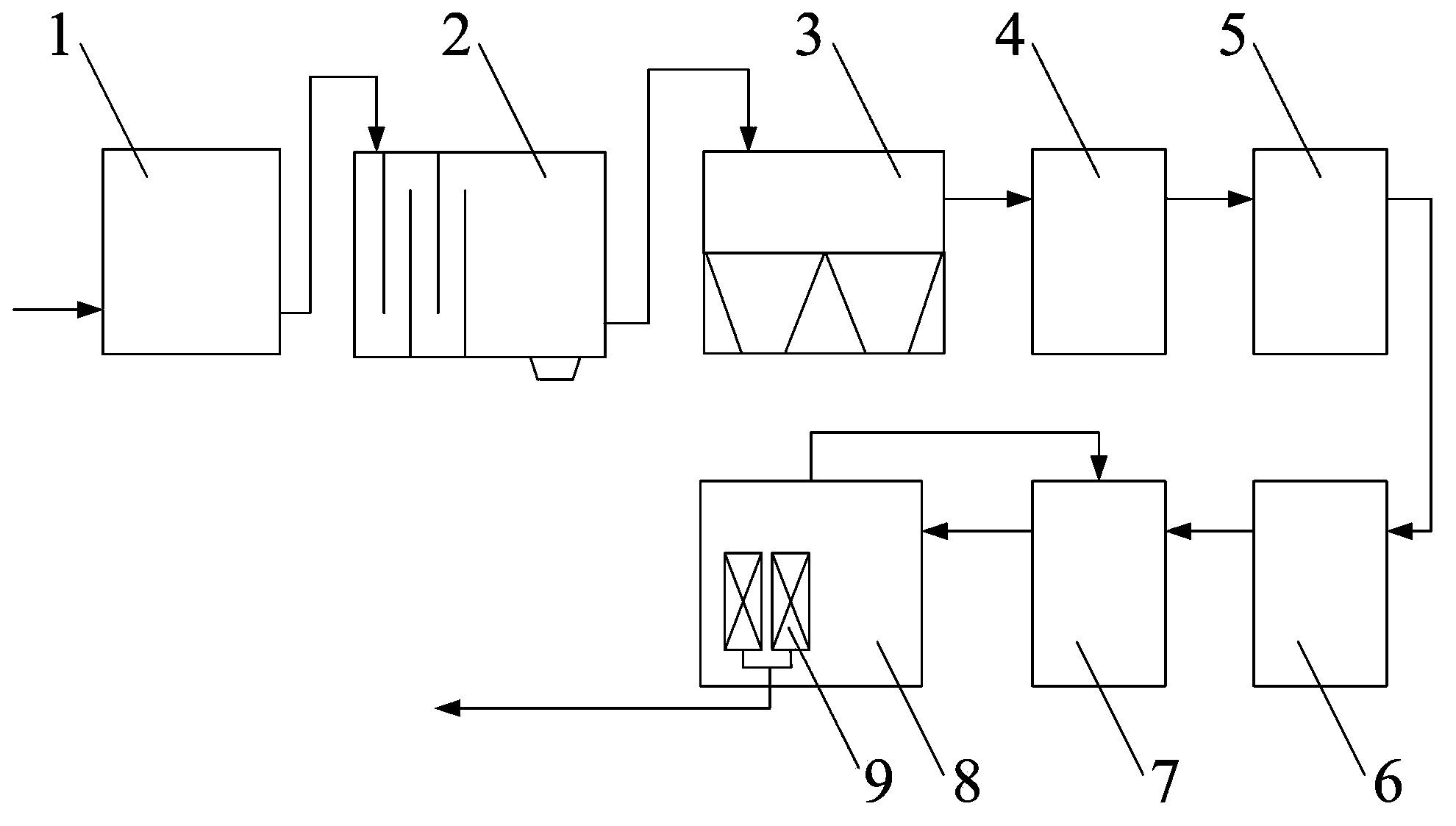

Coal chemical industry high-concentration wastewater treatment method and apparatus

A high-concentration wastewater and treatment device technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low flux and high membrane fouling, and achieve membrane cleaning frequency Low, reduced membrane fouling, simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A coal chemical process wastewater is treated by the method and device for the treatment of high-concentration coal chemical wastewater according to the present invention, and the treatment capacity is 1m 3 / h, raw water COD≥10000mg / L, ammonia nitrogen≥100mg / L, oil≥100mg / L, phenol≥100mg / L, water temperature 30°C~40°C. Effluent COD≤5mg / L, ammonia nitrogen≤0.5mg / L, oil≤1mg / L, phenol≤0.5mg / L, pH=6~9. Among them, the aerobic MBR device 8 was operated for 6 months, the transmembrane pressure (TMP) rose from 2kPa to 15kPa, and the membrane pressure increased steadily, and the aerobic MBR device 8 was continuously operated for 6 months without cleaning.

Embodiment 2

[0080] Wastewater from a coal-to-liquid synthetic oil section is treated by the method and device for treating high-concentration wastewater from coal chemical industry according to the present invention, and the treatment capacity is 0.3m 3 / h, raw water COD≥8000mg / L, ammonia nitrogen≥120mg / L, oil≥50mg / L, phenol≥100mg / L, water temperature 30°C~40°C. Effluent COD≤4mg / L, ammonia nitrogen≤0.5mg / L, oil≤1mg / L, phenol≤0.5mg / L, pH=6~9. Among them, the aerobic MBR device 8 was operated for 6 months, the transmembrane pressure (TMP) rose from 2kPa to 15kPa, and the membrane pressure increased steadily, and the aerobic MBR device 8 was continuously operated for 6 months without cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com