Coal gasification coarse slag-based composite flocculant as well as preparation method and application thereof

A composite flocculant and coal gasification technology, which is applied in the field of solid waste recycling to achieve the effects of simple preparation method and improved flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

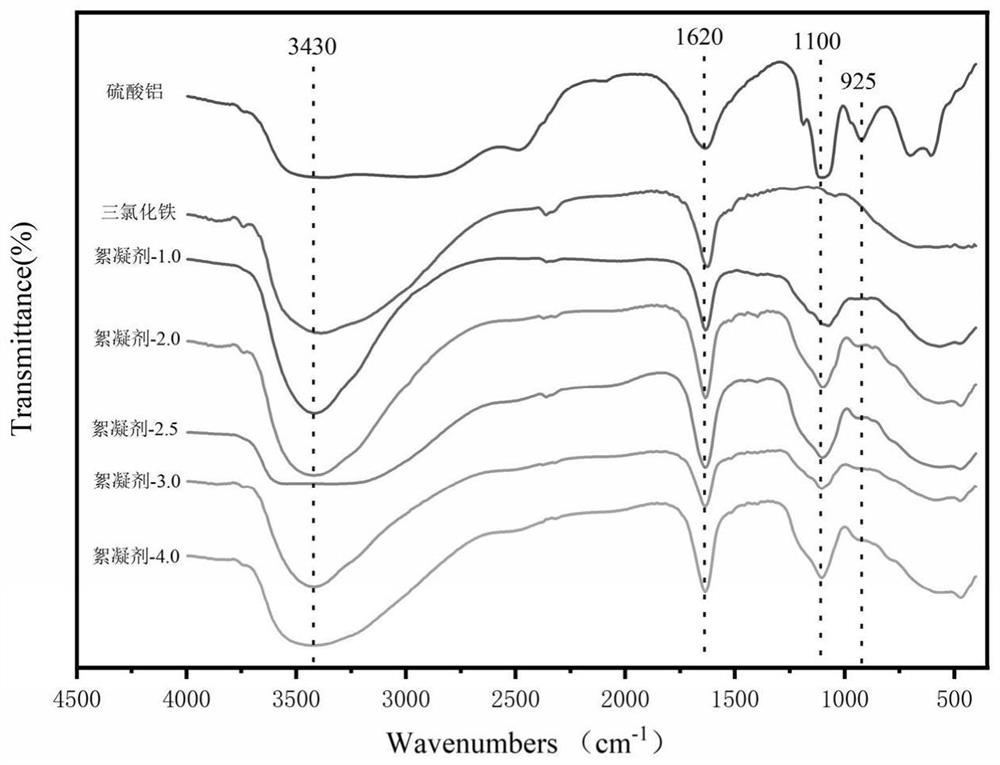

[0027] A preparation method of a coal gasification coarse slag-based composite flocculant: the specific steps are: accurately weigh 20.0 g of coal gasification coarse slag and place it in a 250 mL beaker, add 200 mL of hydrochloric acid of different concentrations (1.0mol / L, 2.0mol / L L, 2.5mol / L, 3.0mol / L, 4.0mol / L hydrochloric acid solution) is placed on a magnetic stirrer and stirred for a period of acid leaching, after the acid leaching process is finished, use a vacuum filter to carry out suction filtration, Separation, the resulting filtrate is used to prepare a composite flocculant, and the filter residue can be used for other purposes. After the filtrate is left to mature for a period of time in a sealed state at room temperature, fluorescent green colloidal substances are finally formed; the colloidal substances are dried and ground evenly to make a coal gasification coarse slag-based multi-ion composite flocculant.

[0028] After the filtrate is left to mature for a p...

Embodiment 1

[0047] Simulated wastewater testing. Weigh 0.5 g of different types of multi-ion composite flocculants and dissolve them in 100 mL of deionized water for ultrasonic dissolution to prepare a flocculant solution. Weigh 10.0g of kaolin and dissolve it in water to prepare waste water, and test the flocculation effect.

[0048] Take 7 beakers, accurately measure 200mL of wastewater into the beakers, add different amounts (0.0mL, 1.0mL, 3.0mL, 5.0mL, 7.0mL, 10.0mL, 15.0mL) of flocculant solutions, and then Stir rapidly at a speed of 250r / min for 3min to mix evenly, then slowly stir at a speed of 135r / min for 20min, and measure the turbidity of the wastewater after standing for 25min.

[0049] Table 4 Removal of simulated wastewater turbidity by different types of multi-ion composite flocculants

[0050]

