High-volume fly ash cement and preparation method thereof

A technology of fly ash cement with large dosage, applied in cement production, etc., can solve the problems of small internal specific surface area, small adsorption capacity, low utilization rate of fly ash, etc., and achieve the effect of increasing the dosage and promoting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

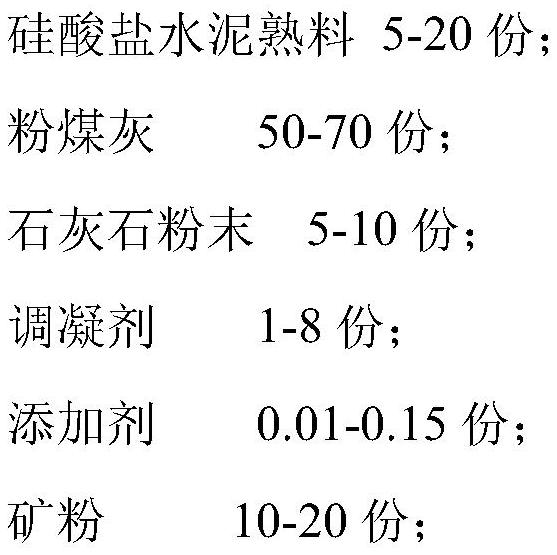

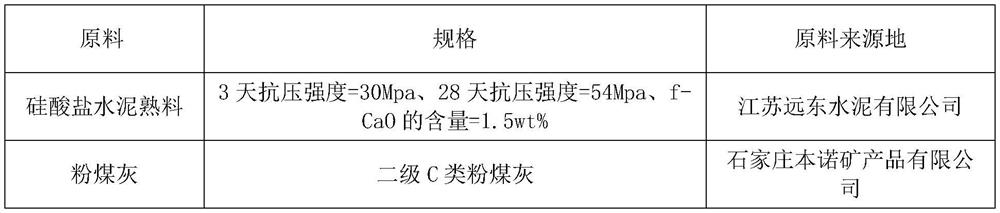

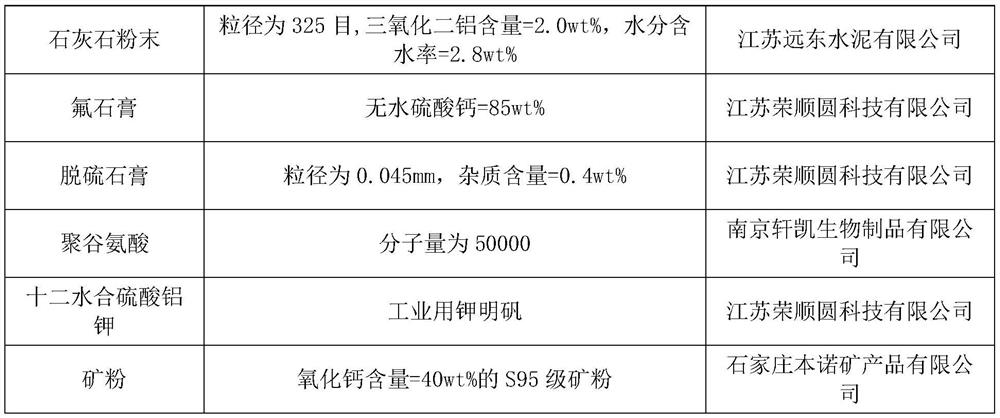

[0042] A kind of large-volume fly ash cement that embodiment 1-13 relates to, all with portland cement clinker, fly ash, fluorine gypsum, desulfurization gypsum, polyglutamic acid, dodecahydrate aluminum potassium sulfate and slag powder Made from raw materials.

[0043] The raw material ratio of embodiment 1-13 is as shown in table 2.

Embodiment 1

[0046] The preparation methods of Examples 1-13 are similar, and only Example 1 is taken as an example below for illustration.

[0047] The preparation method of embodiment 1 is as follows:

[0048] Step 1: Grinding Portland cement clinker, limestone powder, fly ash, fluorogypsum and desulfurized gypsum in a formula to obtain abrasives;

[0049] Step 2: adding the formula amount of mineral powder, polyglutamic acid and potassium aluminum sulfate dodecahydrate to the grinding material, and mixing evenly to obtain the primary mixture;

[0050] Step 3: Homogenize the initial mixture to obtain fly ash cement with large volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com