Preparation method of Ce modified Cu-Fe-SSZ-13 molecular sieve

A cu-fe-ce-ssz-13, molecular sieve technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of unsatisfactory hydrothermal stability, complex preparation process and high cost, and achieve The effect of improving the damage degree of the skeleton, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

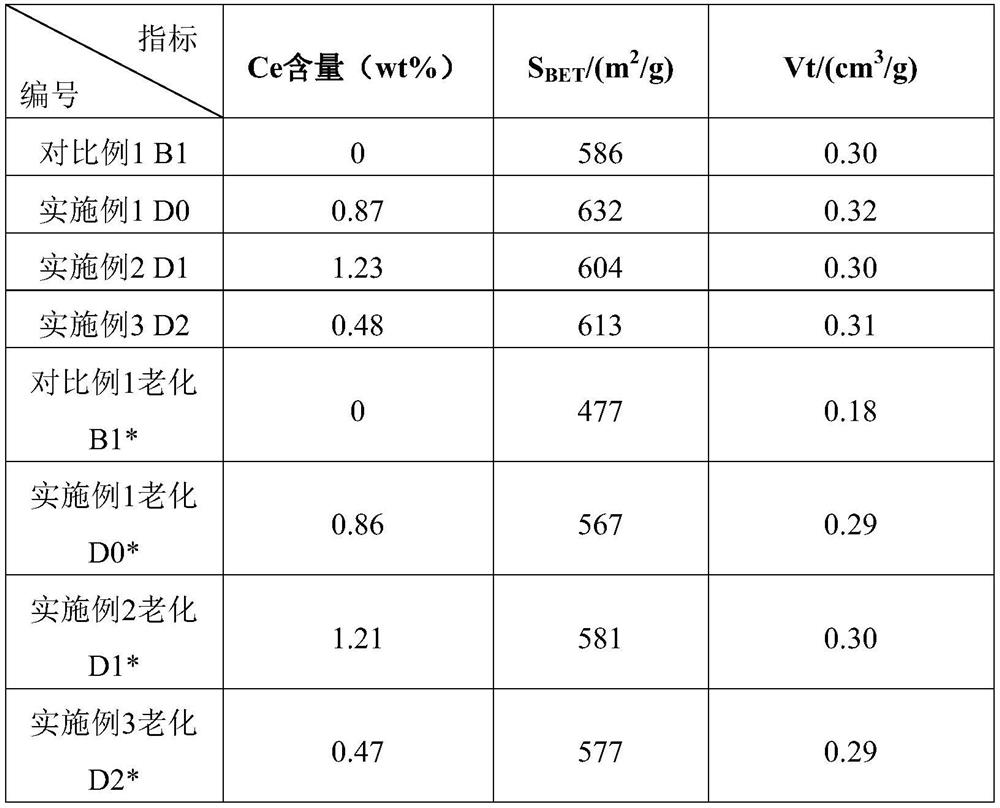

[0037] A kind of preparation method of Cu-Fe-Ce-SSZ-13 molecular sieve D0, comprises the steps:

[0038] (1) 2.7g CuSO 4 ·5H 2 Dissolve O in 15mL deionized water, stir well, add 14.88g tetraethylenepentamine (TEPA) dropwise, and continue stirring for 1 hour; then add 0.6g Ce(NO) 3 ·6H 2O and 4.8gFe(NO) 3 A solution fully dissolved in 33.78g of water, and then 10.4g of NaOH was added thereto to prepare A solution.

[0039] (2) Add 5.6gNaAlO to the A liquid prepared in step (1) 2 (41.0% Al by mass fraction 2 o 3 ), after stirring for 1 hour, add 60.0g silica sol (31.5% SiO by mass fraction 2 ), and then stirred for 2-3 hours, then put it into a polytetrafluoroethylene-lined steel reactor, aged for 12 hours, and subjected the obtained sol-gel precursor to a homogeneous hydrothermal reaction at 160°C for 72 hours, and crystallized After completion, centrifuge, wash with water to pH = 7, dry, and then calcined at 550° C. for 8 hours to obtain a Cu-Fe-Ce-SSZ-13 molecular sie...

Embodiment 2

[0047] A preparation method of Cu-Fe-Ce-SSZ-13 molecular sieve D1, comprising the steps of:

[0048] (3) 3.9g CuSO 4 ·5H 2 Dissolve O in 15ml deionized water, stir well, add 14.88g tetraethylenepentamine (TEPA) dropwise, continue stirring for 1 hour, then add 1.0g Ce(NO) 3 ·6H 2 O and 3.6gFe(NO) 3 Mix well and add 10.4g of NaOH to prepare liquid A.

[0049] (4) Add 5.6gNaAlO to the A liquid prepared in step (1) 2 (41.0% Al by mass fraction 2 o 3 ), after stirring for 1 hour, add 60.0g silica sol (31.5% SiO by mass fraction 2 ), and then stirred for 2-3 hours, then put it into a polytetrafluoroethylene-lined steel reactor, aged for 12 hours, and subjected the obtained sol-gel precursor to a homogeneous hydrothermal reaction at 160°C for 72 hours, and crystallized After completion, centrifuge, wash with water to pH = 7, dry, and then calcined at 550° C. for 8 hours to obtain a Cu-Fe-Ce-SSZ-13 molecular sieve catalyst.

[0050] The contents of Cu, Fe and Ce in the molecu...

Embodiment 3

[0052] A preparation method of Cu-Fe-Ce-SSZ-13 molecular sieve D2, comprising the steps of:

[0053] (1) 6.3g CuSO 4 ·5H 2 O was dissolved in 50ml of deionized water, stirred evenly, added dropwise 36.7g of tetraethylenepentamine (TEPA), continued to stir for 1 hour, and then added 1.5g of Ce(NO) 3 ·6H 2 O and 9.0gFe(NO) 3 A solution fully dissolved in 178.53g of water, and then 25.38g of NaOH was added thereto to obtain liquid A.

[0054] (2) Add 51.9g aluminum sulfate octadecahydrate in the A liquid that step (1) makes, add 60g solid silica gel (in terms of mass fraction 98%SiO2) after stirring for 1 hour 2 ), and then stirred for 2-3 hours, then put it into a polytetrafluoroethylene-lined steel reactor, aged for 12 hours, and subjected the obtained sol-gel precursor to a homogeneous hydrothermal reaction at 160°C for 96 hours, and crystallized After completion, centrifuge, wash with water to pH = 7, dry, and then calcined at 550° C. for 8 hours to obtain a Cu-Fe-Ce-SSZ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com