Elasticity-reducing low-sulfur alkali-free liquid setting accelerator and preparation method thereof

A quick-setting agent and liquid technology, applied in the field of quick-setting agent, can solve the problems of increasing the possibility of secondary ettringite, reducing the rebound rate of wet spraying process, and fast setting time of concrete, achieving no pungent smell, good Adaptability, fast setting time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

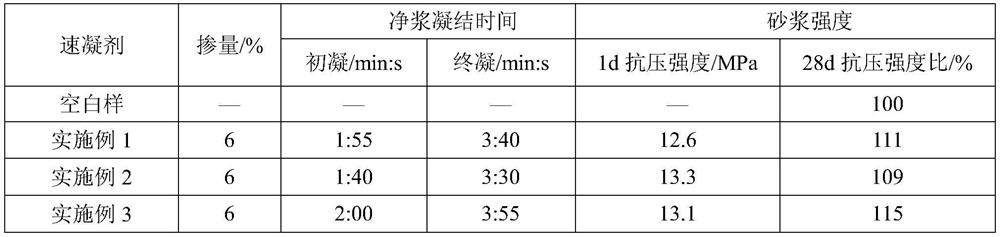

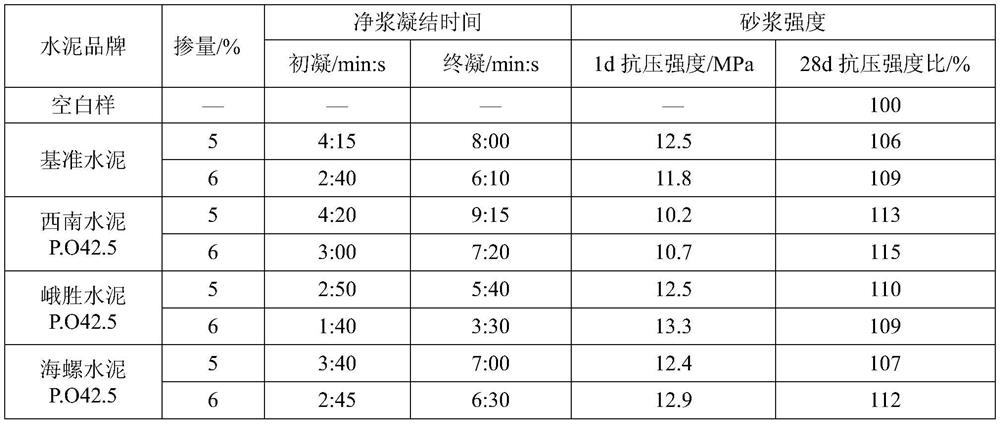

Embodiment 1

[0025] Embodiment 1: The bullet-reducing low-sulfur type non-alkali liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: 30% quick-setting component 1, 10% quick-setting component 2 , 2% quick-setting component three, 2.4% inorganic stabilizer, 4% organic reinforcing agent, 0.52% rebound inhibitor, 51.08% water. The above-mentioned quick-setting component 1 is aluminum sulfate octadecahydrate, the quick-setting component 2 is aluminum dihydrogen phosphate, the quick-setting component 3 is sodium metaaluminate, the above-mentioned inorganic stabilizer is phosphoric acid, and the above-mentioned organic strengthening agent is Diethanolamine, the rebound inhibitor mentioned above is formed by mixing hydroxypropyl methylcellulose, polyacrylamide, and redispersible latex powder in a certain proportion. The preparation method of described bullet-reducing low-sulfur type alkali-free liquid quick-setting age...

Embodiment 2

[0029] Embodiment 2: The bullet-reducing low-sulfur type alkali-free liquid quick-setting agent of the present invention is made of the raw materials of following components and mass percentage: 35% quick-setting component 1, 7% quick-setting component 2 , 2.5% quick-setting component three, 4% inorganic stabilizer, 4% organic reinforcing agent, 0.416% rebound inhibitor, 47.084% water. The above-mentioned quick-setting component 1 is aluminum sulfate octadecahydrate, the quick-setting component 2 is aluminum dihydrogen phosphate, the quick-setting component 3 is sodium metaaluminate, the above-mentioned inorganic stabilizer is sulfuric acid, and the above-mentioned organic strengthening agent is N-methyldiethanolamine, the rebound inhibitor mentioned above is formed by mixing hydroxypropyl methylcellulose, polyacrylamide, and redispersible latex powder in a certain proportion. The preparation method of described bullet-reducing low-sulfur type alkali-free liquid quick-setting ...

Embodiment 3

[0033] Embodiment 3: The bullet-reducing low-sulfur type alkali-free liquid quick-setting agent of the present invention is made of the following components and mass percentage raw materials: 28% quick-setting component one, 12% quick-setting component two , 1.5% quick-setting component three, 2.5% inorganic stabilizer, 3% organic reinforcing agent, 0.52% rebound inhibitor, 52.48% water. The above-mentioned quick-setting component 1 is aluminum sulfate octadecahydrate, the quick-setting component 2 is aluminum dihydrogen phosphate, the quick-setting component 3 is sodium metaaluminate, and the above-mentioned inorganic stabilizer is a combination of phosphoric acid and nitric acid. , the mass ratio of phosphoric acid to nitric acid is 1:2.5, and the above-mentioned organic reinforcing agent is the combination of two raw materials of N-methyldiethanolamine and diethanol monoisopropanolamine, N-methyldiethanolamine and diethanol monoisopropanolamine The mass ratio of propanolami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com