Embodiment 2

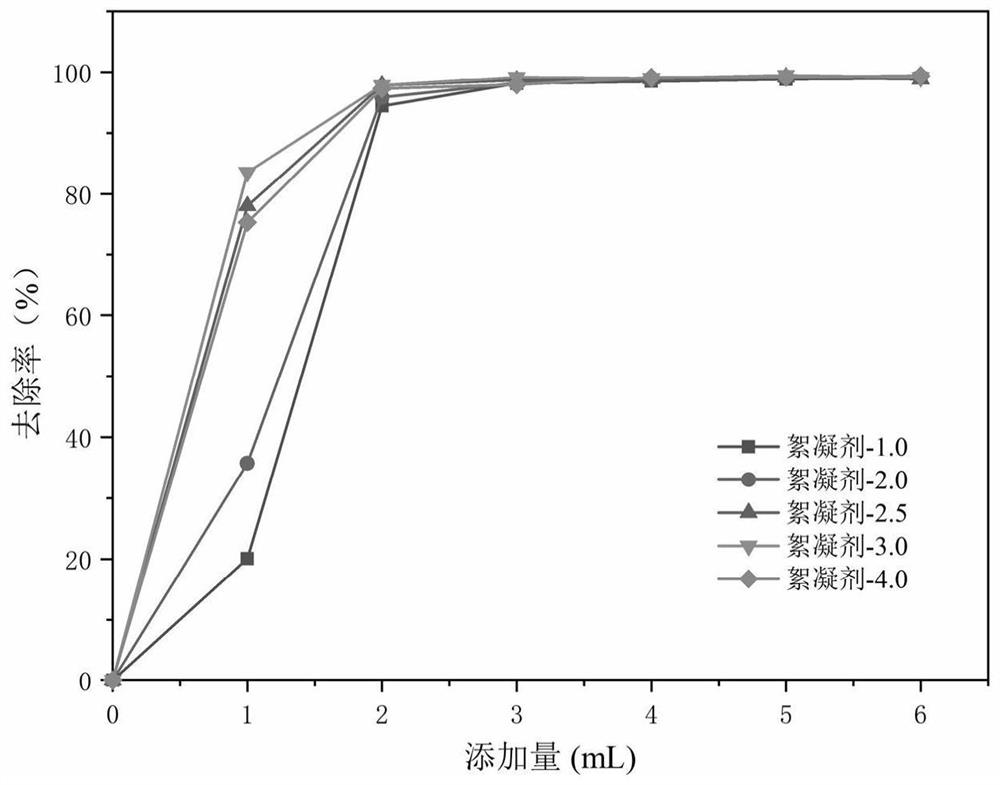

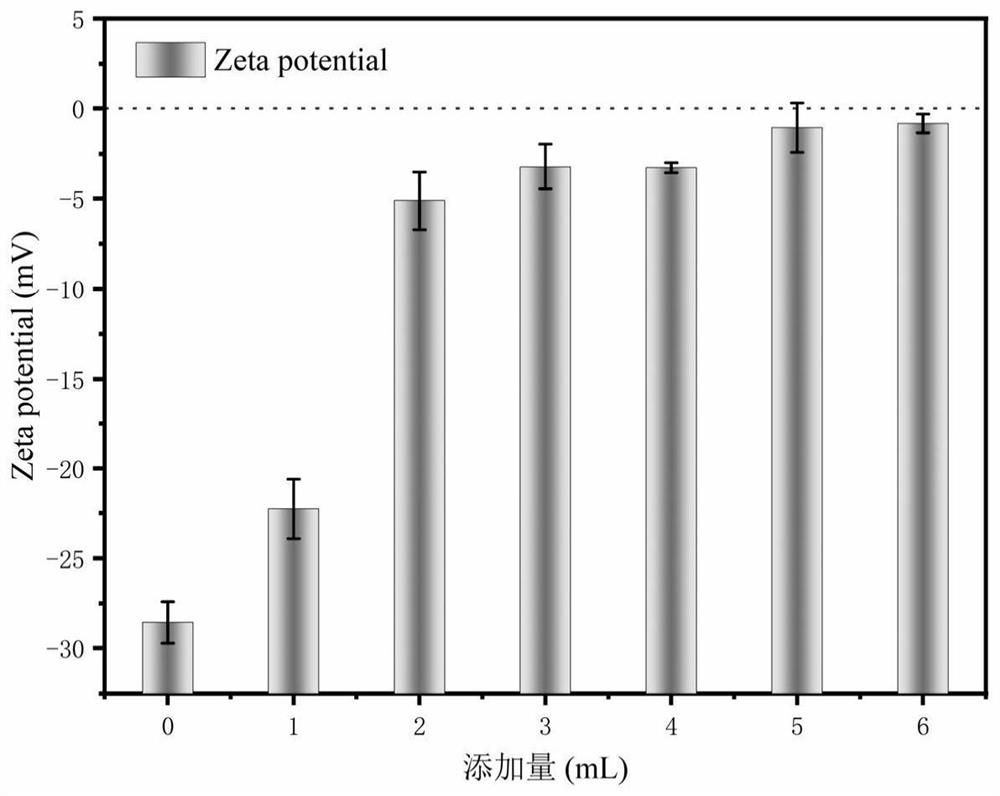

[0052] Simulate the removal of ammonia nitrogen from domestic wastewater. Weigh 0.5 g of self-made different types of multi-ion composite flocculants and dissolve them in 100 mL of deionized water for ultrasonic dissolution to prepare a flocculant solution. Weigh 10.0g of kaolin and 5.0g of ammonium chloride and dissolve in 5.0L of river wastewater to simulate domestic wastewater. Take 7 beakers, accurately measure 200mL of wastewater into the beaker, add different amounts (0.0mL, 1.0mL, 2.0mL, 3.0mL, 4.0mL, 5.0mL, 6.0mL) of flocculant solution, and then Stir quickly at a speed of 250r / min for 3 minutes to mix well, then slowly stir at a speed of 135r / min for 20 minutes, and measure the absorbance of ammonia nitrogen after standing for 25 minutes to test the treatment effect of the flocculant on ammonia nitrogen.

[0053] Table 5 Removal of ammonia nitrogen in simulated domestic wastewater by different types of multi-ion composite flocculants

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com