Environment-friendly water-based adhesive for root-resistant self-adhesion waterproof coiled material and preparation method thereof

A self-adhesive waterproofing membrane and anti-root puncture technology, applied in the field of adhesives for self-adhesive waterproofing membranes and preparation thereof, can solve the hazards of construction personnel and the environment, have no anti-plant root puncture function, and poor waterproof effect and other problems, to achieve the effect of obvious waterproof effect, compensation of material shrinkage, and excellent bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

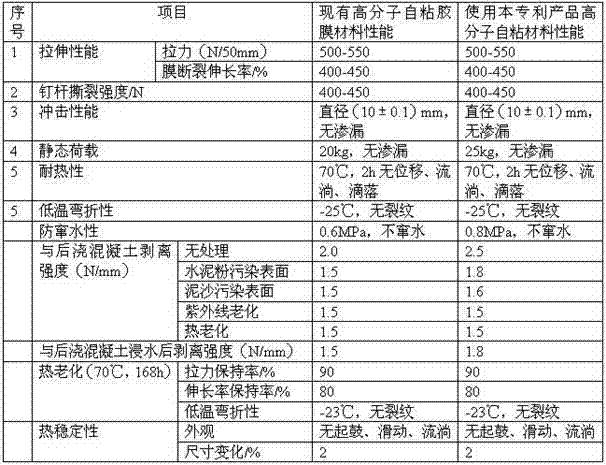

Image

Examples

Embodiment 1

[0041] Embodiment 1, the raw material composition of this anti-root puncture self-adhesive waterproof roll material with environment-friendly water-based adhesive composition is as follows by weight percentage:

[0042] Vinyl acetate-butyl acrylate copolymer 10%;

[0043] Sulfonated dehydroabietic acid disodium salt solution 20%;

[0044] Glycerin 10%;

[0045] Isopropanol 10%;

[0046] Methanol 10%;

[0047] Potassium sulfoaluminate dodecahydrate 3%;

[0050] Bentonite 5%;

[0051] Sodium silicate / sodium metasilicate 3%;

[0052] Sodium Lauryl Sulfonate 11%;

[0053] Nano silica 2%;

[0054] Nano Zinc Oxide 2%;

[0055] Silica fume powder 4%;

[0056] Polypropylene 2%.

[0057]

Embodiment 2

[0058] Embodiment 2, the raw material composition of this anti-root puncture self-adhesive waterproof roll material with environment-friendly water-based adhesive composition is as follows by weight percentage:

[0059] Vinyl acetate-butyl acrylate copolymer 3%;

[0060] Sulfonated dehydroabietic acid disodium salt solution 16%;

[0061] Glycerin 12%;

[0062] Isopropanol 12%;

[0063] Methanol 12%;

[0064] Potassium sulfoaluminate dodecahydrate 1%;

[0067] Bentonite 24%;

[0068] Sodium silicate / sodium metasilicate 1%;

[0069] Sodium dodecyl sulfonate 4%;

[0070] Nano silica 1%;

[0071] Nano Zinc Oxide 1%;

[0072] Silica fume powder 2%;

[0073] Polypropylene 1%.

[0074]

Embodiment 3

[0075] Embodiment 3, the raw material composition of this anti-root puncture self-adhesive waterproof roll material with environment-friendly water-based adhesive composition is as follows by weight percentage:

[0076] Vinyl acetate-butyl acrylate copolymer 4%;

[0077] Sulfonated dehydroabietic acid disodium salt solution 26%;

[0078] Glycerin 4%;

[0079] Isopropanol 4%;

[0080] Methanol 4%;

[0081] Potassium sulfoaluminate dodecahydrate 6%;

[0083] Calcium hydroxide 3%;

[0084] Bentonite 2%;

[0085] Sodium silicate / sodium metasilicate 6%;

[0086] Sodium Lauryl Sulfate 12%;

[0087] Nano silica 3%;

[0088] Nano Zinc Oxide 3%;

[0089] Silica fume powder 6%;

[0090] Polypropylene 5%.

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com